• Prepare maintenance space. |

• Do not drop or bump, or apply excess impact. |

• Do not pull the lead wire forcefully, not lift the product by pulling the lead |

wire. (Tensile force 49N or less). |

• Mount a sensor by observing the proper tightening torque. |

• Install or connect the flow sensor so that the flow direction specified on the |

label matches with actual flow direction. |

• Pipe the flow sensor after eliminating dust in piping by air blow to avoid |

failure and malfunction. |

• Use dry air which complies with the quality grade of ISO |

1.6.2 : 2001. |

• If the entering of foreign material to the fluid is possible, install and pipe the |

filter or the mist separator to the inle to avoid failure and malfunction. |

• Avoid repeatedly bending or stretching the lead wire. |

• Wire correctly. |

• Do not wire while the power is supplied. |

• Do not wire in conjunction with power lines or high voltage lines. |

• Wire as short as possible to avoid the affect of noise and surge. |

• Never use in the presence of explosive gases. |

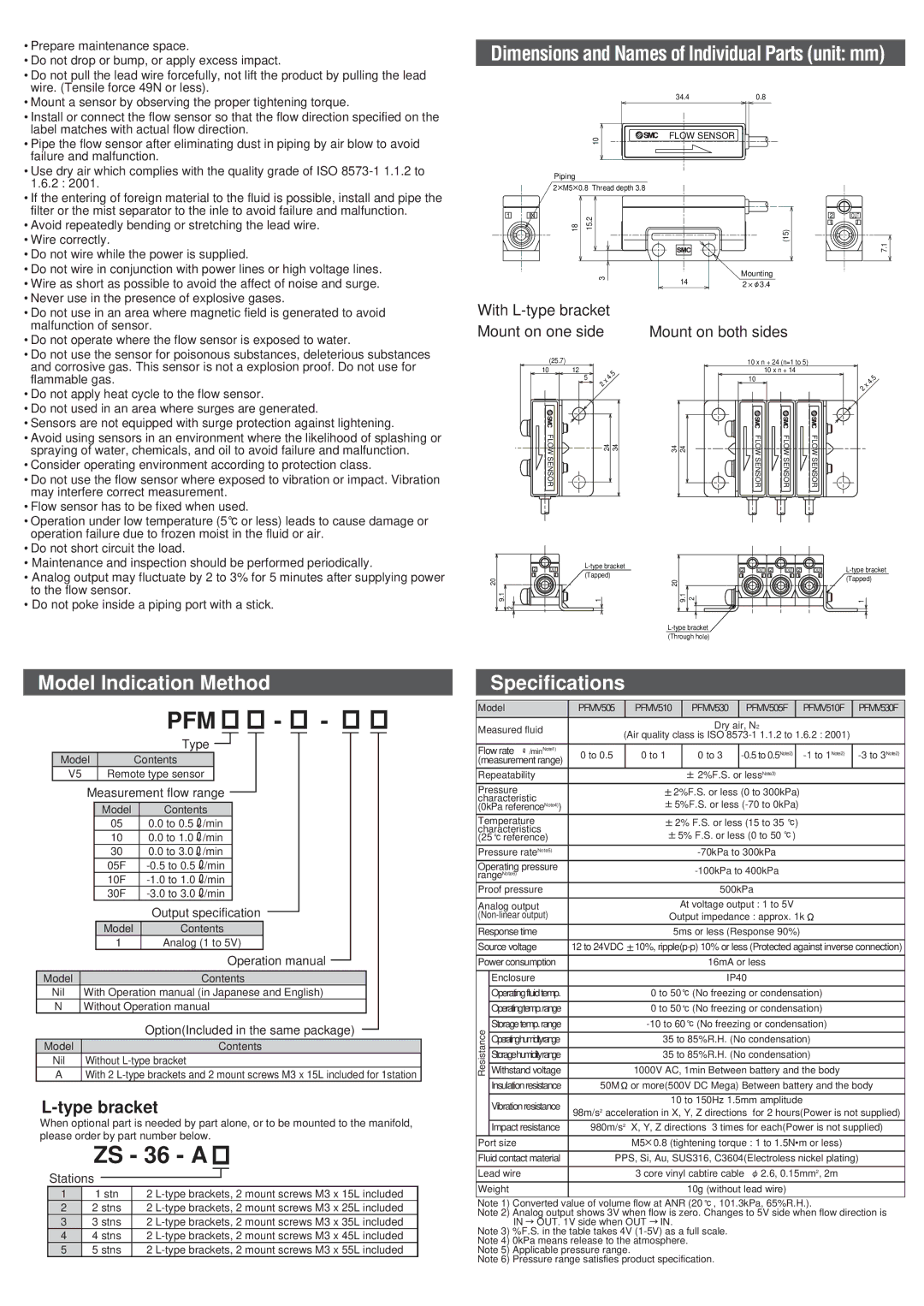

Dimensions and Names of Individual Parts (unit: mm)

34.40.8

|

| 10 | FLOW SENSOR |

|

|

|

|

|

|

| |

| Piping |

|

|

|

|

| 2 M5 | 0.8 Thread depth 3.8 |

|

|

|

1 | IN | 15.2 |

|

| 2 OUT |

| 18 |

|

| (15) | |

|

|

|

|

| 7.1 |

|

| 3 | 14 | Mounting | |

