SECTION 4

MECHANICAL ADJUSTMENTS

1. Clean the following parts with a

swab: |

|

playback head | pinch roller |

rubber belt | capstan |

idler |

|

2.Demagnetize the playback head with a head demagnetizer.

3.Do not use a magnetized screwdriver for the adjustments.

4.After the adjustments, apply suitable locking compound to the parts adjusted.

5.The adjustments should be performed with the power supply voltage unless otherwise noted.

• Torque Measurement

Mode | Torque Meter | Meter Reading | |

|

|

| |

Forward | 30 – 65 g•cm | ||

(0.42 – 0.90 oz•inch) | |||

|

| ||

Forward | 0.5 – 4.5 g•cm | ||

Back Tension | (0.01 – 0.06 oz•inch) | ||

| |||

|

|

| |

Reverse | 30 – 65 g•cm | ||

(0.42 – 0.90 oz•inch) | |||

|

| ||

Reverse | 0.5 – 4.5 g•cm | ||

Back Tension | (0.01 – 0.06 oz•inch) | ||

| |||

FF, REW | 60 – 200 g•cm | ||

(0.83 – 2.78 oz•inch) | |||

|

|

• Tape Tension Measurement

Mode | Tension Meter | Meter Reading | |

Forward | more than 90 g | ||

(more than 3.18 oz) | |||

|

| ||

|

|

| |

Reverse | more than 90 g | ||

(more than 3.18 oz) | |||

|

|

SECTION 5

ELECTRICAL ADJUSTMENTS

TEST MODE

This set have the test mode function. In the test mode, FM Auto Scan/Stop Level and AM (MW) Auto Scan/Stop Level adjustments can be performed easier than it in ordinary procedure.

<Set the Test Mode>

1.Set the “power select” switch (S501) is “A” position.

2.Turn ON the regulated power supply. (All LEDs on the set lights up, and the clock is displayed.)

Note: Press the [OFF] button, if the clock is not displayed.

3.Push the preset [4] button.

4.Push the preset [5] button.

5.Press the preset [1] button for more than two seconds.

6.Then the display indicates all lights, the test mode is set.

<Release the Test mode>

1.Push the [OFF] button.

2.Return the “power select” switch (S501) to initially set posi- tion.

See the adjustment location from on page 16 for the adjustment.

TAPE DECK SECTION

0 dB=0.775 V

0 dB=0.775 V

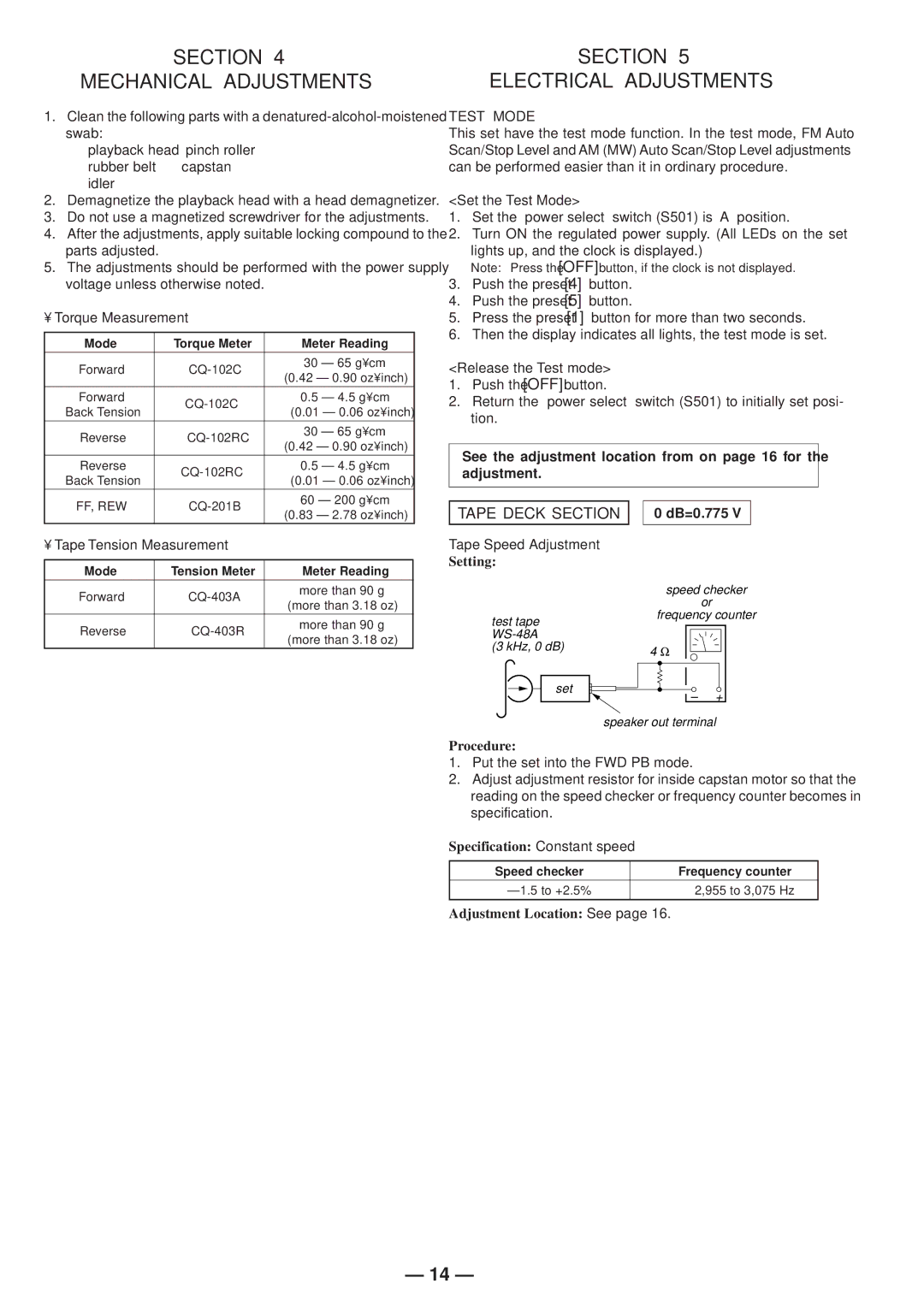

Tape Speed Adjustment

Setting:

|

| speed checker |

|

| or |

test tape |

| frequency counter |

|

| |

|

| |

(3 kHz, 0 dB) | 4 | Ω |

| ||

set |

| – + |

|

|

speaker out terminal

Procedure:

1.Put the set into the FWD PB mode.

2.Adjust adjustment resistor for inside capstan motor so that the reading on the speed checker or frequency counter becomes in specification.

Specification: Constant speed

Speed checker |

| Frequency counter |

| 2,955 to 3,075 Hz | |

|

|

|

Adjustment Location: See page 16. |

| |

– 14 –