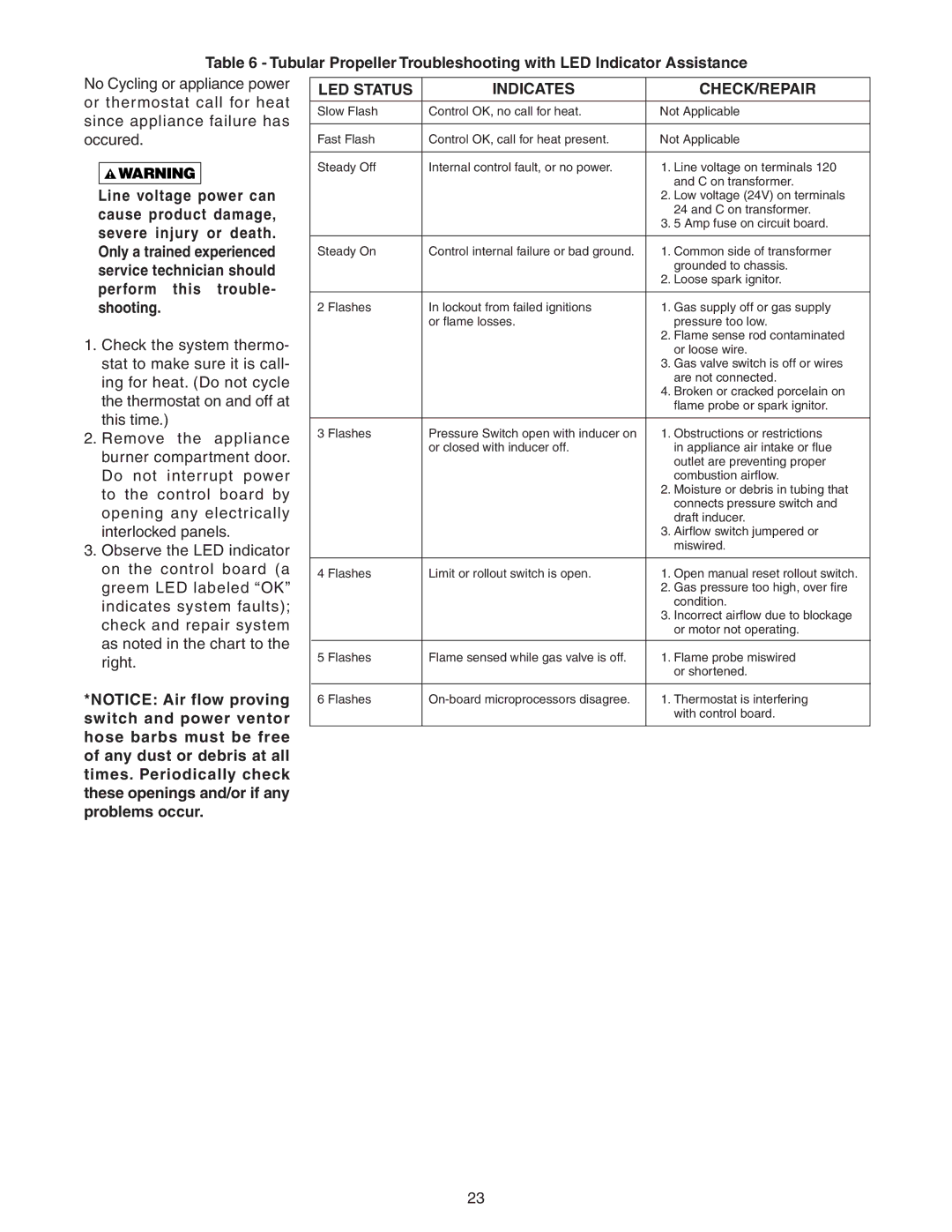

Table 6 - Tubular Propeller Troubleshooting with LED Indicator Assistance

No Cycling or appliance power or thermostat call for heat since appliance failure has occured.

Line voltage power can cause product damage, severe injury or death. Only a trained experienced service technician should perform this trouble- shooting.

1.Check the system thermo- stat to make sure it is call- ing for heat. (Do not cycle the thermostat on and off at this time.)

2.Remove the appliance burner compartment door. Do not interrupt power to the control board by opening any electrically interlocked panels.

3.Observe the LED indicator on the control board (a greem LED labeled “OK” indicates system faults); check and repair system as noted in the chart to the right.

*NOTICE: Air flow proving switch and power ventor hose barbs must be free of any dust or debris at all times. Periodically check these openings and/or if any problems occur.

LED STATUS | INDICATES | CHECK/REPAIR |

|

|

|

Slow Flash | Control OK, no call for heat. | Not Applicable |

|

|

|

Fast Flash | Control OK, call for heat present. | Not Applicable |

|

|

|

Steady Off | Internal control fault, or no power. | 1. Line voltage on terminals 120 |

|

| and C on transformer. |

|

| 2. Low voltage (24V) on terminals |

|

| 24 and C on transformer. |

|

| 3. 5 Amp fuse on circuit board. |

|

|

|

Steady On | Control internal failure or bad ground. | 1. Common side of transformer |

|

| grounded to chassis. |

|

| 2. Loose spark ignitor. |

|

|

|

2 Flashes | In lockout from failed ignitions | 1. Gas supply off or gas supply |

| or flame losses. | pressure too low. |

|

| 2. Flame sense rod contaminated |

|

| or loose wire. |

|

| 3. Gas valve switch is off or wires |

|

| are not connected. |

|

| 4. Broken or cracked porcelain on |

|

| flame probe or spark ignitor. |

|

|

|

3 Flashes | Pressure Switch open with inducer on | 1. Obstructions or restrictions |

| or closed with inducer off. | in appliance air intake or flue |

|

| outlet are preventing proper |

|

| combustion airflow. |

|

| 2. Moisture or debris in tubing that |

|

| connects pressure switch and |

|

| draft inducer. |

|

| 3. Airflow switch jumpered or |

|

| miswired. |

|

|

|

4 Flashes | Limit or rollout switch is open. | 1. Open manual reset rollout switch. |

|

| 2. Gas pressure too high, over fire |

|

| condition. |

|

| 3. Incorrect airflow due to blockage |

|

| or motor not operating. |

|

|

|

5 Flashes | Flame sensed while gas valve is off. | 1. Flame probe miswired |

|

| or shortened. |

|

|

|

6 Flashes | 1. Thermostat is interfering | |

|

| with control board. |

|

|

|

23