P 2/ 17

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Use for | ||

1R003 | Retaining ring S pliers | Removing Ring springs | ||

|

|

|

|

|

1R005 | Retaining ring R pliers | Removing Retaining ring (INT) round | ||

|

|

|

|

|

1R023 | Pipe ring ( for Arbor press) | When it is difficult to remove Armature from Crank housing complete. | ||

|

|

|

|

|

1R089 | Bearing extractor | When it is difficult to remove Ball bearing 6203LLU. | ||

1R132 | Nose | Attachment for 1R089 to remove Ball bearing 6203LLU | ||

1R139 | Drill chuck extractor |

| ||

|

|

| M8x40 Hex socket head bolt | Removing Crank shaft |

|

|

| ||

|

|

| Flat washer 8 |

|

|

|

|

| |

1R212 | Tip for Retaining ring pliers | Attachment for 1R003 to remove Ring springs | ||

1R214 | Taper sleeve | Fitting Fluoride ring on Impact bolt | ||

1R229 | 1/4” Hex shank bit for M5 | Unscrewing/ screwing M5 size Hex socket head bolt | ||

|

|

|

|

|

1R230 | 1/4” Hex shank bit for M6 | Unscrewing/ screwing M6 size Hex socket head bolt | ||

1R239 | Round bar for Arbor | When it is difficult to remove Armature from Crank housing complete. | ||

1R269 | Bearing extractor | Removing Ball bearing 608DDW from Armature’s commutator end | ||

1R288 | Screwdriver magnetizer | Magnetizing screwdriver when removing Steel balls | ||

1R291 | Retaining ring S and R pliers | Removing Ring spring 34 when disassembling Barrel section | ||

1R306 | Ring spring removing jig | When it is difficult to remove Armature from Crank housing complete. | ||

|

|

|

|

|

1R363 | Ring spring removing tool | Removing Ring spring 25 | ||

|

|

|

|

|

[2] LUBRICATIONS

Apply the following lubricants to the portions to protect the parts and product from unusual abrasion.

