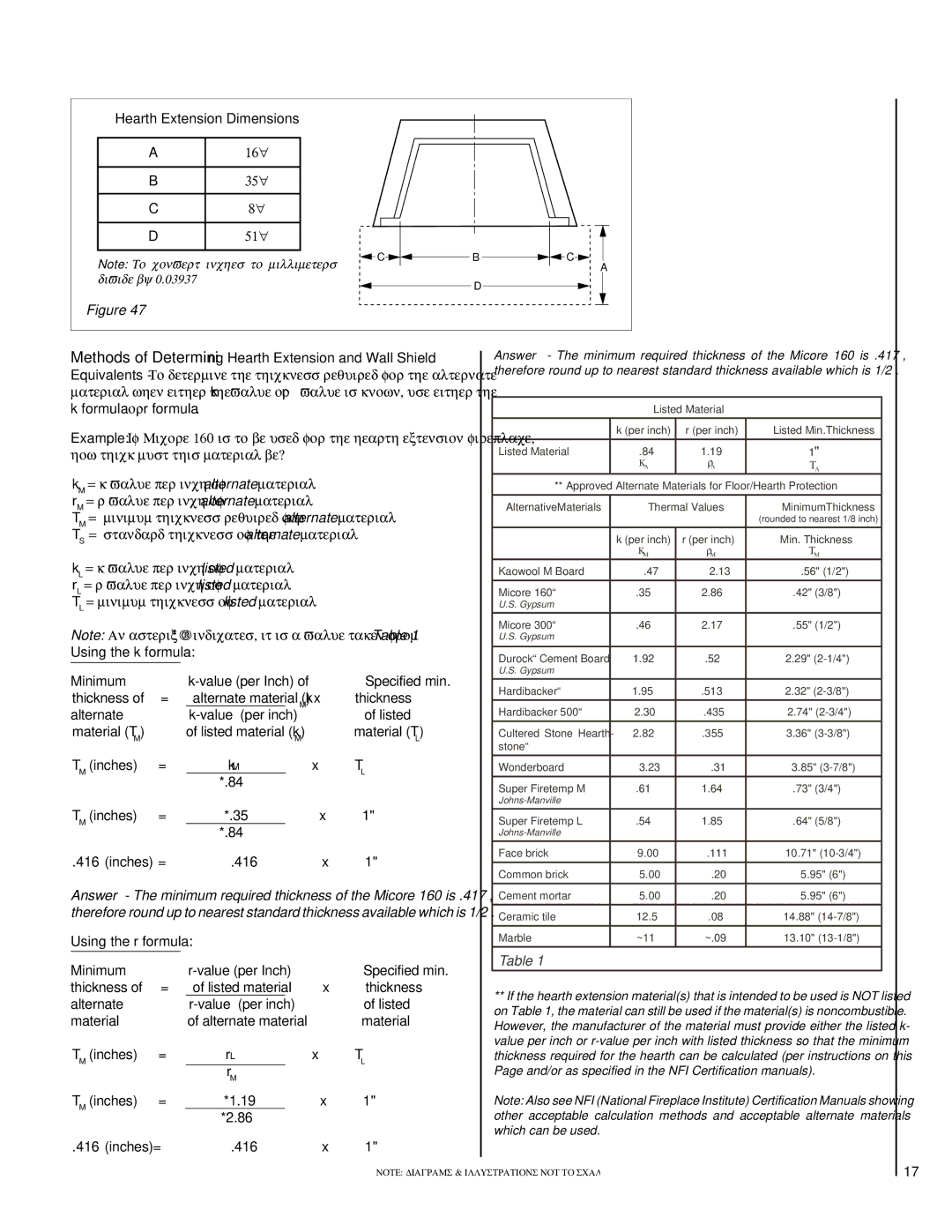

Hearth Extension Dimensions |

|

|

| |

A | 16" |

|

|

|

B | 35" |

|

|

|

C | 8" |

|

|

|

D | 51" |

|

|

|

Note: To convert | inches to millimeters | C | B | C |

|

| A | ||

divide by 0.03937 |

|

| D |

|

|

|

|

| |

Figure 47

Methods of Determining Hearth Extension and Wall Shield

Equivalents - To determine the thickness required for the alternate material when either the “k” value or “r” value is known, use either the k formula or r formula.

