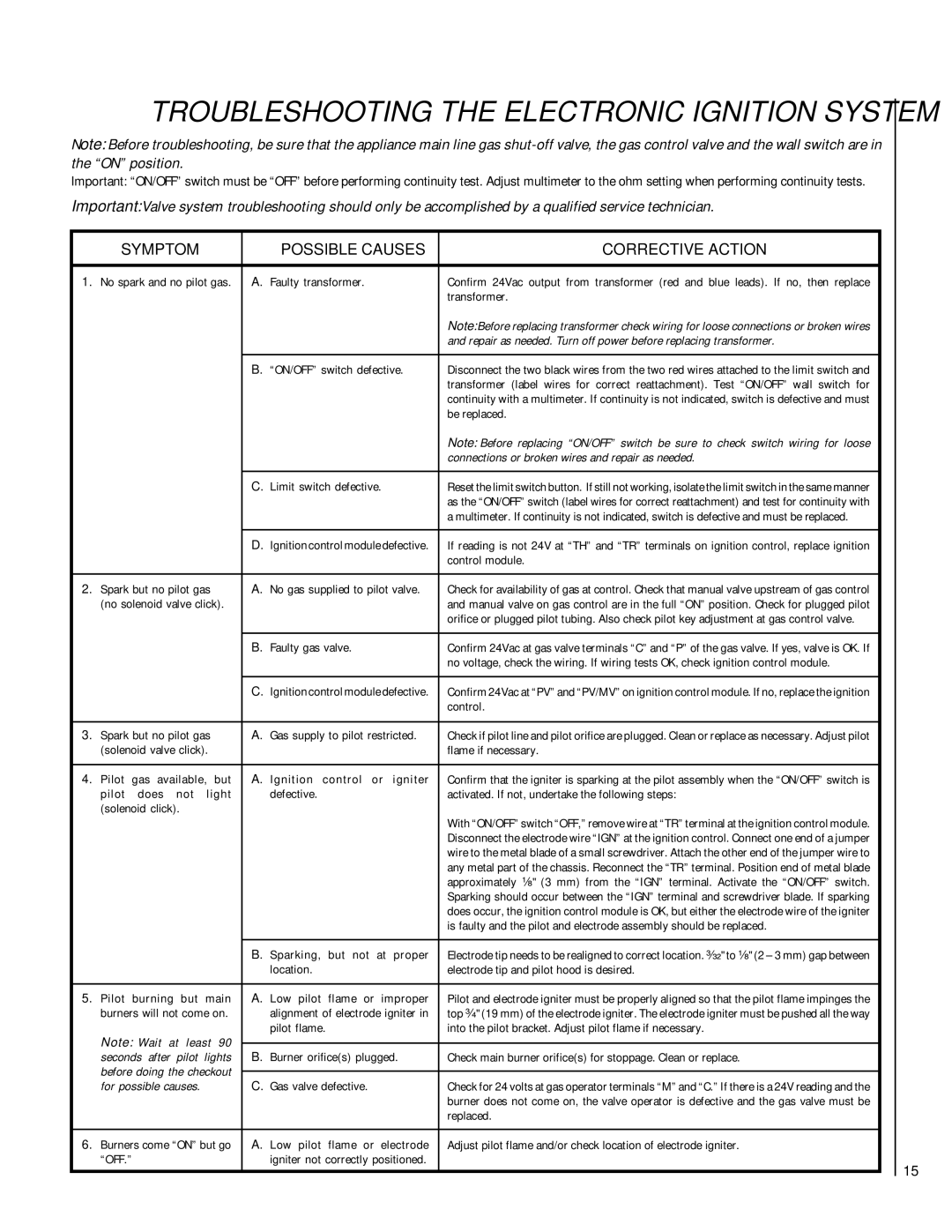

TROUBLESHOOTING THE ELECTRONIC IGNITION SYSTEM

Note: Before troubleshooting, be sure that the appliance main line gas

Important: “ON/OFF” switch must be “OFF” before performing continuity test. Adjust multimeter to the ohm setting when performing continuity tests.

Important: Valve system troubleshooting should only be accomplished by a qualified service technician.