|

| 2 | 3.4 | ||

|

|

| |||

|

|

|

| ||

• Do not use in an area where magnetic field is generated to avoid |

malfunction of sensor. |

• Do not operate where the flow sensor is exposed to water. |

• Do not use the sensor for poisonous substances, deleterious substances |

and corrosive gas. This sensor is not a explosion proof. Do not use for |

flammable gas. |

• Do not apply heat cycle to the flow sensor. |

• Do not used in an area where surges are generated. |

• Sensors are not equipped with surge protection against lightening. |

• Avoid using sensors in an environment where the likelihood of splashing or |

spraying of water, chemicals, and oil to avoid failure and malfunction. |

• Consider operating environment according to protection class. |

• Do not use the flow sensor where exposed to vibration or impact. Vibration |

may interfere correct measurement. |

• Flow sensor has to be fixed when used. |

• Operation under low temperature (5 or less) leads to cause damage or |

operation failure due to frozen moist in the fluid or air. |

• Do not short circuit the load. |

• Maintenance and inspection should be performed periodically. |

With

(25.7) |

|

|

|

|

10 | 12 |

|

| .5 |

| 5 |

|

| |

|

| x | 4 | |

|

| 2 |

| |

|

|

|

| |

FLOW |

|

| 24 34 | |

SENSOR |

|

|

|

|

Mount on both sides

10 x n + 24 (n=1 to 5)