Example: If Micore 160 is to be used for the hearth extension fireplace, how thick must this material be?

kM = k value per inch of alternate material rM = r value per inch of alternate material

TM = minimum thickness required for alternate material TS = standard thickness of the alternate material

kL = k value per inch of listed material rL = r value per inch of listed material

TL = minimum thickness of listed material

Note: An asterix “*” indicates, it is a value taken from Table 1.

Using the k formula:

Minimum |

|

| Specified min. | |

thickness of | = | alternate material (kM) x | thickness | |

alternate |

|

| of listed | |

material (TM) |

| of listed material (kM) |

| material (TL) |

TM (inches) | = | kM | x | TL |

|

| *.84 |

|

|

TM (inches) | = | *.35 | x | 1" |

|

| *.84 |

|

|

.416 (inches) = | .416 | x | 1" | |

Answer - The minimum required thickness of the Micore 160 is .417”, therefore round up to nearest standard thickness available which is 1/2”.

Using the r formula:

Minimum |

|

| Specified min. | |

thickness of | = | of listed material | x | thickness |

alternate |

|

| of listed | |

material |

| of alternate material |

| material |

TM (inches) | = | rL | x | TL |

|

| rM |

|

|

TM (inches) | = | *1.19 | x | 1" |

|

| *2.86 |

|

|

.416 (inches)= | .416 | x | 1" | |

Answer - The minimum required thickness of the Micore 160 is .417”, therefore round up to nearest standard thickness available which is 1/2”.

Listed Material

| k (per inch) | r (per inch) | Listed Min.Thickness |

Listed Material | .84 | 1.19 | 1" |

| KL | rL | TL |

** Approved Alternate Materials for Floor/Hearth Protection | |||

AlternativeMaterials | Thermal Values | MinimumThickness | |

|

|

| (rounded to nearest 1/8 inch) |

| k (per inch) | r (per inch) | Min. Thickness |

| KM | rM | TM |

Kaowool M Board | .47 | 2.13 | .56" (1/2") |

Micore 160™ | .35 | 2.86 | .42" (3/8") |

U.S. Gypsum |

|

|

|

Micore 300™ | .46 | 2.17 | .55" (1/2") |

U.S. Gypsum |

|

|

|

Durock™ Cement Board | 1.92 | .52 | 2.29" |

U.S. Gypsum |

|

|

|

Hardibacker™ | 1.95 | .513 | 2.32" |

Hardibacker 500™ | 2.30 | .435 | 2.74" |

Cultered Stone Hearth- | 2.82 | .355 | 3.36" |

stone™ |

|

|

|

Wonderboard | 3.23 | .31 | 3.85" |

Super Firetemp M | .61 | 1.64 | .73" (3/4") |

|

|

| |

Super Firetemp L | .54 | 1.85 | .64" (5/8") |

|

|

| |

Face brick | 9.00 | .111 | 10.71" |

Common brick | 5.00 | .20 | 5.95" (6") |

Cement mortar | 5.00 | .20 | 5.95" (6") |

Ceramic tile | 12.5 | .08 | 14.88" |

Marble | ~11 | ~.09 | 13.10" |

Table 1 |

|

|

|

**If the hearth extension material(s) that is intended to be used is NOT listed on Table 1, the material can still be used if the material(s) is noncombustible. However, the manufacturer of the material must provide either the listed k- value per inch or

Note: Also see NFI (National Fireplace Institute) Certification Manuals showing other acceptable calculation methods and acceptable alternate materials which can be used.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

17