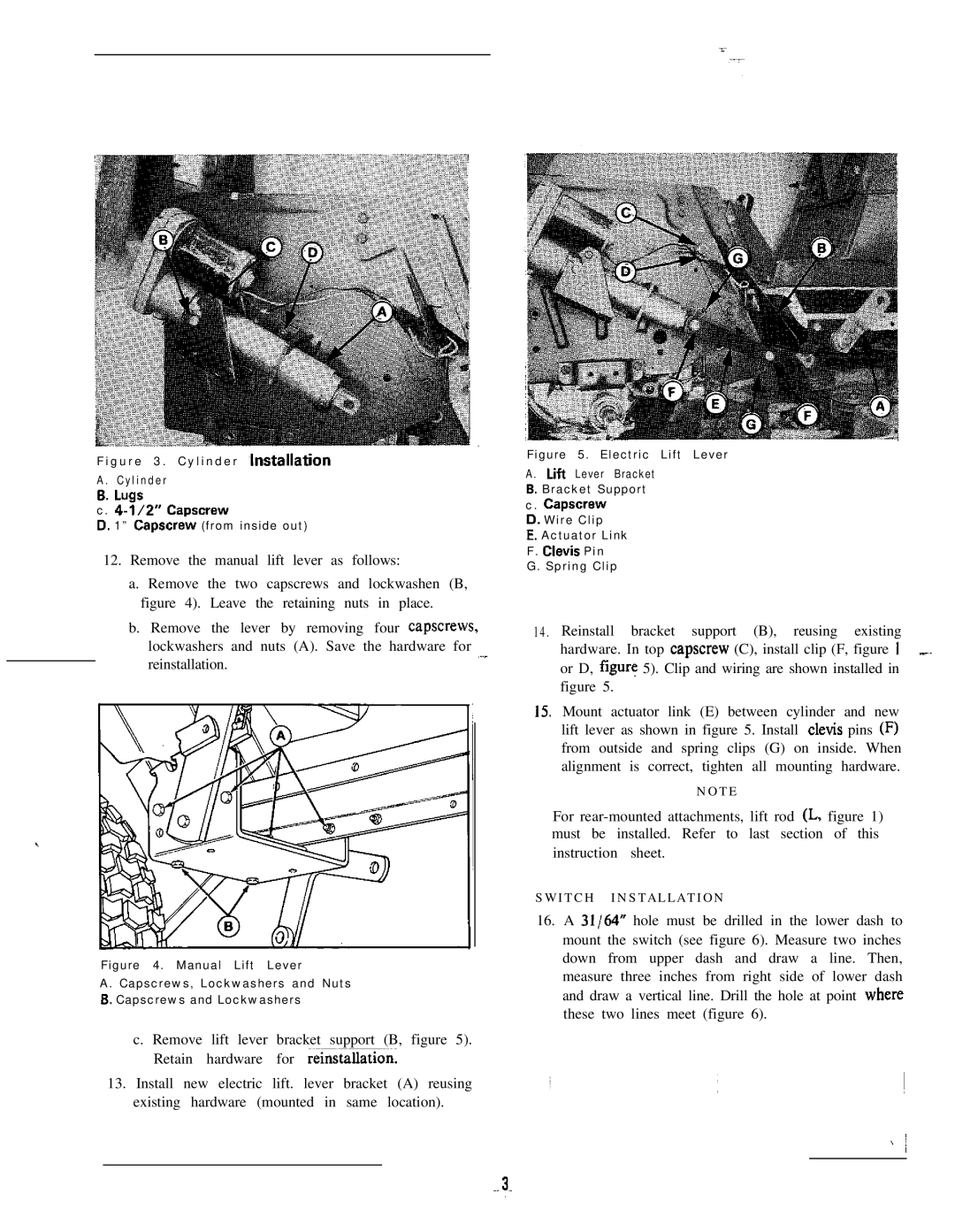

Figure 3 . Cylinder ~lnstallation

A . Cylinder

6.Lugs

c. 4-l/2” Capscrew

D. 1” Capscrew (from inside out)

12.Remove the manual lift lever as follows:

a.Remove the two capscrews and lockwashen (B, figure 4). Leave the retaining nuts in place.

b.Remove the lever by removing four capscrews,

lockwashers and nuts (A). Save the hardware for ,~~. reinstallation.

!

![]() .

.

Figure 4. Manual Lift Lever

A. Capscrews, Lockwashers and Nuts

B.Capscrews and Lockwashers

~

~

c.Remove lift lever bracket support (B, figure 5). Retain hardware for reinsta%nl

13.Install new electric lift. lever bracket (A) reusing existing hardware (mounted in same location).

Figure 5. Electric Lift Lever

A. Lift Lever Bracket

S.Bracket Support c. capscrew

D. Wire Clip

E.Actuator Link

F.Clevis Pin

G.Spring Clip

14 . Reinstall bracket support (B), reusing existing hardware. In top capscrew (C), install clip (F, figure I ..~ or D, figure 5). Clip and wiring are shown installed in figure 5.

15.Mount actuator link (E) between cylinder and new lift lever as shown in figure 5. Install clevis pins (F) from outside and spring clips (G) on inside. When alignment is correct, tighten all mounting hardware.

NOTE

For

SWITCH INSTALLATION

16.A 31/64” hole must be drilled in the lower dash to mount the switch (see figure 6). Measure two inches down from upper dash and draw a line. Then, measure three inches from right side of lower dash and draw a vertical line. Drill the hole at point where these two lines meet (figure 6).