GAS PIPING

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() To avoid damage or possible personal injury, do not connect gas piping to this unit until a supply line pressure/leak test has been completed. Connecting the unit before completing the pressure/leak test may damage the unit gas valve and result in a fire hazard.

To avoid damage or possible personal injury, do not connect gas piping to this unit until a supply line pressure/leak test has been completed. Connecting the unit before completing the pressure/leak test may damage the unit gas valve and result in a fire hazard.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Do not rely on a

Do not rely on a

PIPE SIZING

To provide adequate gas pressure to the gas unit heater, size the gas piping as follows:

NOTICE: If more than one unit heater is to be served by the same piping arrangement, the total cu. ft./hr. input and length of pipe must be considered.

1. Find the cu. ft./hr. by using the following formula:

Cu. ft./hr. = Input BTU/Hr. 1000

2.Refer to Table 3. Match “Length of Pipe in Feet” with appropriate “Gas Input - Cu. Ft./Hr.” figure. This figure can then be matched to the pipe size at the top of the column.

Example:

It is determined that a 67 foot (20.4m) run of gas pipe is required to connect a 200 MBTU gas unit heater to a 1,000 BTU/cu ft. (0.29kW) natural gas supply.

200,000 BTU/Hr

1,000 BTU/cu. ft.

Using Table 3, a 1 inch pipe is needed.

NOTE: See General Safety Information section for English/Metric unit conversion factors.

NOTICE: If the gas unit heater is to be fired with LP gas, consult your local LP gas dealer for pipe size information.

NOTICE: HEATER INSTALLATION FOR USE WITH PROPANE (BOTTLED) GAS MUST BE MADE BY A QUALIFIED L.P. GAS DEALER OR INSTALLER. HE/SHE WILL INSURE THAT PROPER JOINT COMPOUNDS ARE USED FOR MAKING PIPE CONNECTIONS; THAT AIR IS PURGED FROM LINES; THAT A THOROUGH TEST IS MADE FOR LEAKS BEFORE OPERATING THE HEATER; AND THAT IT IS PROPERLY CONNECTED TO THE PROPANE GAS SUPPLY SYSTEM.

Before any connection is made to the existing line supplying other gas appliances, contact the local gas company to make sure that the existing line is of adequate size to handle the combined load.

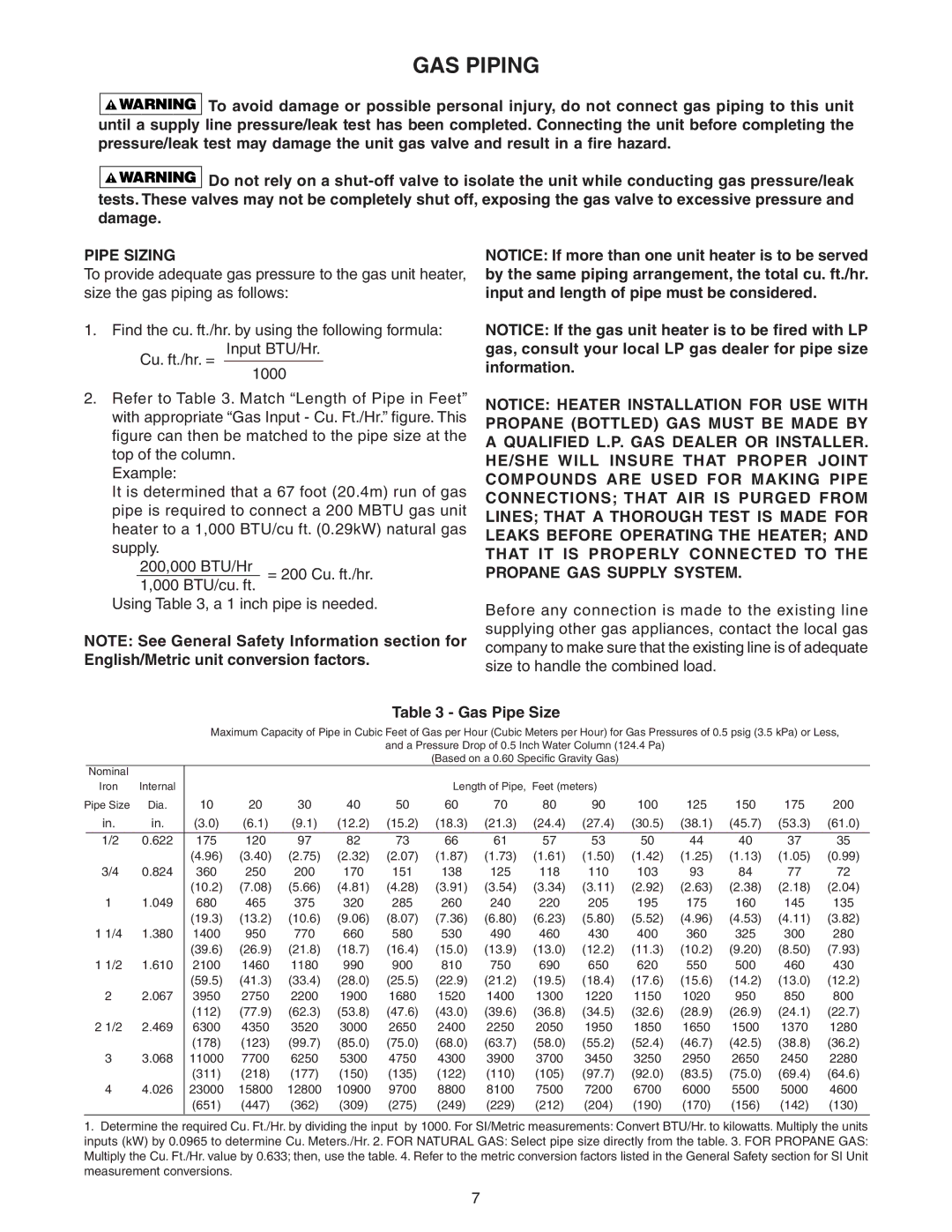

Table 3 - Gas Pipe Size

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour (Cubic Meters per Hour) for Gas Pressures of 0.5 psig (3.5 kPa) or Less,

