SDA Series 15-60cfm Compact Dehumidifying Dryers

Unpacking and Inspection

Shipping Information

In the Event of Shipping Damage

If the Shipment is Not Complete

CHAPTER 3 INSTALLATION

Table of Contents

CHAPTER 1 SAFETY

CHAPTER 2: FUNCTIONAL DESCRIPTION

CHAPTER 6 TROUBLESHOOTING

CHAPTER 5 MAINTENANCE

CHAPTER 7 APPENDIX

15, 30, & 60 cfm Compact Dryers

Chapter 1 Safety

1-1How to Use This Manual

Safety Symbols Used in this Manual

1-3Warnings and Precautions

1-2Safety Tag Information

Read Operation and Installation Manual

Dryer Safety Tags

1-4Responsibility

General Responsibility

Operator Responsibility

REMEMBER

Reporting a Safety Defect

Maintenance Responsibility

2-1Models Covered in This Manual

Chapter 2 Functional Description

2-2General Description

What is desiccant?

Figure 1 Typical Dryer Air Flow Schematic

2-3Standard Features

Mechanical Features

Electrical Features

2-5Safety Devices and Interlocks

2-4Options

Controller Features

Safety Circuit Standards

Safety Device Lock-Outs

Fail Safe Operation

Chapter 3 Installation

3-1Uncrating the Equipment

3-2Rigging and Placing the Dryer

POWER ON

15, 30, & 60 cfm Compact Dryers

DEW POINT

3-3Electrical Connections

Three-PhaseModels

3-4Setup Procedures

Checking for Proper Blower Rotation

Floor Mount Models

Installing Water Lines

3-5Initial Start-up

Drying Hopper Air Trap Considerations

Optional Aftercooler

Shutting Down the Dryer

Auto-Tuningthe Dryer

4-1Controller Description and Operation

Chapter 4 Operation

Switches

Indicator Lights

PV SV

Process Air Temperature Controller

Lit when Control Output 1 is on. The Out1

Indicator

Lit when Control Output 2 is on. Not used in

Indicator

Indicator

Setting the Process Air Temperature

Adjustment Level

Indicator

Name

Indicator

Description

Entering Operating Parameters to Select Modes

Setting the High Dew Point Alarm

Process Air Dew Point Display

Optional

Controller Operation

4-2Dryer Operation Procedures

Alarm Display Messages

HEAT COOL 50 SYSTEM NORMAL

HIGH TEMP VALVE MTR

Valve Motor Time-Out Blower Overload No Alarms

