Model MS-63

Proposition 65WARNING

Stow MS-63 Mixer Operation and Parts Manual REV. #5 03/26/10

Stow MS-63 PLASTER/MORTAR Mixer Table of Contents

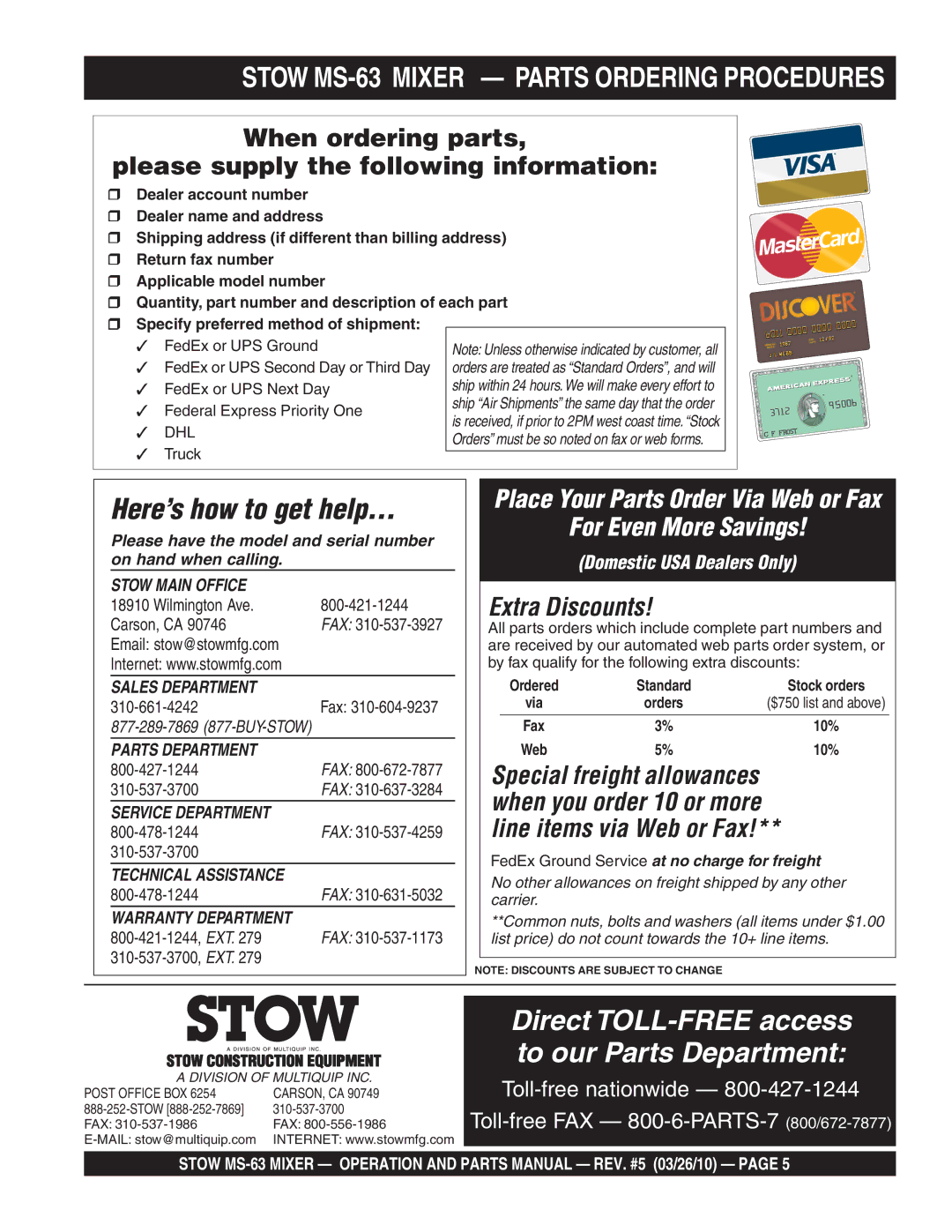

Direct TOLL-FREE access to our Parts Department

Specifications Engine & Electric Motor

Stow MS-63 PLASTER/MORTAR Mixer Specifications

Dimensions

Stow MS-63 PLASTER/MORTAR Mixer Dimensions

Respiratory Hazards

Stow MS-63 Mixer Safety Message Alert Symbols

Burn Hazards

Equipment Damage

Stow MS-63 Mixer Safety Message Alert Symbols

Accidental Starting Hazards

Eye and Hearing Hazards

Read this manual

Stow MS-63 PLASTER/MORTAR Mixer Rules for Safe Operation

Stand Clear

Mixer when in use

Stow MS-63 PLASTER/MORTAR Mixer -TOWING Guidelines

Towing Safety Precautions Regularly Inspect

Tow Bar toVehicle Connection Coupler Only

Replacing

When Towing

Stow MS-63 PLASTER/MORTAR Mixer Safety Chain Connection

Always Tow with

Tow Bar to Mixer Connection

Machine Safety Decals

MS-63 PLASTER/MORTAR Mixer Operation and Safety Decals

Stow MS-63 PLASTER/MORTAR Mixer General Information

Engine Maintenance

Mixer Components

Stow MS-63 PLASTER/MORTAR Mixer Basic Mixer Components

Burn Hazard

Stow MS-63 PLASTER/MORTAR Mixer Basic Engine Components

Fuel Hazard

Electric Motor Connection

Stow MS-63 PLASTER/MORTAR Mixer Electric Motor

Electric Motor

Electric MotorVoltage Switch

Stow MS-63 Paddle Blade Adjustment Steel Drum

Before Starting

Stow MS-63 PLASTER/MORTAR Mixer Inspection

Inspection

Engine Oil Check

Stow MS-63 PLASTER/MORTAR Mixer Inspection

Respiratory Hazard

Stow MS-63 PLASTER/MORTAR Mixer START-UP Procedures

General Safety

Engine ON/OFF Switch

MS-63 PLASTER/MORTAR Mixer START-UP Procedures

Stow MS-63 PLASTER/MORTAR Mixer OPERATION/SHUT-DOWN

Dump Handle Safety

Engine Maintenance Schedule

Stow MS-63 PLASTER/MORTAR Mixer Maintenance Engine

Hazard

Stow MS-63 PLASTER/MORTAR Mixer Maintenance Engine

Stow MS-63 PLASTER/MORTAR Mixer Maintenance Mixer

Main Gear and Drive Pinion Alignment

Stow MS-63 PLASTER/MORTAR Mixer Maintenance Mixer

DamagedWheels

Tires/Wheels/Lug Nuts

Tires Wear/Inflation

Eyesight Hazard

