MODEL SB1231

12" 4-JAW INDEPENDENT CHUCK

Instruction Sheet

PHONE: (360)

Chucks are heavy! Get assistance when installing or removing the chuck from the lathe. Wear heavy duty leather boots for foot and toe protection, and keep hands and fingers away from all pinch points. Ignoring this warning can lead to a severe crushing injury or finger amputation!

Specifications

• | OD Clamping | ||

• | ID Clamping | ||

• | Chuck Bore Diameter | 2.56" (65mm) | |

• | Chuck Outer Diameter | 11.81" (300mm) | |

• | Maximum Speed | 2500 RPM* | |

• | Mounting Type | ||

• | Construction | ||

• | Chuck Weight | 80 lbs | |

• | Chuck Shipping Weight. | ........................ 85 lbs | |

• | Country of Origin | Taiwan | |

*The maximum speed listed above is ONLY possible with the chuck jaws and the workpiece in complete rotational symmetry. The workpiece weight must be within the limits of the lathe, and the workpiece mass must be of equal density throughout to prevent centrifugal imbalance or radial

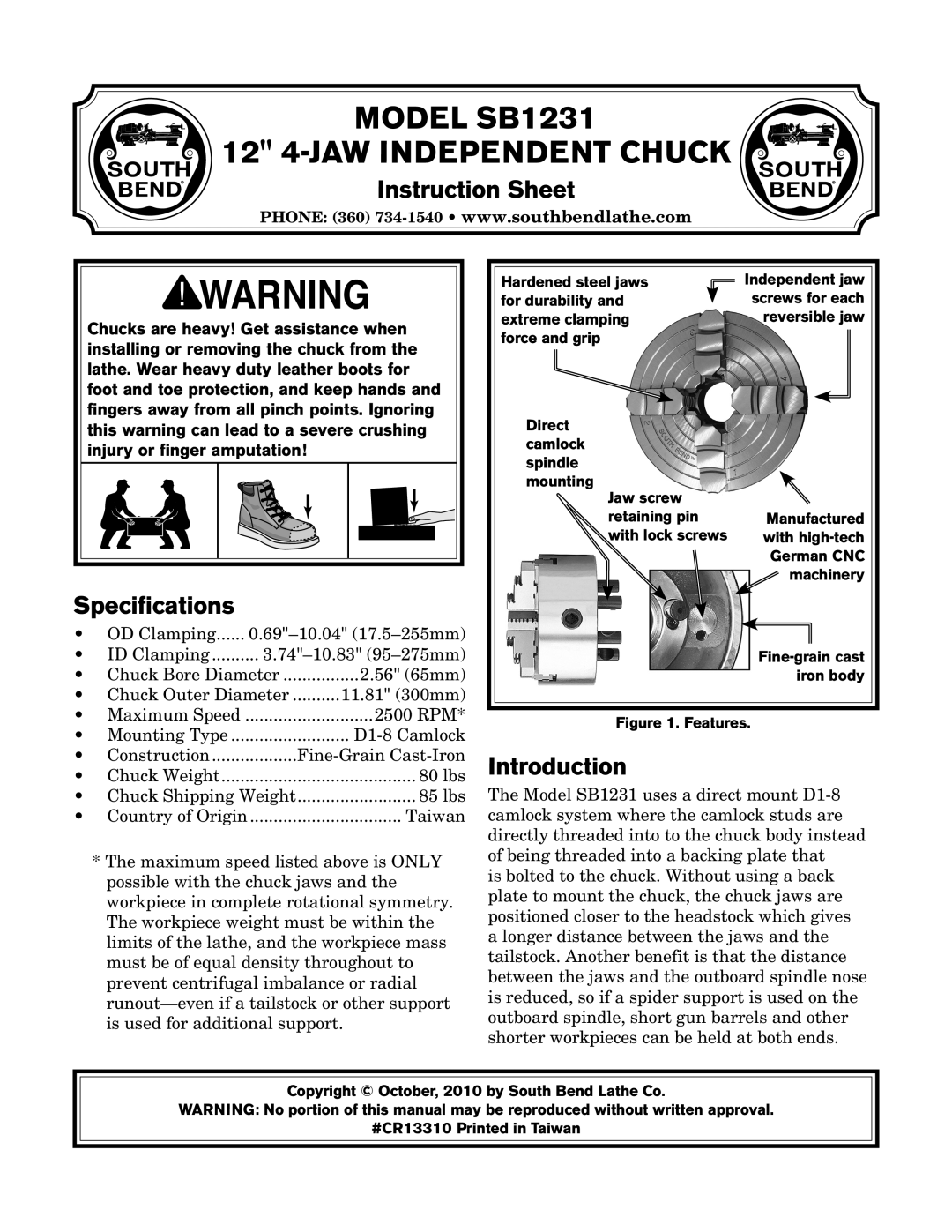

Hardened steel jaws | Independent jaw |

for durability and | screws for each |

extreme clamping | reversible jaw |

force and grip |

|

Direct |

|

camlock |

|

spindle |

|

mounting |

|

Jaw screw |

|

retaining pin | Manufactured |

with lock screws | with |

| German CNC |

| machinery |

| |

| iron body |

Figure 1. Features.

Introduction

The Model SB1231 uses a direct mount

is bolted to the chuck. Without using a back plate to mount the chuck, the chuck jaws are positioned closer to the headstock which gives a longer distance between the jaws and the tailstock. Another benefit is that the distance between the jaws and the outboard spindle nose is reduced, so if a spider support is used on the outboard spindle, short gun barrels and other shorter workpieces can be held at both ends.

Copyright © October, 2010 by South Bend Lathe Co.

WARNING: No portion of this manual may be reproduced without written approval.

#CR13310 Printed in Taiwan