SSV 05/R

4.1. Preparations

Check whether the injector tube is inserted in the material to be conveyed.

Switch on the

Switch on the conveyor unit at the control and maintenance unit.

The conveyor unit should now convey until the conveyor hopper is filled up to the level probe.

4.2. Basic setting of the filling level in the conveyor hopper

The filling level in the conveyor hopper is mainly determined by the level probe.

Filling level too low

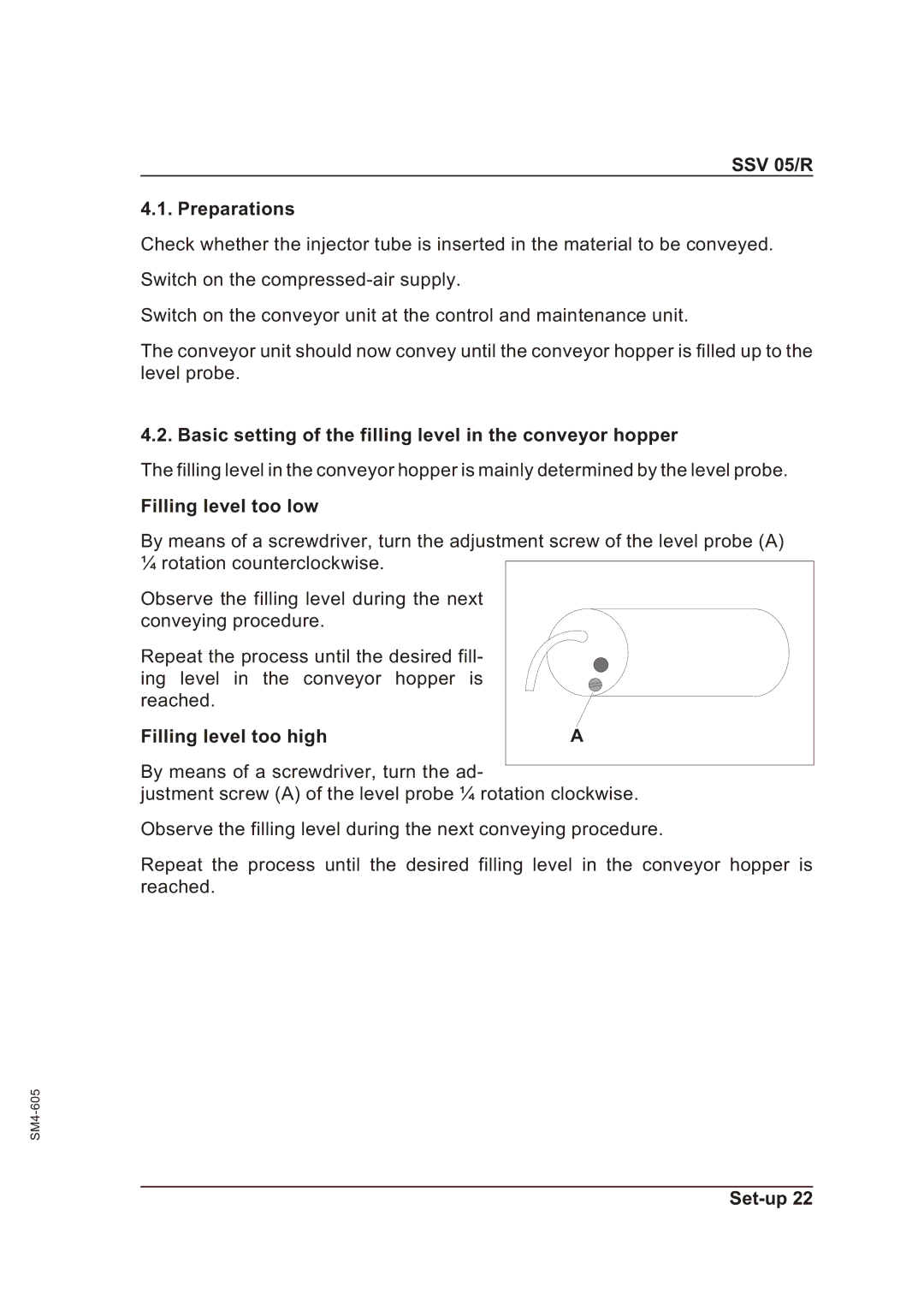

By means of a screwdriver, turn the adjustment screw of the level probe (A) ¼ rotation counterclockwise.

Observe the filling level during the next conveying procedure.

Repeat the process until the desired fill- ing level in the conveyor hopper is reached.

Filling level too high

A

By means of a screwdriver, turn the ad-

justment screw (A) of the level probe ¼ rotation clockwise.

Observe the filling level during the next conveying procedure.

Repeat the process until the desired filling level in the conveyor hopper is reached.