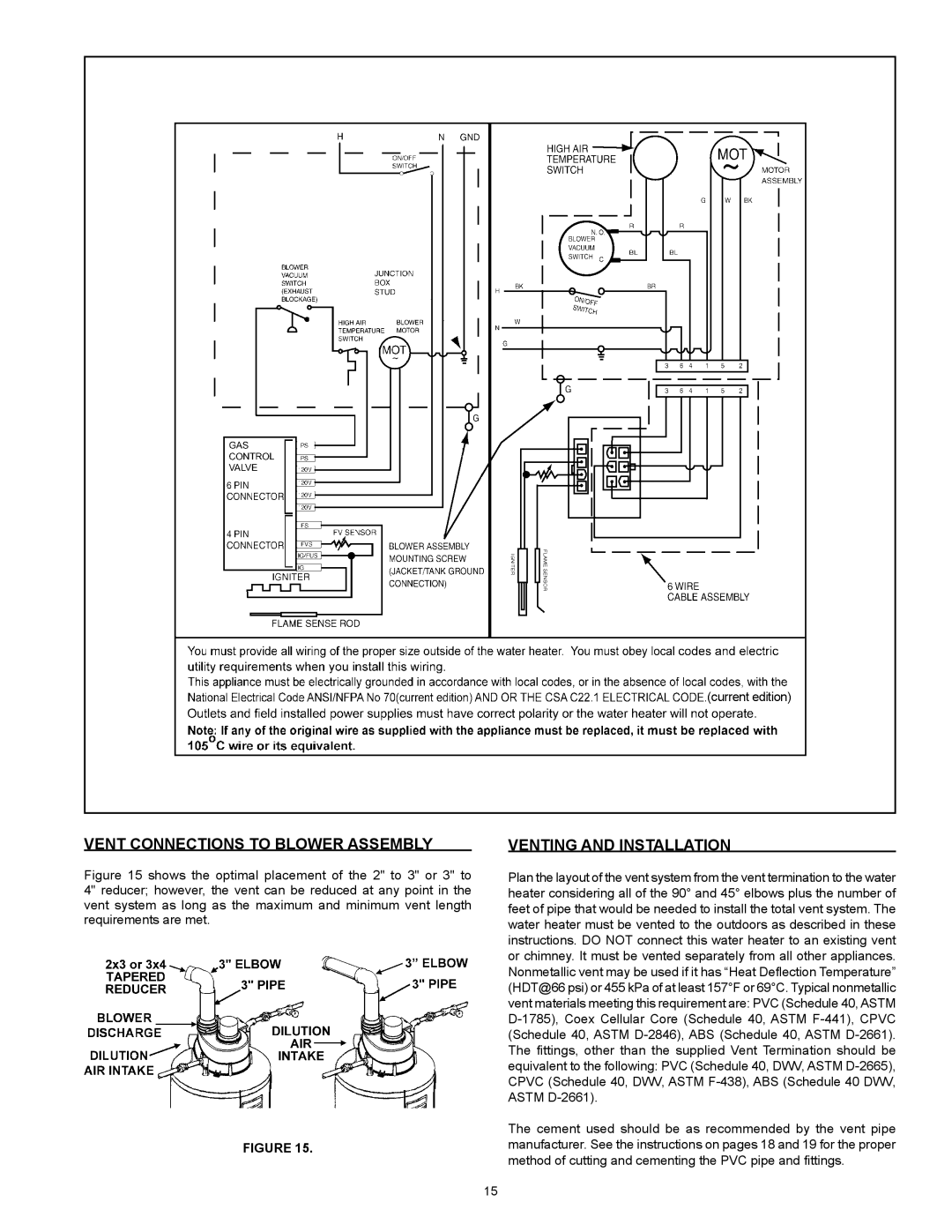

VENT CONNECTIONS TO BLOWER ASSEMBLY

Figure 15 shows the optimal placement of the 2" to 3" or 3" to 4" reducer; however, the vent can be reduced at any point in the vent system as long as the maximum and minimum vent length requirements are met.

FIGURE 15.

VENTING AND INSTALLATION

Plan the layout of the vent system from the vent termination to the water heater considering all of the 90° and 45° elbows plus the number of feet of pipe that would be needed to install the total vent system. The water heater must be vented to the outdoors as described in these instructions. DO NOT connect this water heater to an existing vent or chimney. It must be vented separately from all other appliances. Nonmetallic vent may be used if it has “Heat Deflection Temperature” (HDT@66 psi) or 455 kPa of at least 157°F or 69°C. Typical nonmetallic vent materials meeting this requirement are: PVC (Schedule 40, ASTM

The cement used should be as recommended by the vent pipe manufacturer. See the instructions on pages 18 and 19 for the proper method of cutting and cementing the PVC pipe and fittings.

15