|

| 10 x n + 14 |

|

| 10 |

|

|

34 24 | FLOW | FLOW | FLOW |

| SENSOR | SENSOR | SENSOR |

|

| .5 |

| x | 4 |

2 |

| |

|

|

• Analog output may fluctuate by 2 to 3% for 5 minutes after supplying power |

to the flow sensor. |

• Do not poke inside a piping port with a stick. |

Model Indication Method

| PFM | - | - | |||||||

| Type |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| ||

Model | Contents |

|

|

|

|

|

|

|

|

|

V5 | Remote type sensor |

|

|

|

|

|

|

|

|

|

Measurement flow range

Model | Contents | |

05 | 0.0 to 0.5 | /min |

10 | 0.0 to 1.0 | /min |

30 | 0.0 to 3.0 | /min |

05F | /min | |

10F | /min | |

30F | /min | |

|

|

|

| Output specification |

|

|

| |||||

|

|

|

|

| ||||||||

|

|

| Model | Contents |

|

|

|

|

|

|

|

|

|

| 1 | Analog (1 to 5V) |

|

|

|

|

|

|

|

| |

|

|

|

| Operation manual |

|

|

|

|

| |||

|

|

|

|

| ||||||||

|

|

|

|

|

| |||||||

Model |

|

|

| Contents |

|

| ||||||

Nil | With Operation manual (in Japanese and English) |

|

| |||||||||

N | Without Operation manual |

| ||||||||||

|

|

|

| Option(Included in the same package) |

|

|

| |||||

|

|

|

|

|

| |||||||

Model |

|

|

| Contents | ||||||||

Nil | Without | |||||||||||

A | With 2 | |||||||||||

2 | OUT |

| 2 | OUT 2 | OUT 2 | OUT | ||

(Tapped) |

| |||||||

20 |

| 20 |

|

|

|

| (Tapped) | |

|

|

|

|

|

| |||

|

|

|

|

|

|

| ||

9.1 |

| 1 | 9.1 | 2 |

|

|

| 1 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| (Through hole) |

|

|

|

| |

Specifications

Model | PFMV505 | PFMV510 |

| PFMV530 | PFMV505F | PFMV510F | PFMV530F | ||

Measured fluid |

|

|

| Dry air, N2 |

|

|

| ||

| (Air quality class is ISO |

| |||||||

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

Flow rate /minNote1) | 0 to 0.5 | 0 to 1 |

| 0 to 3 | Note2) | Note2) | Note2) | ||

(measurement range) |

|

| |||||||

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

Repeatability |

|

|

| 2%F.S. or lessNote3) |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

Pressure |

|

| 2%F.S. or less (0 to 300kPa) |

|

| ||||

characteristic |

|

| 5%F.S. or less |

|

| ||||

(0kPa referenceNote4)) |

|

|

|

| |||||

Temperature |

|

| 2% F.S. or less (15 to 35 | ) |

|

| |||

characteristics |

|

| 5% F.S. or less (0 to 50 ) |

|

| ||||

(25 reference) |

|

|

|

| |||||

Pressure rateNote5) |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |

Operating pressure |

|

|

|

|

|

| |||

rangeNote6) |

|

|

|

|

|

| |||

Proof pressure |

|

|

| 500kPa |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

Analog output |

|

| At voltage output : 1 to 5V |

|

|

| |||

| Output impedance : approx. 1k |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

Response time |

|

| 5ms or less (Response 90%) |

|

| ||||

|

|

|

|

|

|

|

| ||

Source voltage | 12 to 24VDC | 10%, | |||||||

|

|

|

|

|

|

|

|

|

|

Power consumption |

|

|

| 16mA or less |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| Enclosure |

|

|

| IP40 |

|

|

| |

|

|

|

|

|

|

|

|

| |

| Operatingfluidtemp. |

| 0 to 50 (No freezing or condensation) |

|

| ||||

|

|

|

|

|

|

|

|

| |

| Operating temp. range |

| 0 to 50 (No freezing or condensation) |

|

| ||||

|

|

|

|

|

|

|

|

| |

Resistance | Storagetemp.range |

|

|

| |||||

|

|

|

|

|

|

| |||

Withstand voltage |

| 1000V AC, 1min Between battery and the body |

| ||||||

| Operatinghumidityrange |

| 35 to 85%R.H. (No condensation) |

|

| ||||

| Storage humidity range |

| 35 to 85%R.H. (No condensation) |

|

| ||||

|

|

|

|

|

|

|

|

|

|

| Insulationresistance | 50M | or more(500V DC Mega) Between battery and the body | ||||||

|

|

|

|

|

|

|

|

|

|

L-type bracket

Vibrationresistance

10 to 150Hz 1.5mm amplitude

When optional part is needed by part alone, or to be mounted to the manifold, please order by part number below.

ZS - 36 - A

Stations

1 | 1 stn | 2 |

2 | 2 stns | 2 |

3 | 3 stns | 2 |

4 | 4 stns | 2 |

5 | 5 stns | 2 |

98m/s2 acceleration in X, Y, Z directions for 2 hours(Power is not supplied)

Impact resistance | 980m/s2 X, Y, Z directions | 3 times for each(Power is not supplied) |

Port size | M5 0.8 (tightening torque : 1 to 1.5N•m or less) | |

|

| |

Fluid contact material | PPS, Si, Au, SUS316, C3604(Electroless nickel plating) | |

|

| |

Lead wire | 3 core vinyl cabtire cable 2.6, 0.15mm2, 2m | |

|

| |

Weight | 10g (without lead wire) | |

|

|

|

Note 1) Converted value of volume flow at ANR (20 | , 101.3kPa, 65%R.H.). | |

Note 2) Analog output shows 3V when flow is zero. Changes to 5V side when flow direction is IN ![]() OUT. 1V side when OUT

OUT. 1V side when OUT ![]() IN.

IN.

Note 3) %F.S. in the table takes 4V

Note 5) Applicable pressure range.

Note 6) Pressure range satisfies product specification.