BS5839 specifications

System Sensor BS5839 is a standard that pertains to fire detection and alarm systems, providing guidelines for the design, installation, and maintenance of these essential safety tools. It is crucial for safeguarding lives and property, ensuring that fire detection systems are effective and reliable. The BS5839 standard, established in the UK, covers a wide range of fire alarm system types, including conventional, addressable, and wireless systems.One of the main features of BS5839 is its comprehensive classification of fire detection systems. The standard divides systems into categories based on the level of risk and the environment in which the system will operate. This classification helps ensure that the system installed meets the specific needs of the building and its occupants. For example, Category L systems are meant for life safety, while Category P systems are designed to protect property.

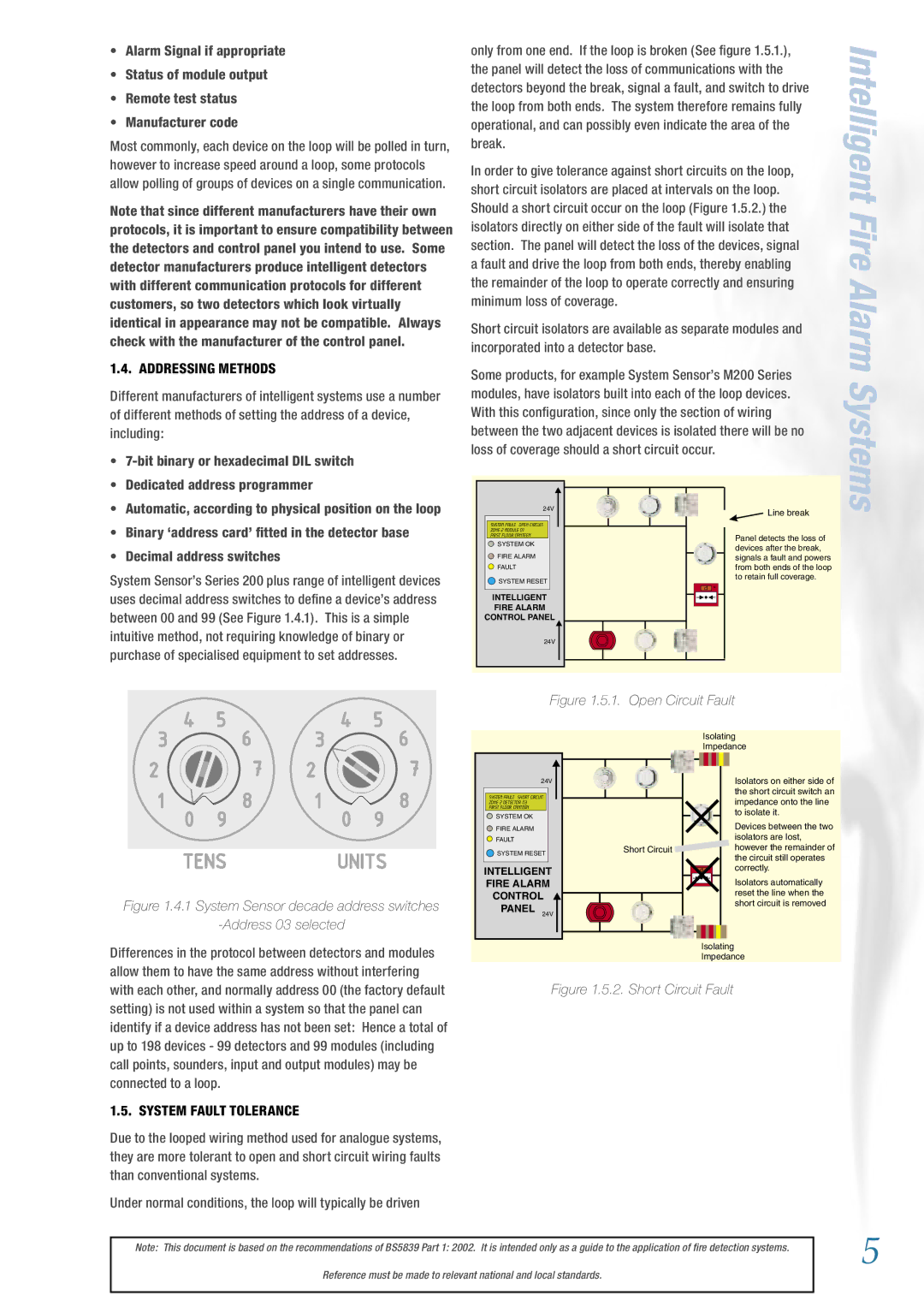

The technologies underpinning BS5839 include various types of detectors, alarm devices, and control panels. Smoke detectors, heat detectors, and multi-sensor detectors are prominent among the devices specified in the standard. Smoke detectors use photoelectric or ionization principles to detect smoke and signal an alarm, while heat detectors respond to temperature changes. Multi-sensor detectors combine both smoke and heat detection technologies to provide a more reliable response to fire conditions.

Another key characteristic of BS5839 is the emphasis on regular testing and maintenance. The standard outlines procedures to ensure that systems remain operational and effective over time. This includes routine system checks, functional testing, and more in-depth inspections at regular intervals. Ensuring that systems are maintained according to BS5839 is vital for compliance with insurance requirements and for safeguarding against potential legal liabilities.

Furthermore, BS5839 highlights the importance of staff training and awareness. It emphasizes that personnel responsible for fire safety must be adequately trained in the operation and response to fire alarm systems. This ensures that in the event of a fire, occupants are prompted to take appropriate action and evacuate safely.

In summary, System Sensor BS5839 provides a crucial framework for fire detection and alarm systems. Its classification of systems, incorporation of advanced technologies, and emphasis on maintenance all contribute to enhanced safety and compliance, protecting lives and property effectively.