www.ti.com | Equipment |

1.4Recommended Operating Conditions

Table 2. Recommended Operating Conditions

Symbol | Description | Min | Typ | Max | Unit |

|

|

|

|

|

|

Vin, J1 | Supply Voltage | 9.5 | 10.0 | 10.5 | V |

|

|

|

|

|

|

Vout, J4 | Battery Voltage | 4 |

| 7.5 | V |

|

|

|

|

|

|

Iin | Supply Current | 0 |

| 0.5 | A |

|

|

|

|

|

|

Iout | Charge Current | 0 |

| 0.5 | A |

|

|

|

|

|

|

2 Equipment

2.1Power Supplies

Power Supply #1 (PS#1): Adjustable from 0 to ≥ 10 VDC at ≥ 1A; used for input J1.

Power Supply #2 (PS#2): Adjustable from 0 to ≥ 10 VDC at ≥ 1.5A; used for Battery Load Board.

2.2Loads

Load #1: Battery Load Circuit Board,

2.3Meters

Three Fluke 75 DMMs (equivalent or better).

3Equipment Setup

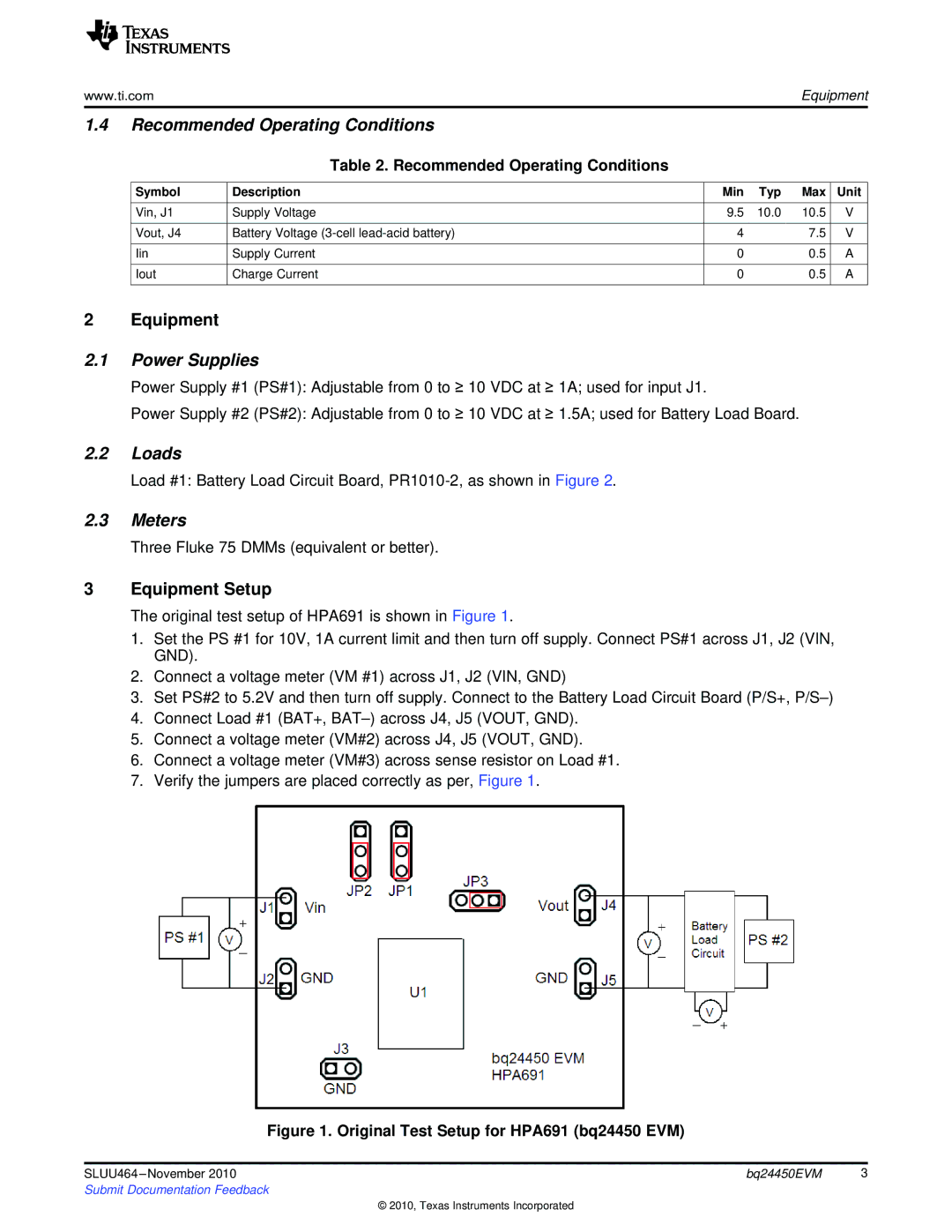

The original test setup of HPA691 is shown in Figure 1.

1.Set the PS #1 for 10V, 1A current limit and then turn off supply. Connect PS#1 across J1, J2 (VIN, GND).

2.Connect a voltage meter (VM #1) across J1, J2 (VIN, GND)

3.Set PS#2 to 5.2V and then turn off supply. Connect to the Battery Load Circuit Board (P/S+,

4.Connect Load #1 (BAT+,

5.Connect a voltage meter (VM#2) across J4, J5 (VOUT, GND).

6.Connect a voltage meter (VM#3) across sense resistor on Load #1.

7.Verify the jumpers are placed correctly as per, Figure 1.

Figure 1. Original Test Setup for HPA691 (bq24450 EVM)

SLUU464 | bq24450EVM | 3 |

Submit Documentation Feedback |

|

|

© 2010, Texas Instruments Incorporated