SYMPTOM |

| POSSIBLE CAUSES | CORRECTIVE ACTION | |

1. No spark and no pilot gas. | A. Faulty transformer. | Confirm 24Vac output from transformer (red and blue leads). If no, then replace | ||

|

|

|

| transformer. |

|

|

|

| Note: Before replacing transformer check wiring for loose connections or broken wires |

|

|

|

| and repair as needed. Turn off power before replacing transformer. |

|

|

|

|

|

|

|

| B. “ON/OFF” switch defective. | Disconnect the two black wires from the two red wires attached to the limit switch and |

|

|

|

| transformer (label wires for correct reattachment). Test “ON/OFF” wall switch for |

|

|

|

| continuity with a multimeter. If continuity is not indicated, switch is defective and must |

|

|

|

| be replaced. |

|

|

|

| Note: Before replacing “ON/OFF” switch be sure to check switch wiring for loose |

|

|

|

| connections or broken wires and repair as needed. |

|

|

|

|

|

|

|

| C. Limit switch defective. | Reset the limit switch button. If still not working, isolate the limit switch in the same manner |

|

|

|

| as the “ON/OFF” switch (label wires for correct reattachment) and test for continuity with |

|

|

|

| a multimeter. If continuity is not indicated, switch is defective and must be replaced. |

|

|

|

|

|

|

|

| D. Ignition control module defective. | If reading is not 24V at “TH” and “TR” terminals on ignition control, replace ignition |

|

|

|

| control module. |

|

|

| ||

2. Spark but no pilot gas | A. No gas supplied to pilot valve. | Check for availability of gas at control. Check that manual valve upstream of gas control | ||

(no solenoid valve click). |

| and manual valve on gas control are in the full “ON” position. Check for plugged pilot | ||

|

|

|

| orifice or plugged pilot tubing. Also check pilot key adjustment at gas control valve. |

|

|

|

|

|

|

|

| B. Faulty gas valve. | Confirm 24Vac at gas valve terminals “C” and “P” of the gas valve. If yes, valve is OK. If |

|

|

|

| no voltage, check the wiring. If wiring tests OK, check ignition control module. |

|

|

|

|

|

|

|

| C. Ignition control module defective. | Confirm 24Vac at “PV” and “PV/MV” on ignition control module. If no, replace the ignition |

|

|

|

| control. |

|

|

| ||

3. Spark but no pilot gas | A. Gas supply to pilot restricted. | Check if pilot line and pilot orifice are plugged. Clean or replace as necessary. Adjust pilot | ||

(solenoid valve click). |

| flame if necessary. | ||

|

|

| ||

4. Pilot gas available, but | A. Ignition control or igniter | Confirm that the igniter is sparking at the pilot assembly when the “ON/OFF” switch is | ||

pilot does | not | light | defective. | activated. If not, undertake the following steps: |

(solenoid click). |

|

| With “ON/OFF” switch “OFF,” remove wire at “TR” terminal at the ignition control module. | |

|

|

|

| |

|

|

|

| Disconnect the electrode wire “IGN” at the ignition control. Connect one end of a jumper |

|

|

|

| wire to the metal blade of a small screwdriver. Attach the other end of the jumper wire to |

|

|

|

| any metal part of the chassis. Reconnect the “TR” terminal. Position end of metal blade |

|

|

|

| approximately ¹⁄₈" (3 mm) from the “IGN” terminal. Activate the “ON/OFF” switch. |

|

|

|

| Sparking should occur between the “IGN” terminal and screwdriver blade. If sparking |

|

|

|

| does occur, the ignition control module is OK, but either the electrode wire of the igniter |

|

|

|

| is faulty and the pilot and electrode assembly should be replaced. |

|

|

|

|

|

|

|

| B. Sparking, but not at proper | Electrode tip needs to be realigned to correct location. ³⁄₃₂" to ¹⁄₈" (2 – 3 mm) gap between |

|

|

| location. | electrode tip and pilot hood is desired. |

|

|

| ||

5. Pilot burning but main | A. Low pilot flame or improper | Pilot and electrode igniter must be properly aligned so that the pilot flame impinges the | ||

burners will not come on. | alignment of electrode igniter in | top ³⁄₄" (19 mm) of the electrode igniter. The electrode igniter must be pushed all the way | ||

Note: Wait at least 90 | pilot flame. | into the pilot bracket. Adjust pilot flame if necessary. | ||

|

| |||

|

| |||

seconds after | pilot | lights | B. Burner orifice(s) plugged. | Check main burner orifice(s) for stoppage. Clean or replace. |

before doing the checkout |

|

| ||

|

| |||

for possible causes. |

| C. Gas valve defective. | Check for 24 volts at gas operator terminals “M” and “C.” If there is a 24V reading and the | |

|

|

|

| burner does not come on, the valve operator is defective and the gas valve must be |

|

|

|

| replaced. |

|

|

| ||

6. Burners come “ON” but go | A. Low pilot flame or electrode | Adjust pilot flame and/or check location of electrode igniter. | ||

“OFF.” |

|

| igniter not correctly positioned. |

|

15