All installations and services must be performed by qualified service personnel.

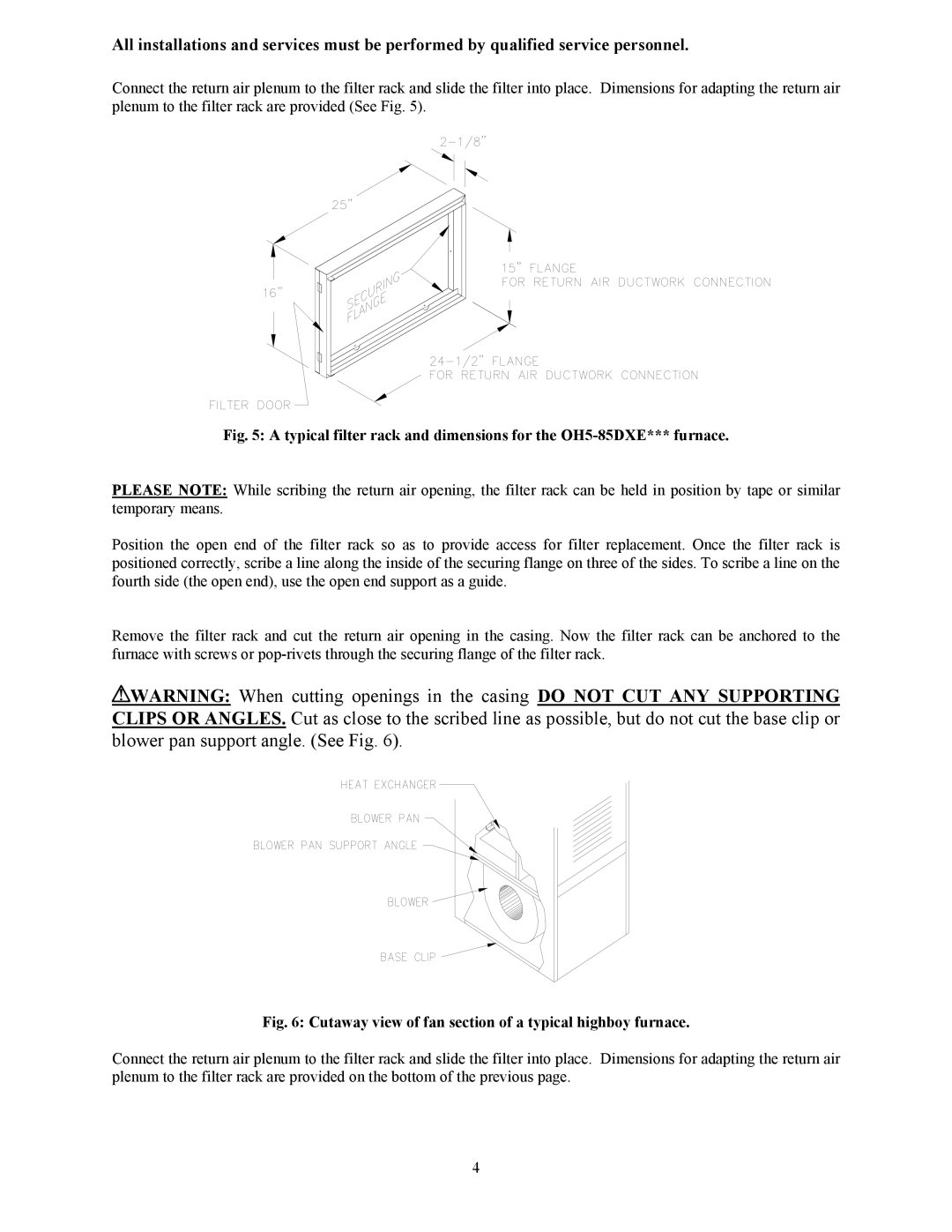

Connect the return air plenum to the filter rack and slide the filter into place. Dimensions for adapting the return air plenum to the filter rack are provided (See Fig. 5).

Fig. 5: A typical filter rack and dimensions for the OH5-85DXE*** furnace.

PLEASE NOTE: While scribing the return air opening, the filter rack can be held in position by tape or similar temporary means.

Position the open end of the filter rack so as to provide access for filter replacement. Once the filter rack is positioned correctly, scribe a line along the inside of the securing flange on three of the sides. To scribe a line on the fourth side (the open end), use the open end support as a guide.

Remove the filter rack and cut the return air opening in the casing. Now the filter rack can be anchored to the furnace with screws or

cWARNING: When cutting openings in the casing DO NOT CUT ANY SUPPORTING CLIPS OR ANGLES. Cut as close to the scribed line as possible, but do not cut the base clip or blower pan support angle. (See Fig. 6).

Fig. 6: Cutaway view of fan section of a typical highboy furnace.

Connect the return air plenum to the filter rack and slide the filter into place. Dimensions for adapting the return air plenum to the filter rack are provided on the bottom of the previous page.

4