and a Pressure Drop of 0.5 Inch Water Column (124.4 Pa)

(Based on a 0.60 Specific Gravity Gas)

Nominal

| Iron | Internal |

|

|

|

|

| Length of Pipe, | Feet (meters) |

|

|

|

|

| ||

Pipe Size | Dia. | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | |

| in. | in. | (3.0) | (6.1) | (9.1) | (12.2) | (15.2) | (18.3) | (21.3) | (24.4) | (27.4) | (30.5) | (38.1) | (45.7) | (53.3) | (61.0) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 1/2 | 0.622 | 175 | 120 | 97 | 82 | 73 | 66 | 61 | 57 | 53 | 50 | 44 | 40 | 37 | 35 |

|

|

| (4.96) | (3.40) | (2.75) | (2.32) | (2.07) | (1.87) | (1.73) | (1.61) | (1.50) | (1.42) | (1.25) | (1.13) | (1.05) | (0.99) |

3/4 | 0.824 | 360 | 250 | 200 | 170 | 151 | 138 | 125 | 118 | 110 | 103 | 93 | 84 | 77 | 72 | |

|

|

| (10.2) | (7.08) | (5.66) | (4.81) | (4.28) | (3.91) | (3.54) | (3.34) | (3.11) | (2.92) | (2.63) | (2.38) | (2.18) | (2.04) |

1 | 1.049 | 680 | 465 | 375 | 320 | 285 | 260 | 240 | 220 | 205 | 195 | 175 | 160 | 145 | 135 | |

|

|

| (19.3) | (13.2) | (10.6) | (9.06) | (8.07) | (7.36) | (6.80) | (6.23) | (5.80) | (5.52) | (4.96) | (4.53) | (4.11) | (3.82) |

1 1/4 | 1.380 | 1400 | 950 | 770 | 660 | 580 | 530 | 490 | 460 | 430 | 400 | 360 | 325 | 300 | 280 | |

|

|

| (39.6) | (26.9) | (21.8) | (18.7) | (16.4) | (15.0) | (13.9) | (13.0) | (12.2) | (11.3) | (10.2) | (9.20) | (8.50) | (7.93) |

1 1/2 | 1.610 | 2100 | 1460 | 1180 | 990 | 900 | 810 | 750 | 690 | 650 | 620 | 550 | 500 | 460 | 430 | |

|

|

| (59.5) | (41.3) | (33.4) | (28.0) | (25.5) | (22.9) | (21.2) | (19.5) | (18.4) | (17.6) | (15.6) | (14.2) | (13.0) | (12.2) |

2 | 2.067 | 3950 | 2750 | 2200 | 1900 | 1680 | 1520 | 1400 | 1300 | 1220 | 1150 | 1020 | 950 | 850 | 800 | |

|

|

| (112) | (77.9) | (62.3) | (53.8) | (47.6) | (43.0) | (39.6) | (36.8) | (34.5) | (32.6) | (28.9) | (26.9) | (24.1) | (22.7) |

2 1/2 | 2.469 | 6300 | 4350 | 3520 | 3000 | 2650 | 2400 | 2250 | 2050 | 1950 | 1850 | 1650 | 1500 | 1370 | 1280 | |

|

|

| (178) | (123) | (99.7) | (85.0) | (75.0) | (68.0) | (63.7) | (58.0) | (55.2) | (52.4) | (46.7) | (42.5) | (38.8) | (36.2) |

3 | 3.068 | 11000 | 7700 | 6250 | 5300 | 4750 | 4300 | 3900 | 3700 | 3450 | 3250 | 2950 | 2650 | 2450 | 2280 | |

|

|

| (311) | (218) | (177) | (150) | (135) | (122) | (110) | (105) | (97.7) | (92.0) | (83.5) | (75.0) | (69.4) | (64.6) |

4 | 4.026 | 23000 | 15800 | 12800 | 10900 | 9700 | 8800 | 8100 | 7500 | 7200 | 6700 | 6000 | 5500 | 5000 | 4600 | |

|

|

| (651) | (447) | (362) | (309) | (275) | (249) | (229) | (212) | (204) | (190) | (170) | (156) | (142) | (130) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.Determine the required Cu. Ft./Hr. by dividing the input by 1000. For SI/Metric measurements: Convert BTU/Hr. to kilowatts. Multiply the units inputs (kW) by 0.0965 to determine Cu. Meters./Hr. 2. FOR NATURAL GAS: Select pipe size directly from the table. 3. FOR PROPANE GAS: Multiply the Cu. Ft./Hr. value by 0.633; then, use the table. 4. Refer to the metric conversion factors listed in the General Safety section for SI Unit measurement conversions.

7