Instructions for the installer

8. GAS CONNECTION

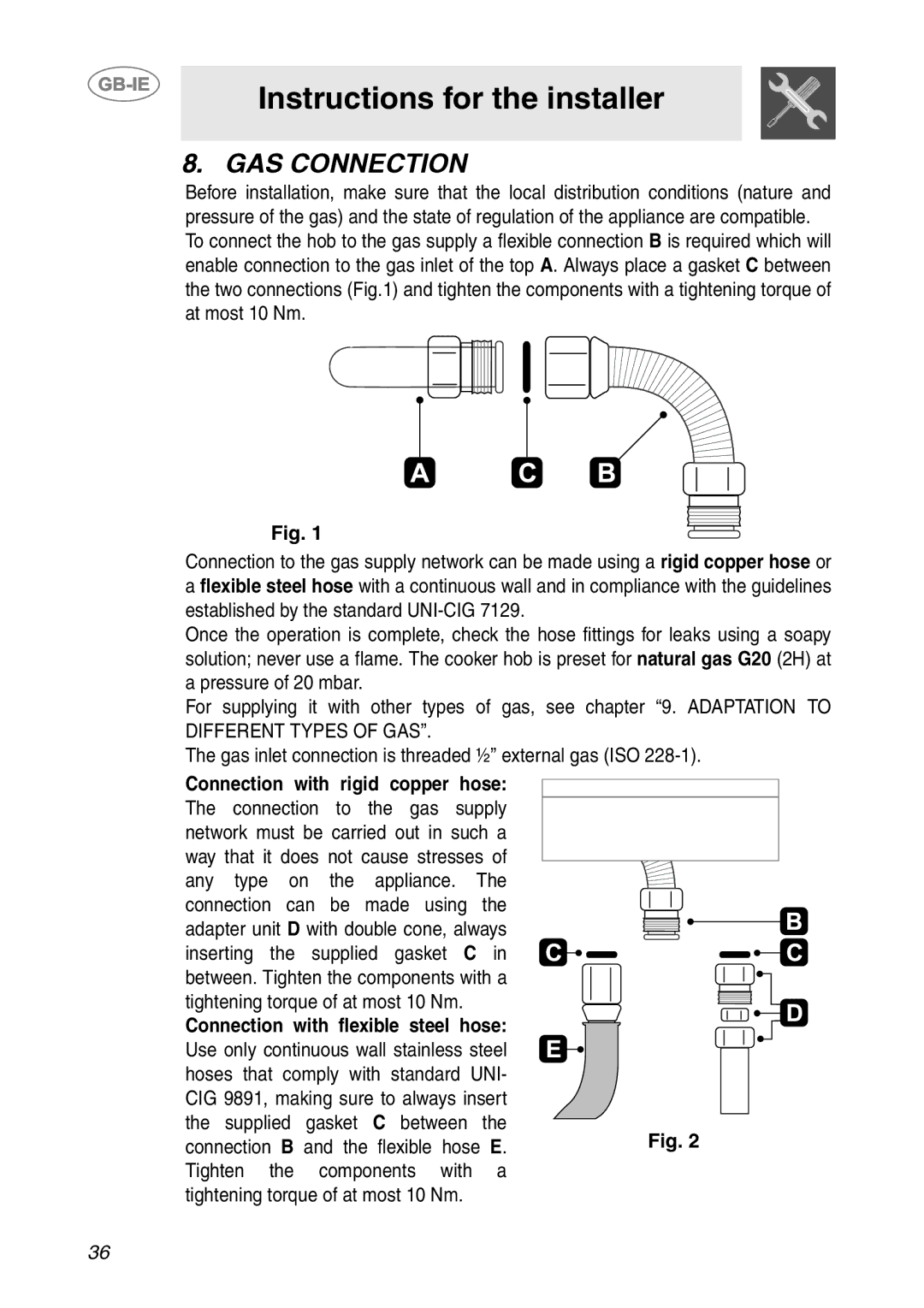

Before installation, make sure that the local distribution conditions (nature and pressure of the gas) and the state of regulation of the appliance are compatible. To connect the hob to the gas supply a flexible connection B is required which will enable connection to the gas inlet of the top A. Always place a gasket C between the two connections (Fig.1) and tighten the components with a tightening torque of at most 10 Nm.

Fig. 1

Connection to the gas supply network can be made using a rigid copper hose or a flexible steel hose with a continuous wall and in compliance with the guidelines established by the standard

Once the operation is complete, check the hose fittings for leaks using a soapy solution; never use a flame. The cooker hob is preset for natural gas G20 (2H) at a pressure of 20 mbar.

For supplying it with other types of gas, see chapter “9. ADAPTATION TO DIFFERENT TYPES OF GAS”.

The gas inlet connection is threaded ½” external gas (ISO

Connection with rigid copper hose:

The connection to the gas supply network must be carried out in such a way that it does not cause stresses of any type on the appliance. The connection can be made using the adapter unit D with double cone, always inserting the supplied gasket C in between. Tighten the components with a tightening torque of at most 10 Nm.

Connection with flexible steel hose:

Use only continuous wall stainless steel |

|

|

hoses that comply with standard UNI- |

|

|

CIG 9891, making sure to always insert |

|

|

the supplied gasket C between the |

| Fig. 2 |

connection B and the flexible hose E. |

| |

Tighten the components with a |

|

|

tightening torque of at most 10 Nm. |

|

|

36