30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| I | X | . |

| S | e | t | - | U | p |

|

| & |

| A | d | j | u | s | t | m | e | n | t |

|

I X . S e t - U p & A d j u s t m e n t | 31 |

The more you move your rear wheels forward, the more likely your chair will tip over back- wards. Always make adjustment in small incre- ments, and check the stability of your chair with a spotter to prevent

NOTE– Adjusting your chair’s center of gravity will require

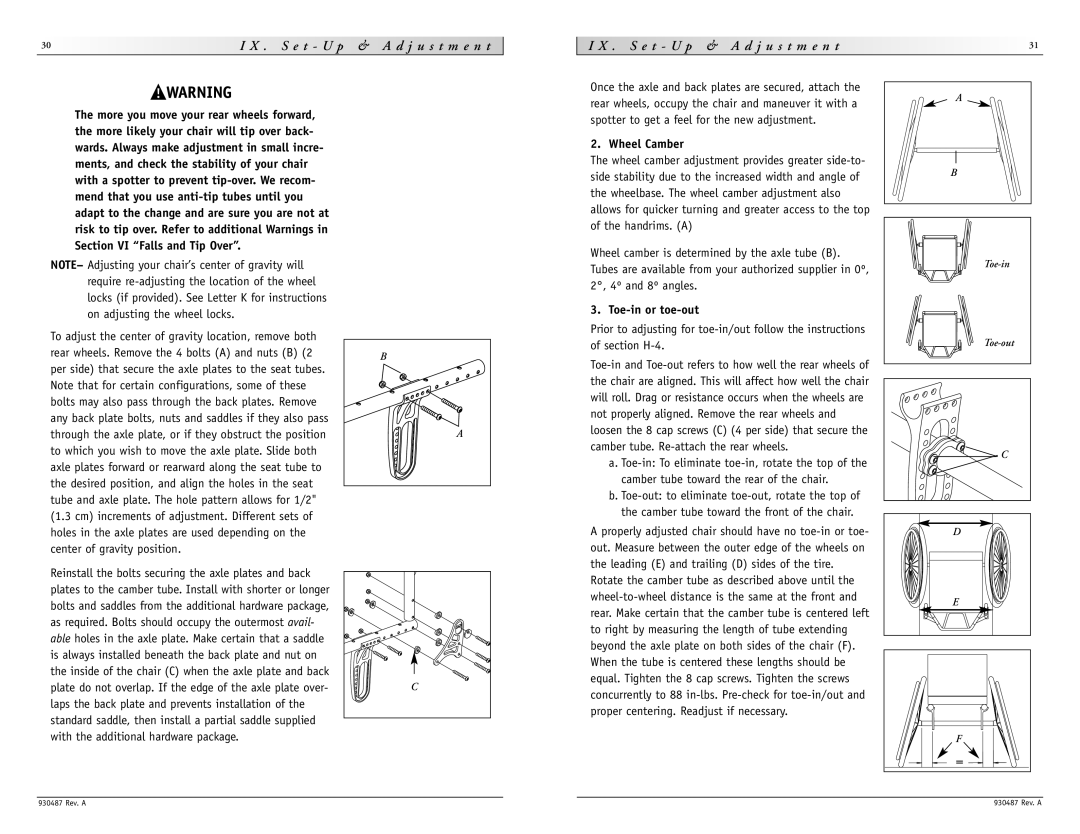

To adjust the center of gravity location, remove both rear wheels. Remove the 4 bolts (A) and nuts (B) (2 per side) that secure the axle plates to the seat tubes. Note that for certain configurations, some of these bolts may also pass through the back plates. Remove any back plate bolts, nuts and saddles if they also pass through the axle plate, or if they obstruct the position to which you wish to move the axle plate. Slide both axle plates forward or rearward along the seat tube to the desired position, and align the holes in the seat tube and axle plate. The hole pattern allows for 1/2" (1.3 cm) increments of adjustment. Different sets of holes in the axle plates are used depending on the center of gravity position.

B |

A |

Once the axle and back plates are secured, attach the | A | |

rear wheels, occupy the chair and maneuver it with a | ||

| ||

spotter to get a feel for the new adjustment. |

| |

2. Wheel Camber |

| |

The wheel camber adjustment provides greater | B | |

side stability due to the increased width and angle of | ||

the wheelbase. The wheel camber adjustment also |

| |

allows for quicker turning and greater access to the top |

| |

of the handrims. (A) |

|

Wheel camber is determined by the axle tube (B). | ||

Tubes are available from your authorized supplier in 0º, | ||

| ||

2°, 4º and 8º angles. |

| |

3. |

| |

Prior to adjusting for |

| |

of section |

| ||

the chair are aligned. This will affect how well the chair |

| |

will roll. Drag or resistance occurs when the wheels are |

| |

not properly aligned. Remove the rear wheels and |

| |

loosen the 8 cap screws (C) (4 per side) that secure the |

| |

camber tube. | C | |

a. | ||

| ||

camber tube toward the rear of the chair. |

| |

b. |

| |

the camber tube toward the front of the chair. |

| |

A properly adjusted chair should have no | D | |

out. Measure between the outer edge of the wheels on |

| |

the leading (E) and trailing (D) sides of the tire. |

|

Reinstall the bolts securing the axle plates and back plates to the camber tube. Install with shorter or longer bolts and saddles from the additional hardware package, as required. Bolts should occupy the outermost avail- able holes in the axle plate. Make certain that a saddle is always installed beneath the back plate and nut on the inside of the chair (C) when the axle plate and back plate do not overlap. If the edge of the axle plate over- laps the back plate and prevents installation of the standard saddle, then install a partial saddle supplied with the additional hardware package.

C |

Rotate the camber tube as described above until the |

| |

E | ||

rear. Make certain that the camber tube is centered left | ||

| ||

to right by measuring the length of tube extending |

| |

beyond the axle plate on both sides of the chair (F). |

| |

When the tube is centered these lengths should be |

| |

equal. Tighten the 8 cap screws. Tighten the screws |

| |

concurrently to 88 |

| |

proper centering. Readjust if necessary. |

| |

| F |

930487 Rev. A

930487 Rev. A |