250 Z & Javelin Series

Torque Mower Blades

![]() WARNING

WARNING

For your personal safety, blade mounting hardware must each be installed with two washers, then securely tightened to noted torque.

1.Check that blades are installed with the tabs pointing up toward deck as shown in Figure 5. Secure with a nut, and two blade washers, concave side up. Use a wooden block to prevent blade rotation and torque nut to

Lubrication

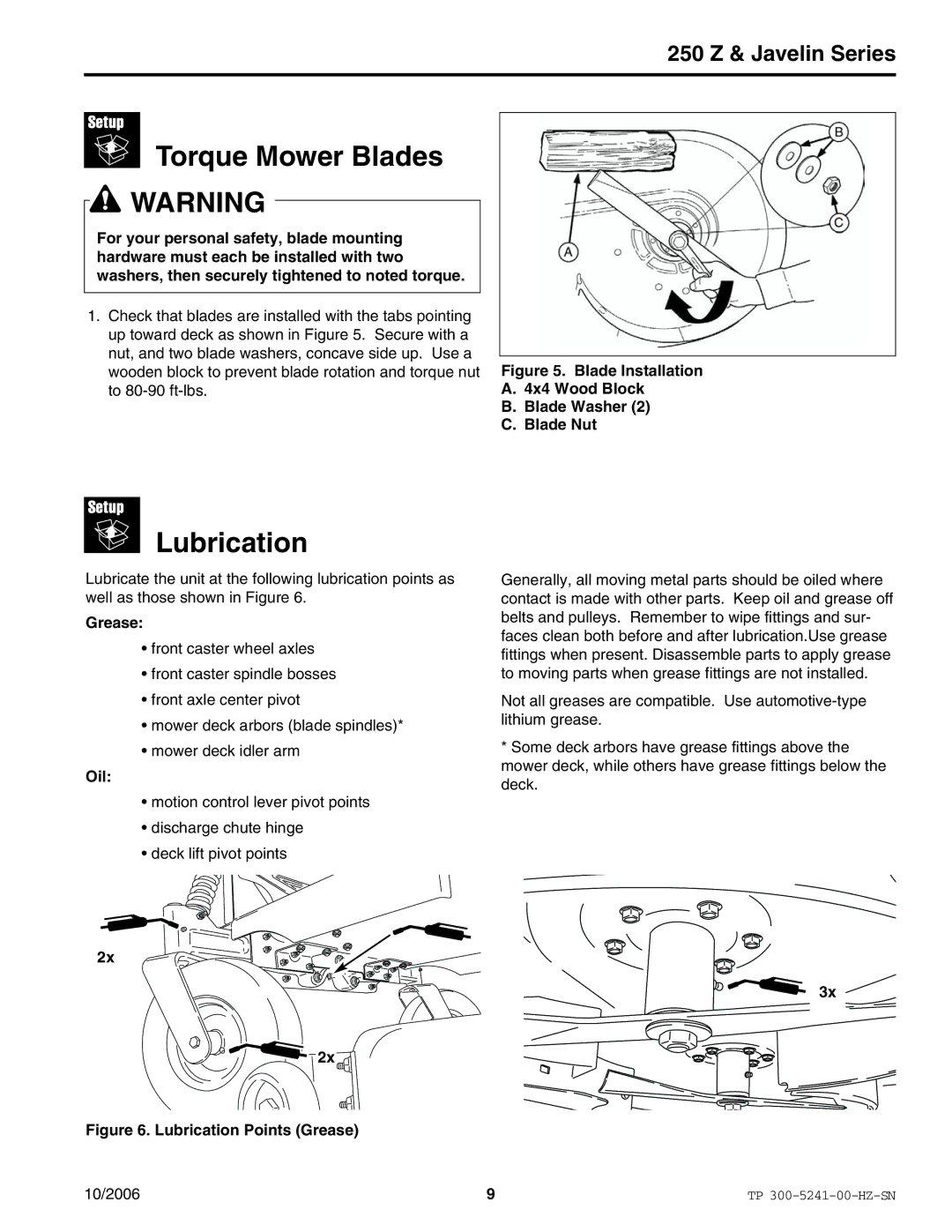

Lubricate the unit at the following lubrication points as well as those shown in Figure 6.

Grease:

•front caster wheel axles

•front caster spindle bosses

•front axle center pivot

•mower deck arbors (blade spindles)*

•mower deck idler arm

Oil:

•motion control lever pivot points

•discharge chute hinge

•deck lift pivot points

2x

![]() 2x

2x

Figure 6. Lubrication Points (Grease)

Figure 5. Blade Installation

A.4x4 Wood Block

B.Blade Washer (2)

C.Blade Nut

Generally, all moving metal parts should be oiled where contact is made with other parts. Keep oil and grease off belts and pulleys. Remember to wipe fittings and sur- faces clean both before and after lubrication.Use grease fittings when present. Disassemble parts to apply grease to moving parts when grease fittings are not installed.

Not all greases are compatible. Use

*Some deck arbors have grease fittings above the mower deck, while others have grease fittings below the deck.

3x

10/2006 | 9 | TP |