WARNING

WARNING

Never operate the electrical heating element without being certain the tank is completely filled with water. If any air is left in the top of the tank, the heating element will burn out.

LOCAL CODES

The installation of the tank must be in accordance with these instructions and all applicable local codes and electric utility requirements. In the absence of local codes, install in accordance with the latest edition of the National Electrical Code (NFPA-70).

TEMPERATURE-PRESSURE

RELIEF VALVE

WARNING

WARNING

For protection against excessive pressures and temperatures in this water heater, install temperature-pressure protective equipment required by local codes, but not less than a combination temperature-pressure relief valve certified by a nationally recognized testing laboratory that maintains periodic inspection of production of listed equipment or materials, as meeting the requirements for Relief Valves and Automatic Gas Shut-off Devices for Hot Water Supply Systems, the latest edition of ANSI Z21.22. This valve must be marked with a maximum set pressure not to exceed the marked hydrostatic working pressure of the water heater (150 lbs./sq. in.).

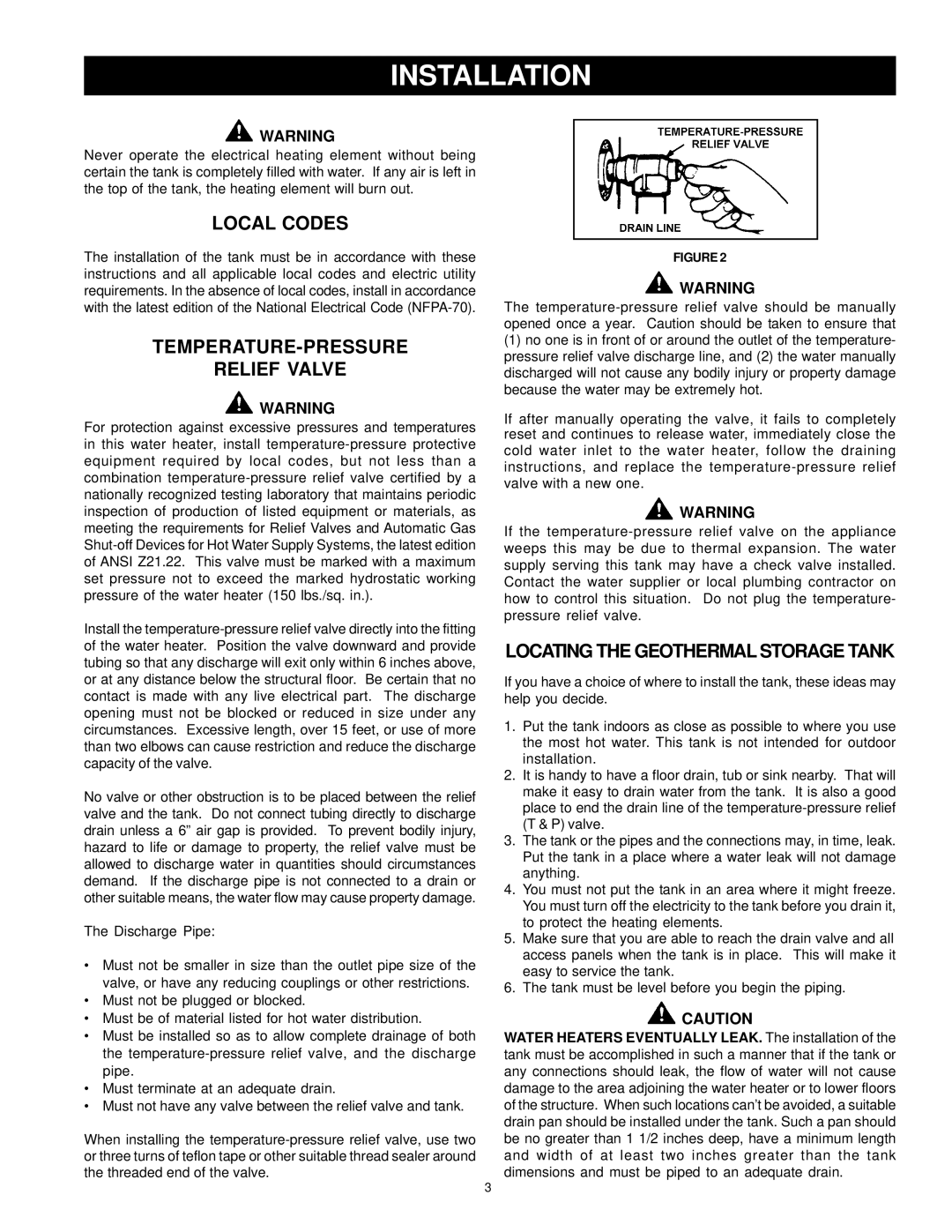

Install the temperature-pressure relief valve directly into the fitting of the water heater. Position the valve downward and provide tubing so that any discharge will exit only within 6 inches above, or at any distance below the structural floor. Be certain that no contact is made with any live electrical part. The discharge opening must not be blocked or reduced in size under any circumstances. Excessive length, over 15 feet, or use of more than two elbows can cause restriction and reduce the discharge capacity of the valve.

No valve or other obstruction is to be placed between the relief valve and the tank. Do not connect tubing directly to discharge drain unless a 6” air gap is provided. To prevent bodily injury, hazard to life or damage to property, the relief valve must be allowed to discharge water in quantities should circumstances demand. If the discharge pipe is not connected to a drain or other suitable means, the water flow may cause property damage.

The Discharge Pipe:

•Must not be smaller in size than the outlet pipe size of the valve, or have any reducing couplings or other restrictions.

•Must not be plugged or blocked.

•Must be of material listed for hot water distribution.

•Must be installed so as to allow complete drainage of both the temperature-pressure relief valve, and the discharge pipe.

•Must terminate at an adequate drain.

•Must not have any valve between the relief valve and tank.

