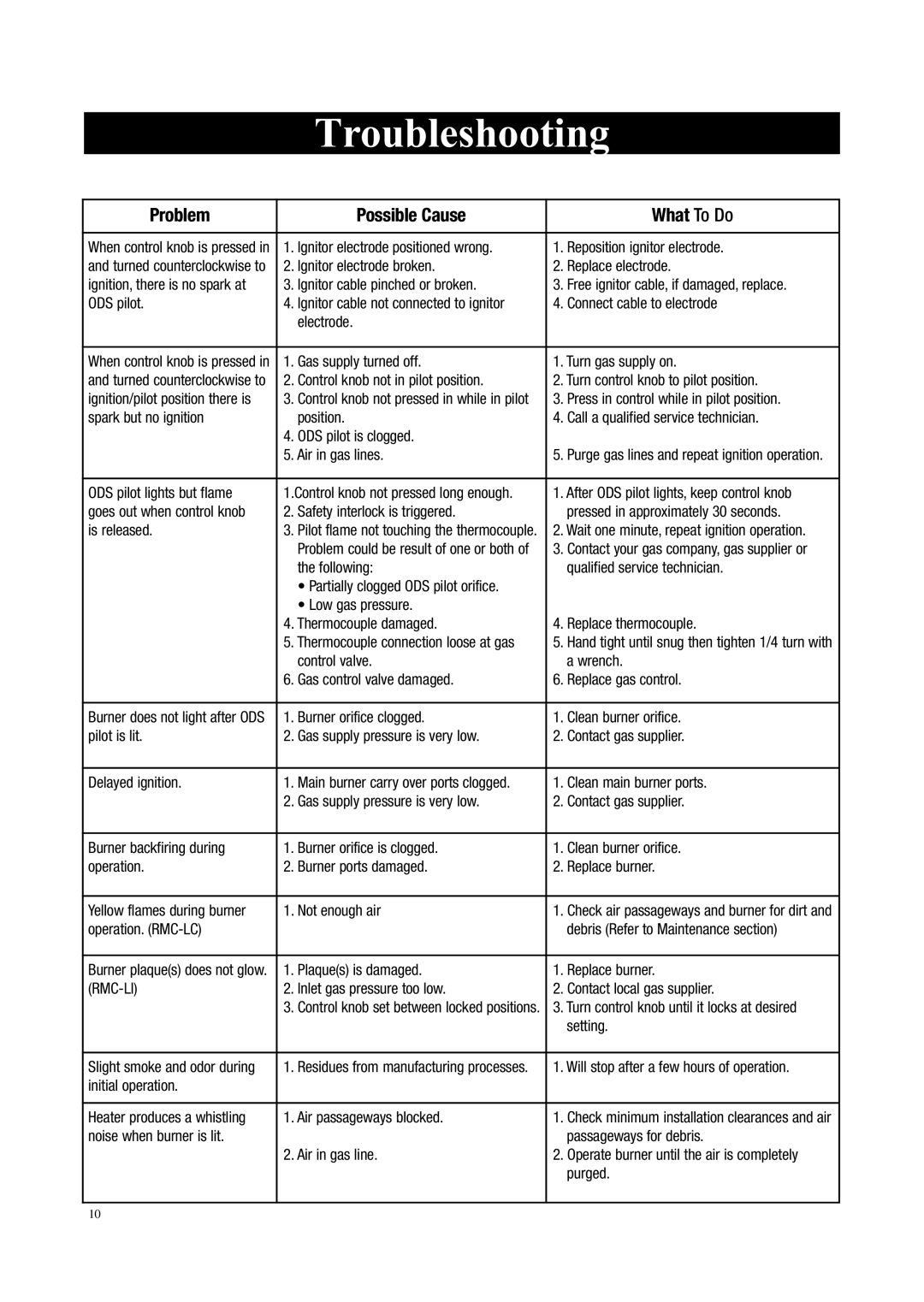

Problem |

| Possible Cause |

| What To Do |

|

|

|

|

|

When control knob is pressed in | 1. | Ignitor electrode positioned wrong. | 1. | Reposition ignitor electrode. |

and turned counterclockwise to | 2. | Ignitor electrode broken. | 2. | Replace electrode. |

ignition, there is no spark at | 3. | Ignitor cable pinched or broken. | 3. | Free ignitor cable, if damaged, replace. |

ODS pilot. | 4. | Ignitor cable not connected to ignitor | 4. | Connect cable to electrode |

|

| electrode. |

|

|

|

|

|

| |

When control knob is pressed in | 1. | Gas supply turned off. | 1. Turn gas supply on. | |

and turned counterclockwise to | 2. | Control knob not in pilot position. | 2. Turn control knob to pilot position. | |

ignition/pilot position there is | 3. | Control knob not pressed in while in pilot | 3. | Press in control while in pilot position. |

spark but no ignition |

| position. | 4. | Call a qualified service technician. |

| 4. | ODS pilot is clogged. |

|

|

| 5. Air in gas lines. | 5. | Purge gas lines and repeat ignition operation. | |

|

|

| ||

ODS pilot lights but flame | 1.Control knob not pressed long enough. | 1. After ODS pilot lights, keep control knob | ||

goes out when control knob | 2. | Safety interlock is triggered. |

| pressed in approximately 30 seconds. |

is released. | 3. | Pilot flame not touching the thermocouple. | 2. Wait one minute, repeat ignition operation. | |

|

| Problem could be result of one or both of | 3. | Contact your gas company, gas supplier or |

|

| the following: |

| qualified service technician. |

|

| • Partially clogged ODS pilot orifice. |

|

|

|

| • Low gas pressure. |

|

|

| 4. Thermocouple damaged. | 4. | Replace thermocouple. | |

| 5. Thermocouple connection loose at gas | 5. | Hand tight until snug then tighten 1/4 turn with | |

|

| control valve. |

| a wrench. |

| 6. | Gas control valve damaged. | 6. | Replace gas control. |

|

|

|

|

|

Burner does not light after ODS | 1. | Burner orifice clogged. | 1. | Clean burner orifice. |

pilot is lit. | 2. | Gas supply pressure is very low. | 2. | Contact gas supplier. |

|

|

|

|

|

Delayed ignition. | 1. | Main burner carry over ports clogged. | 1. | Clean main burner ports. |

| 2. | Gas supply pressure is very low. | 2. | Contact gas supplier. |

|

|

|

|

|

Burner backfiring during | 1. | Burner orifice is clogged. | 1. | Clean burner orifice. |

operation. | 2. | Burner ports damaged. | 2. | Replace burner. |

|

|

|

|

|

Yellow flames during burner | 1. | Not enough air | 1. | Check air passageways and burner for dirt and |

operation. |

|

|

| debris (Refer to Maintenance section) |

|

|

|

|

|

Burner plaque(s) does not glow. | 1. | Plaque(s) is damaged. | 1. | Replace burner. |

| 2. | Inlet gas pressure too low. | 2. | Contact local gas supplier. |

| 3. | Control knob set between locked positions. | 3. Turn control knob until it locks at desired | |

|

|

|

| setting. |

|

|

|

| |

Slight smoke and odor during | 1. | Residues from manufacturing processes. | 1. Will stop after a few hours of operation. | |

initial operation. |

|

|

|

|

|

|

|

| |

Heater produces a whistling | 1. Air passageways blocked. | 1. | Check minimum installation clearances and air | |

noise when burner is lit. |

|

|

| passageways for debris. |

| 2. Air in gas line. | 2. | Operate burner until the air is completely | |

|

|

|

| purged. |

|

|

|

|

|

10