Item No. | Description |

| Portion to lubricate |

| Lubricant | Amount | |

1 | Tool holder cap |

| Lip portion |

|

| Makita grease | a little |

7 | Tool retainer |

| Belly portion where Hammer bit contacts | N.No.2 |

| ||

16 | Steel ball 4.8 (4pcs.) | Whole portion |

|

|

|

| |

19 | Fluoride ring 28 |

| The surface where Tool holder contacts |

|

| ||

21 | Impact bolt |

| Cylindrical portion of Striker side |

|

|

| |

22 | Ring 20 |

|

|

|

|

| a little |

23 | Rubber ring 20 |

| Whole portion |

|

|

| |

|

|

|

|

| |||

27 | Flat washer 23 |

|

|

|

| Makita grease |

|

|

|

|

|

|

|

| |

31 | O ring 24 |

| The surface where 32 | Cylinder contacts. | R.No.00 |

| |

32 | Cylinder 32 |

| Inside between Striker and Piston. |

|

| 7g | |

38 | O ring 46 |

|

|

|

|

|

|

49 | Pin 8 |

| Whole portion |

|

|

| a little |

51 | O ring 26 |

|

|

|

|

| |

|

|

|

|

|

| ||

53 | Connecting rod |

| The hole in which Crank shaft’s pin is inserted |

| |||

58 | Crank housing complete Crank room |

|

|

| 20g | ||

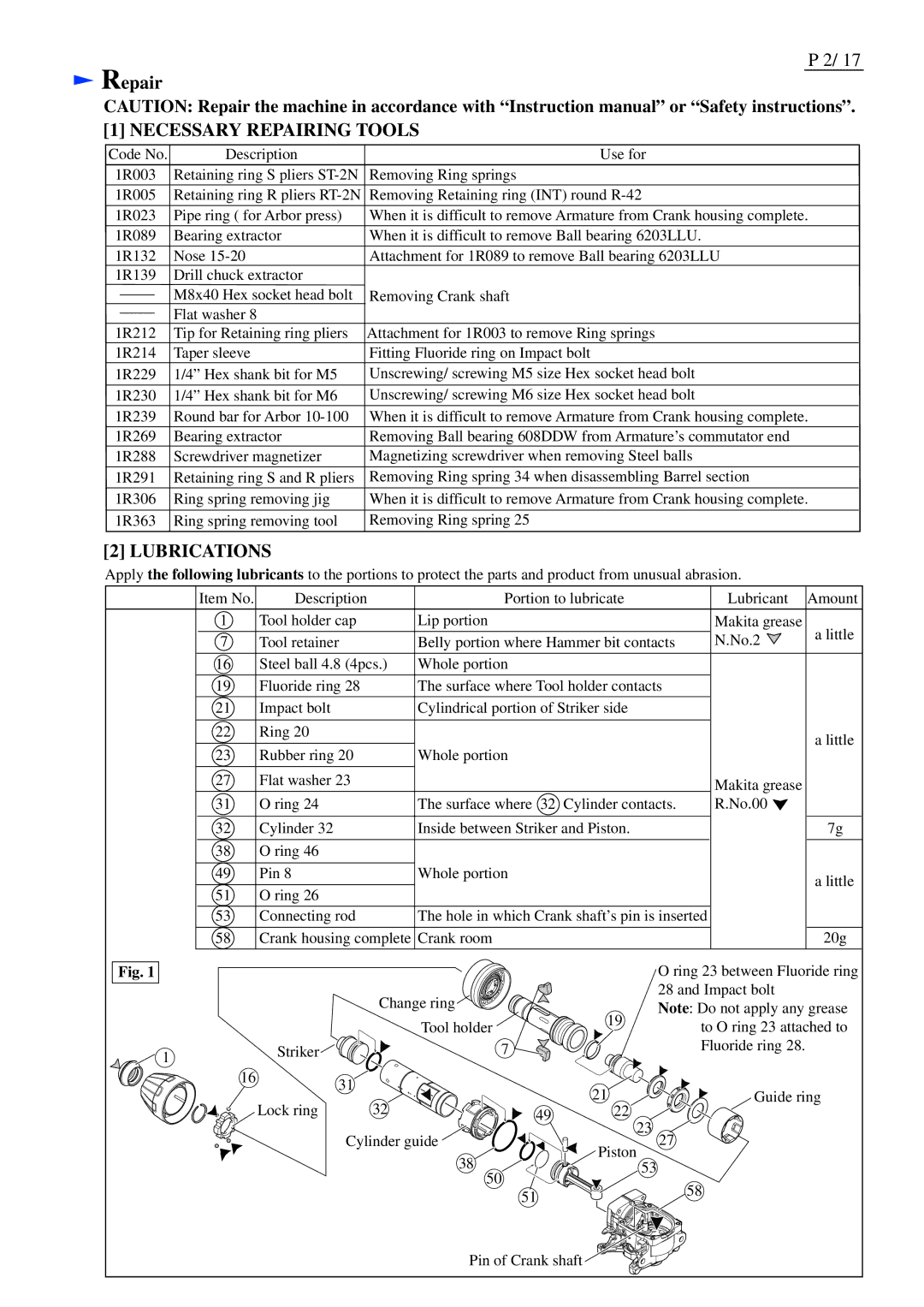

Fig. 1 |

|

|

|

| O ring 23 between Fluoride ring | ||

|

| Change ring |

| 28 and Impact bolt |

| ||

|

|

| Note: Do not apply any grease | ||||

|

|

|

| 19 | |||

|

|

| Tool holder |

| to O ring 23 attached to | ||

|

|

|

|

| |||

1 | Striker |

| 7 |

|

| Fluoride ring 28. |

|

|

|

|

|

|

|

| |

16 | 31 |

|

| 21 |

|

|

|

|

|

|

| Guide ring | |||

| Lock ring | 32 |

|

| |||

| 49 | 22 |

|

|

| ||

| Cylinder guide | 23 | 27 |

|

| ||

|

|

| 38 | Piston |

|

|

|

|

|

| 53 |

|

|

| |

|

|

| 50 |

|

| 58 |

|

|

|

| 51 |

|

|

| |

|

|

|

|

|

|

| |

|

|

| Pin of Crank shaft |

|

|

| |