When installing the temperature-pressure relief valve, use two or three turns of teflon tape or other suitable thread sealer around the threaded end of the valve.

FIGURE 2

WARNING

WARNING

The temperature-pressure relief valve should be manually opened once a year. Caution should be taken to ensure that

(1)no one is in front of or around the outlet of the temperature- pressure relief valve discharge line, and (2) the water manually discharged will not cause any bodily injury or property damage because the water may be extremely hot.

If after manually operating the valve, it fails to completely reset and continues to release water, immediately close the cold water inlet to the water heater, follow the draining instructions, and replace the temperature-pressure relief valve with a new one.

WARNING

WARNING

If the temperature-pressure relief valve on the appliance weeps this may be due to thermal expansion. The water supply serving this tank may have a check valve installed. Contact the water supplier or local plumbing contractor on how to control this situation. Do not plug the temperature- pressure relief valve.

LOCATING THE GEOTHERMAL STORAGE TANK

If you have a choice of where to install the tank, these ideas may help you decide.

1.Put the tank indoors as close as possible to where you use the most hot water. This tank is not intended for outdoor installation.

2.It is handy to have a floor drain, tub or sink nearby. That will make it easy to drain water from the tank. It is also a good place to end the drain line of the temperature-pressure relief (T & P) valve.

3.The tank or the pipes and the connections may, in time, leak. Put the tank in a place where a water leak will not damage anything.

4.You must not put the tank in an area where it might freeze. You must turn off the electricity to the tank before you drain it, to protect the heating elements.

5.Make sure that you are able to reach the drain valve and all access panels when the tank is in place. This will make it easy to service the tank.

6.The tank must be level before you begin the piping.

CAUTION

CAUTION

WATER HEATERS EVENTUALLY LEAK. The installation of the tank must be accomplished in such a manner that if the tank or any connections should leak, the flow of water will not cause damage to the area adjoining the water heater or to lower floors of the structure. When such locations can’t be avoided, a suitable drain pan should be installed under the tank. Such a pan should be no greater than 1 1/2 inches deep, have a minimum length and width of at least two inches greater than the tank dimensions and must be piped to an adequate drain.