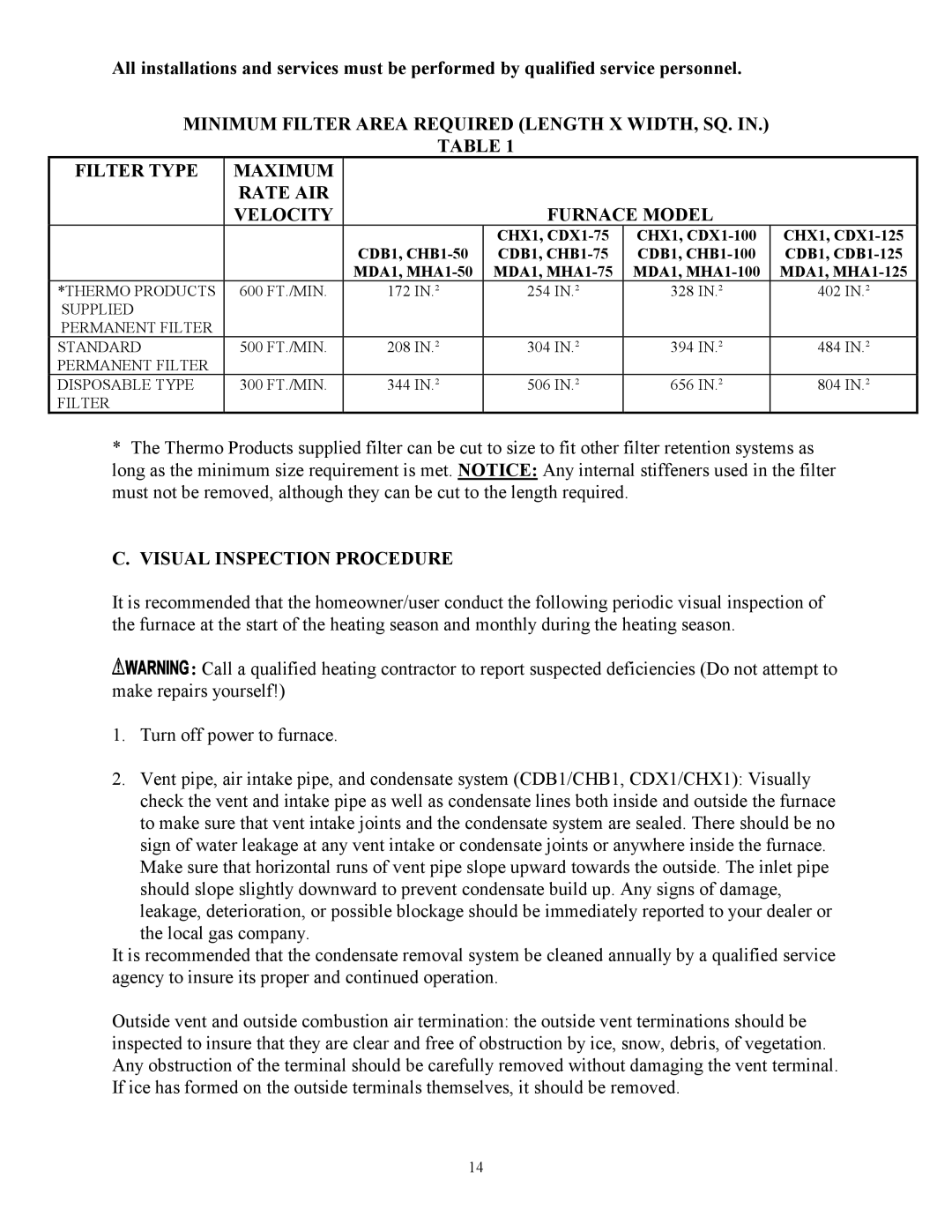

MDA1-100, CDB1-125, CHX1-75, CHB1-125, CDB1-50 specifications

Thermo Products is a recognized name in the heating and cooling industry, offering a range of solutions designed to meet various environmental control needs. Among their impressive lineup are the MDA1-100, CHB1-50, CHB1-75, CHX1-100, and CHX1-75 models. Each model boasts unique features and technologies that cater to both residential and commercial applications.The MDA1-100 is an advanced air conditioning unit designed for maximum efficiency. It employs cutting-edge inverter technology, which adjusts the compressor speed to suit the cooling requirements dynamically. This not only results in lower energy consumption but also ensures quieter operation and improved temperature consistency. With a cooling capacity of 10,000 BTU, it is ideal for medium-sized spaces.

Moving on to the CHB1 series, both the CHB1-50 and CHB1-75 are heat pump units that offer both heating and cooling functionalities. The CHB1-50 features a heating capacity of 5,000 BTU, optimal for smaller applications, while the CHB1-75 can provide up to 7,500 BTU, making it suitable for slightly larger areas. These models utilize a unique refrigeration cycle that maximizes heat recovery, enabling efficient energy use during colder months while providing reliable cooling in warm weather.

Then we have the CHX series, which includes the CHX1-100 and CHX1-75. These high-performance units are designed to handle harsher climates, equipped with advanced defrost cycles to ensure operational reliability. The CHX1-100 has a robust cooling capacity of 10,000 BTU, catering to larger locations, while the CHX1-75 is adept for medium-sized areas with its 7,500 BTU capacity. Both models excel in energy efficiency, utilizing variable speed compressors for optimal performance.

A standout characteristic across these models is their straightforward installation and user-friendly interfaces. Many units are equipped with smart technologies, allowing users to monitor and control their systems remotely via smartphone applications. Additionally, the units are built with durable materials designed to withstand the rigors of different environments, ensuring longevity and reduced maintenance costs.

In conclusion, Thermo Products' MDA1-100, CHB1-50, CHB1-75, CHX1-100, and CHX1-75 collectively embody a commitment to innovation in climate control. They offer efficiency, adaptability, and advanced technology that make them excellent choices for any heating and cooling needs. Whether for residential or commercial application, these models provide reliable performance, ensuring comfort throughout the year.