Start all wheel lug nuts by hand

Lug Nut Torque Requirements

Suspension

Mixer Cleaning

Keep Hands

Mixer Storage

Engine Troubleshooting

Stow MS-63 PLASTER/MORTAR Mixer -TROUBLESHOOTING Engine

White

Mixer Troubleshooting

Stow MS-63 -TROUBLESHOOTING MIXER/ELECTRIC Motor

Electric Motor Wiring Diagram

Stow MS-63 Mixer -WIRING Diagram Electric Motor

Stow MS-63 Mixer Operation and Parts Manual REV. #5 03/26/10

QTY. Column

Explanation of Code in Remarks Column

NO. Column

Part NO. Column

GX240K1HA2 Engines

Stow MS-63 Mixer Suggested Spare Parts

Nameplate and Decals

DECAL, Warning Safety Grate

DECAL, Safety Instructions

See Operation and Safety Decals

DECAL, Towing Instructions

Frame Assy

Stow MS-63 Mixer Frame Assy

Stow MS-63 Mixer Frame Assy

Paddle Shaft Assy

Paddle ARM, Center Engine END

Paddle Shaft

INSERT, Paddle ARM

Paddle ARM, Engine END

Steel Drum Assy

Stow MS-63 Mixer Steel Drum Assy

Stow MS-63 Mixer Steel Drum Assy

Drum and Paddle Shaft Complete Assy

Stow MS-63 Mixer Drum & Paddle Shaft Complete Assy

CAP, Grease Fitting

Bearing Sealed

WASHER, Flat 5/16

WASHER, Lock 5/15

Axle Assy

LUG Nuts

Dust CAP

Castle NUT

WASHER, FLAT, .087 Thickness

Engine Assy

Pillow Block Bearing

Flat Washer 3/8

RING, Retainer

Pinion Gear

Stow MS-63 Mixer Electric Motor Assy

PULLEY, Small

Electric Motor 1.5 HP

Cabinet Assy

Wire Harness

SWITCH, PUSH-PULL

Includes Items W

Rubber Protector

AIR Cleaner Assy

Gasket Elbow

Camshaft Assy

ROD, Push

Carburetor Assy

Gasket SET

Control Assy

ARM, Governor

Crankcase Cover Assy

Honda GX160K1QMX2HX2 Engine Crankcase Cover Assy

GASKET, OIL Filler CAP

Crankshaft Assy

Crankshaft H- Type

Cylinder Barrel Assy

Honda GX160K1QMX2HX2 Engine Cylinder Barrel Assy

Cylinder Head Assy

GUIDE, IN. Valve Over Size

FAN Cover Assy

PLATE, Side STD

Flywheel Assy

FAN, Cooling

Muffler Assy

Muffler Comp

Fuel Tank Assy

RUBBER, Supporter

Ignition Coil Assy

Coil ASSY., Ignition

Piston Assy

Ring SET, Piston STD

Recoil Starter Assy

Honda GX160K1QMX2HX2 Engine Recoil Starter Assy

Gear Reduction Assy

GASKET, Reduction Case

CASE, Reduction

COVER, Reduction

