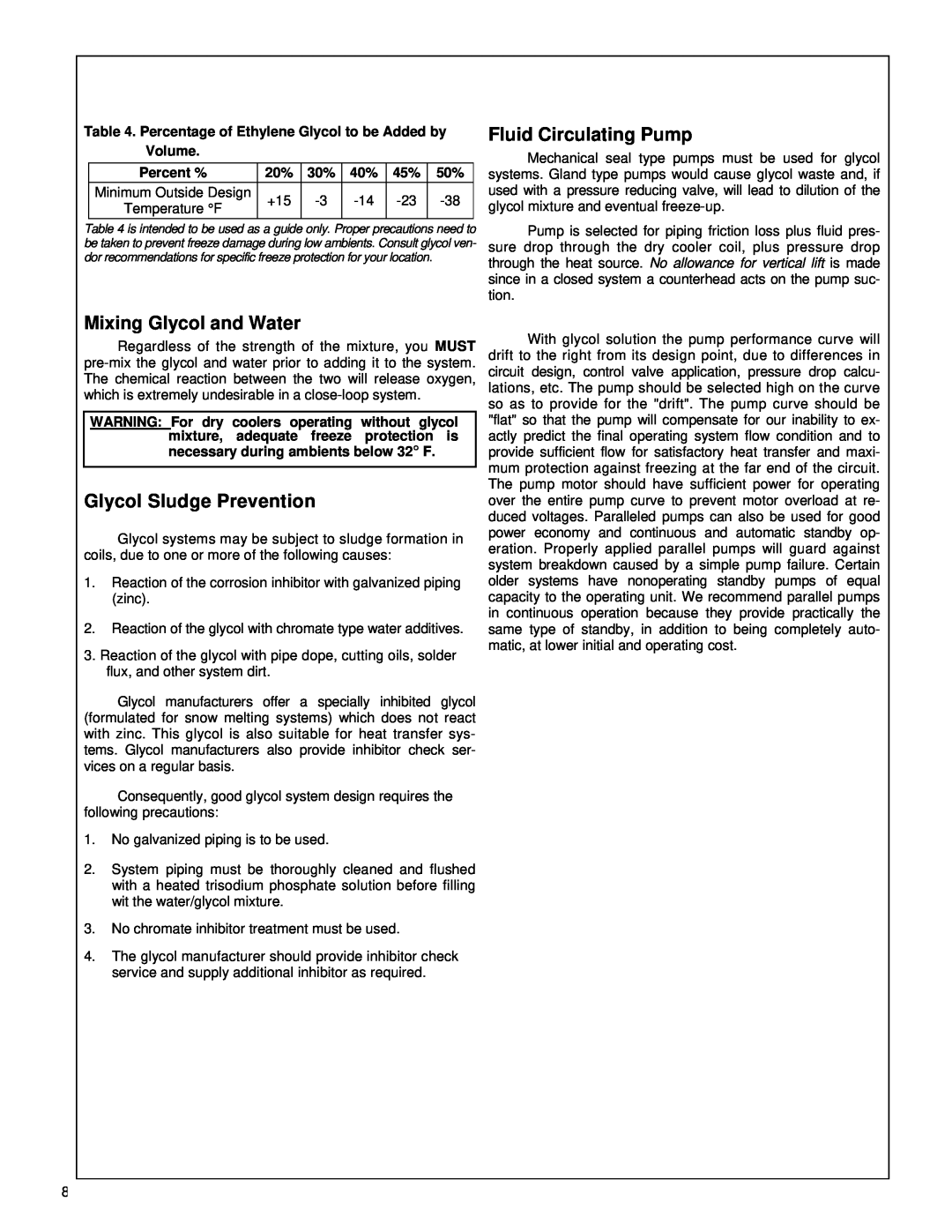

Table 4. Percentage of Ethylene Glycol to be Added by Volume.

Percent % | 20% | 30% | 40% | 45% | 50% | |

Minimum Outside Design | +15 | |||||

Temperature °F | ||||||

|

|

|

|

|

Table 4 is intended to be used as a guide only. Proper precautions need to be taken to prevent freeze damage during low ambients. Consult glycol ven- dor recommendations for specific freeze protection for your location.

Fluid Circulating Pump

Mechanical seal type pumps must be used for glycol systems. Gland type pumps would cause glycol waste and, if used with a pressure reducing valve, will lead to dilution of the glycol mixture and eventual

Pump is selected for piping friction loss plus fluid pres- sure drop through the dry cooler coil, plus pressure drop through the heat source. No allowance for vertical lift is made since in a closed system a counterhead acts on the pump suc- tion.

Mixing Glycol and Water

Regardless of the strength of the mixture, you MUST

WARNING: For dry coolers operating without glycol mixture, adequate freeze protection is necessary during ambients below 32° F.

Glycol Sludge Prevention

Glycol systems may be subject to sludge formation in coils, due to one or more of the following causes:

1.Reaction of the corrosion inhibitor with galvanized piping (zinc).

2.Reaction of the glycol with chromate type water additives.

3.Reaction of the glycol with pipe dope, cutting oils, solder flux, and other system dirt.

Glycol manufacturers offer a specially inhibited glycol (formulated for snow melting systems) which does not react with zinc. This glycol is also suitable for heat transfer sys- tems. Glycol manufacturers also provide inhibitor check ser- vices on a regular basis.

Consequently, good glycol system design requires the following precautions:

1.No galvanized piping is to be used.

2.System piping must be thoroughly cleaned and flushed with a heated trisodium phosphate solution before filling wit the water/glycol mixture.

3.No chromate inhibitor treatment must be used.

4.The glycol manufacturer should provide inhibitor check service and supply additional inhibitor as required.

With glycol solution the pump performance curve will drift to the right from its design point, due to differences in circuit design, control valve application, pressure drop calcu- lations, etc. The pump should be selected high on the curve so as to provide for the "drift". The pump curve should be "flat" so that the pump will compensate for our inability to ex- actly predict the final operating system flow condition and to provide sufficient flow for satisfactory heat transfer and maxi- mum protection against freezing at the far end of the circuit. The pump motor should have sufficient power for operating over the entire pump curve to prevent motor overload at re- duced voltages. Paralleled pumps can also be used for good power economy and continuous and automatic standby op- eration. Properly applied parallel pumps will guard against system breakdown caused by a simple pump failure. Certain older systems have nonoperating standby pumps of equal capacity to the operating unit. We recommend parallel pumps in continuous operation because they provide practically the same type of standby, in addition to being completely auto- matic, at lower initial and operating cost.

8