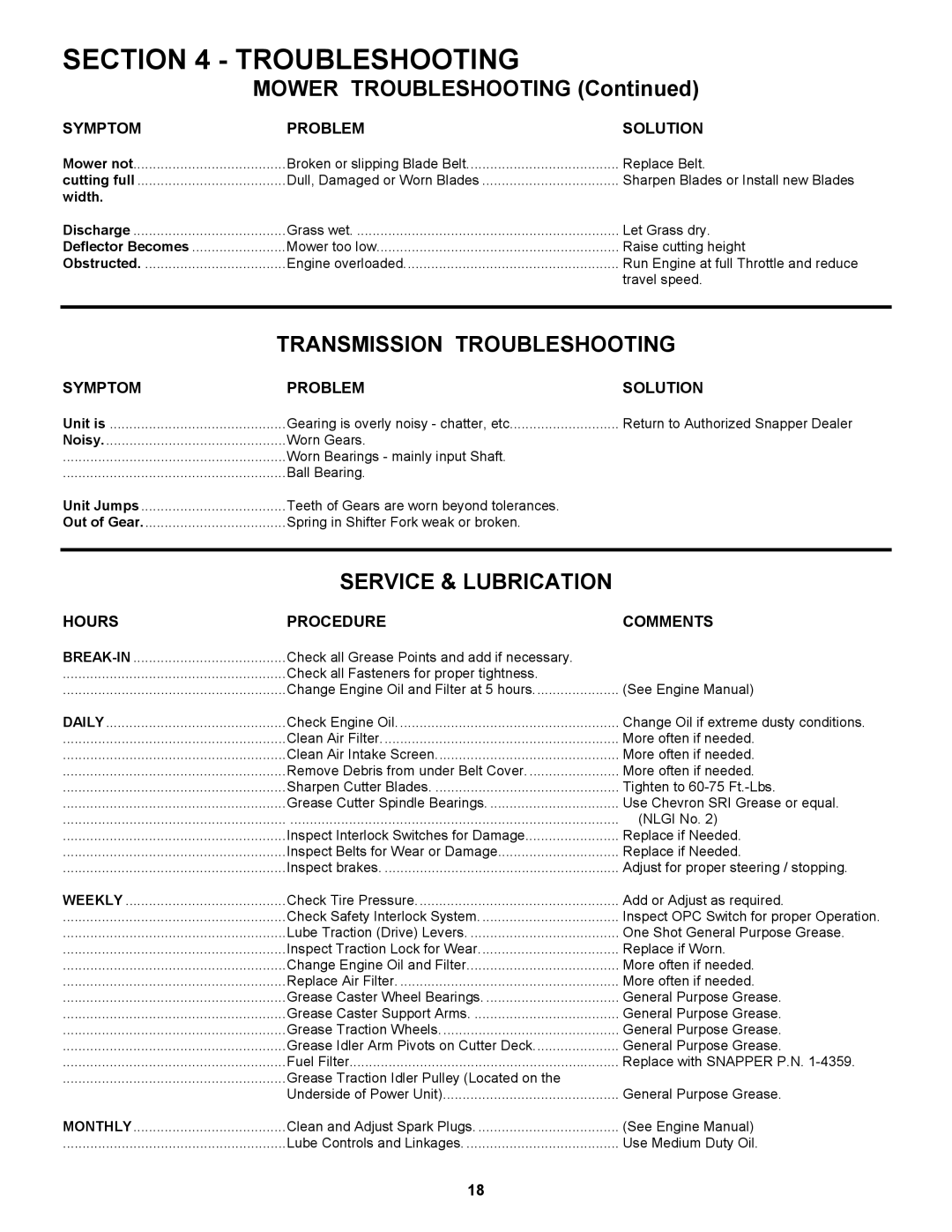

SECTION 4 - TROUBLESHOOTING

MOWER TROUBLESHOOTING (Continued)

SYMPTOM | PROBLEM | SOLUTION |

Mower not | Broken or slipping Blade Belt | Replace Belt. |

cutting full | Dull, Damaged or Worn Blades | Sharpen Blades or Install new Blades |

width. |

|

|

Discharge | Grass wet | Let Grass dry. |

Deflector Becomes | Mower too low | Raise cutting height |

Obstructed | Engine overloaded | Run Engine at full Throttle and reduce |

|

| travel speed. |

|

|

|

TRANSMISSION TROUBLESHOOTING

SYMPTOM | PROBLEM | SOLUTION |

Unit is | Gearing is overly noisy - chatter, etc | Return to Authorized Snapper Dealer |

Noisy | Worn Gears. |

|

......................................................... | Worn Bearings - mainly input Shaft. |

|

......................................................... | Ball Bearing. |

|

Unit Jumps | Teeth of Gears are worn beyond tolerances. |

|

Out of Gear | Spring in Shifter Fork weak or broken. |

|

|

|

|

SERVICE & LUBRICATION

HOURS | PROCEDURE | COMMENTS |

| Check all Grease Points and add if necessary. |

|

......................................................... | Check all Fasteners for proper tightness. |

|

......................................................... | Change Engine Oil and Filter at 5 hours | (See Engine Manual) |

DAILY | Check Engine Oil | Change Oil if extreme dusty conditions. |

......................................................... | Clean Air Filter | More often if needed. |

......................................................... | Clean Air Intake Screen | More often if needed. |

......................................................... | Remove Debris from under Belt Cover | More often if needed. |

......................................................... | Sharpen Cutter Blades | Tighten to |

......................................................... | Grease Cutter Spindle Bearings | Use Chevron SRI Grease or equal. |

......................................................... | .................................................................................... | (NLGI No. 2) |

......................................................... | Inspect Interlock Switches for Damage | Replace if Needed. |

......................................................... | Inspect Belts for Wear or Damage | Replace if Needed. |

......................................................... | Inspect brakes | Adjust for proper steering / stopping. |

WEEKLY | Check Tire Pressure | Add or Adjust as required. |

......................................................... | Check Safety Interlock System | Inspect OPC Switch for proper Operation. |

......................................................... | Lube Traction (Drive) Levers | One Shot General Purpose Grease. |

......................................................... | Inspect Traction Lock for Wear | Replace if Worn. |

......................................................... | Change Engine Oil and Filter | More often if needed. |

......................................................... | Replace Air Filter | More often if needed. |

......................................................... | Grease Caster Wheel Bearings | General Purpose Grease. |

......................................................... | Grease Caster Support Arms | General Purpose Grease. |

......................................................... | Grease Traction Wheels | General Purpose Grease. |

......................................................... | Grease Idler Arm Pivots on Cutter Deck | General Purpose Grease. |

......................................................... | Fuel Filter | Replace with SNAPPER P.N. |

......................................................... | Grease Traction Idler Pulley (Located on the |

|

| Underside of Power Unit) | General Purpose Grease. |

MONTHLY | Clean and Adjust Spark Plugs | (See Engine Manual) |

......................................................... | Lube Controls and Linkages | Use Medium Duty Oil. |

18