SHAFT, P.T.O

Label Assy

Assy

Honda GX240K1HA2 Engine AIR Cleaner Assy

COVER, AIR Cleaner

ELEMENT, AIR CLEANER, Dual

GROMMET, AIR Cleaner

COLLAR, AIR Cleaner

Honda GX240K1HA2 Engine Camshaft Assy

Camshaft

SPRING, Weight Return

ROD Push

ARM Valve Rocker

Honda GX240K1HA2 Engine Carburetor Assy

Gasket SET

PLATE, Lever Setting

Valve SET, Float

Float SET

Honda GX240K1HA2 Engine Control Assy

ROD, Governor

ARM, Governor

SPRING, Governor

SPRING, Throttle Return

Honda GX240K1HA2 Engine Crankcase Cover Assy

HOLDER, Governor Weight

WEIGHT, Governor

PIN, Governor Weight

Type Balancer

Honda GX240K1HA2ENGINE Crankshaft Assy

Weight Balancer

Honda GX240K1HA2 Engine Cylinder Barrel Assy

SHAFT, Governor ARM

Switch ASSY., OIL Level

Ring 14MM Arai

NUT Flange 10MM

Honda GX240K1HA2 Engine Cylinder Head Assy

GUIDE, EX. VALVE, OS, Optional

GUIDE, VALVE, OS, Optional

CLIP, Valve Guide

GASKET, Cylinder Head

Honda GX240K1HA2 Engine FAN Cover Assy

CLIP, Wire Harness

Switch ASSY., Engine Stop

CLIP, Tube

Shroud

Honda GX240K1HA2 Engine Flywheel Assy

Flywheel Comp

FAN, Cooling

NUT, Special 16MM

KEY, Special Woodruff

Honda GX240K1HA2 Engine Muffler Assy

PROTECTOR, Muffler

Muffler

PROTECTOR, EX. Pipe

PIPE, EX

Honda GX240K1HA2 Engine Fueltank Assy

JOINT, Fuel Tank

Rubber Supporter 107MM

Tank COMP., Fuel *NH1*, Black

GASKET, Fuel Filler CAP

Honda GX240K1HA2ENGINE Ignition Assy

WIRE, Stop Switch 370MM

GROMMET, Wire

Coil ASSY., Ignition

CAP ASSY., Noise Suppressor

Honda GX240K1HA2 Engine Piston Assy

Ring SET, PISTON, STD

BOLT, Connecting ROD

Ring SET, PISTON, 0.75, Optional

PISTON, Standard

Honda GX240K1HA2 Engine Recoil Starter Assy

RATCHET, Starter

PULLEY, Recoil Starter

SPRING, Friction

SPRING, Starter Return

Honda GX240K1HA2 Engine Gear Reduction Assy

Countershaft

GEAR, Primary Drive 17T

SHAFT, P.T.O. H- Type

Shim a Optional

Honda GX240K1HA2 Engine Label Assy

EMBLEM, Internal

Labels Assy

MARK, CAUTION, External

LABEL, Caution

Terms And Conditions Of Sale Stow Construction Equipment

Stow MS-63 Mixer Operation and Parts Manual REV. #5 03/26/10

HERE’S HOW to GET Help