PROC BLWR

5-1Preventative Maintenance Schedule

Chapter 5 Maintenance

Every Day

Every week

Figure 9 Air Filter Location and Disassembly

5-2Preventative Maintenance

Servicing Process Air Filters

Vacuuming

Cleaning with Compressed Air

5-3Corrective Maintenance

Symptoms of Worn Desiccant

Servicing the Dew Point Monitor

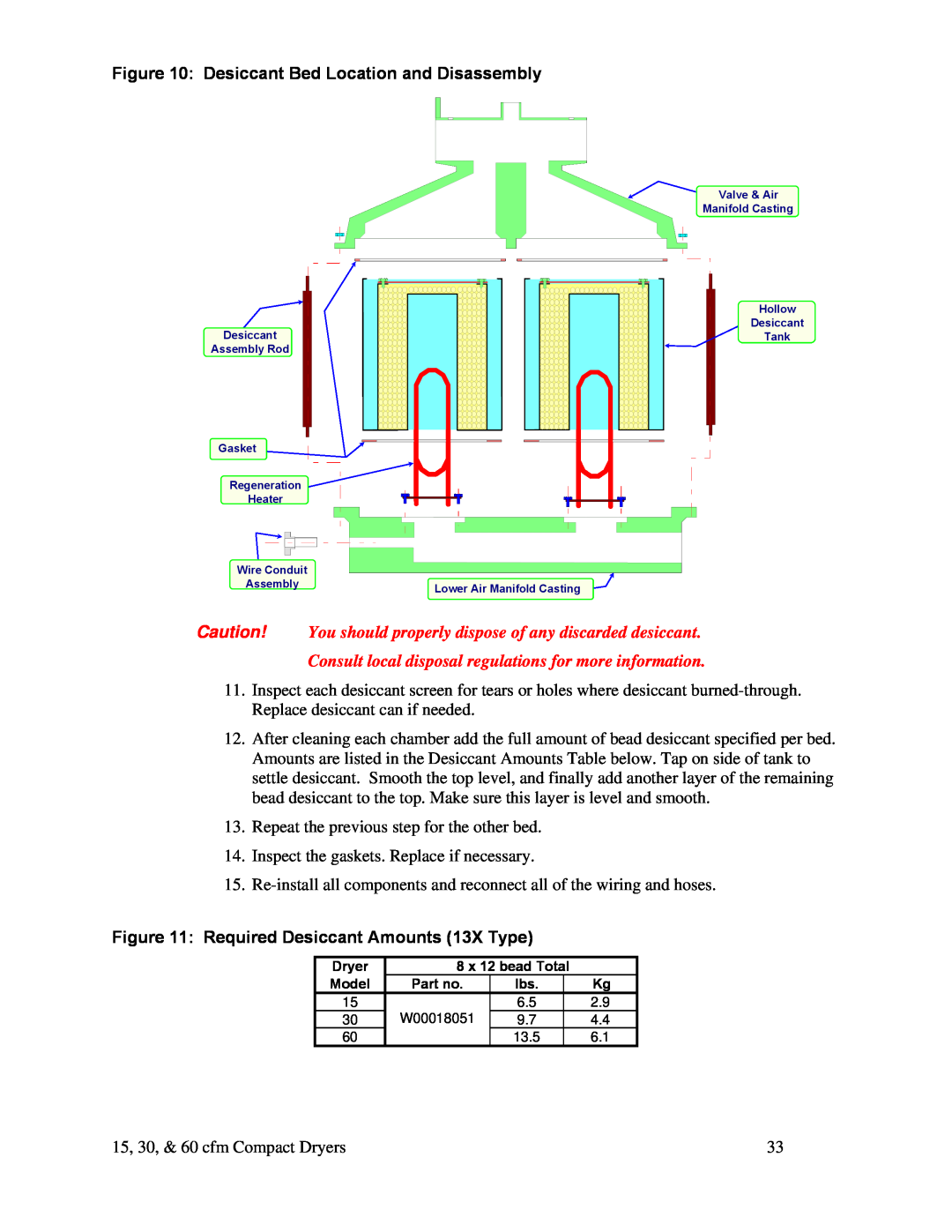

Replacing Worn Desiccant

+ FIRST AID +

Figure 11 Required Desiccant Amounts 13X Type

Figure 10 Desiccant Bed Location and Disassembly

Procedures

Replacing the Process/Regeneration Heater

WARNING! Hazardous electrical current present

Figure 13 Cooling Coil Location and Disassembly

Replacing/Cleaning the Cooling Coil

Replacement Procedures

If used as an after-Cooler 3 to 4 GPM @ 85F

8.Inset the four 10-32bolts back in place

9.Turn the water to the cooling coil back on

15, 30, & 60 cfm Compact Dryers

Chapter 6 Troubleshooting

6-1Introduction

HIGH TEMP

Alarm Message

PROC BLWR

HIGH TEMP

Cause

Using a Thermocouple

VALVE MTR

Alarm Message

Cause

Chapter 7 Appendix

7-1Warranty

Warranty Specifications

Warranty Restrictions

7-2Technical Specifications

Customer Responsibilities

Annex B Information

Aftercooler Design Specifications

7-3Drawings and Diagrams

Regeneration MoistureMake Up Air Exhaust

High Pressure Peripheral Blower

After-Cooler Regeneration MoistureMake Up Air

Figure 16 Low Heat Model 120F to 250F Air Flow

Exhaust

High Pressure Peripheral Blower

DRYER SPARE PARTS LIST 15, 30, 60 cfm Models

7-4Spare Parts List

15, 30, & 60 cfm Compact Dryers

Mechanical Components

HI-COREDESICCANT DRYER 15/30/60 CFM UNITS

15, 30, & 60 cfm Compact Dryers

15, 30, & 60 cfm Compact Dryers

30 CFM

Description

15, 30, & 60 cfm Compact Dryers

60 CFM

Description

A0571672

15, 30, & 60 cfm Compact Dryers

120V CONTROL COMMON PARTS

Description

Credit Returns

7-5Returned Material Policy

7-7Technical Assistance

7-6Dryer Identification Serial Number Tag

Warranty Returns

Service Department

15, 30, & 60 cfm Compact Dryers

Contract Department

![]()