SECTION8: MAINTAININGYOURLAWNTRACTOR

NOTE: Refer to MaintenanceCharton page 31 for a reference of recommended maintenance intervals.

WARNING: Before performing any

maintenance or repairs, disengage PTO, set parking brake, stop engine and remove key to prevent unintended starting.

Engine

Maintenance, repair, or replacement of the emission control devices and systems, which are being done at the customer's expense, may be performed by any engine repair establishment or individual. Warranty repairs must be performed by an authorized Toro service dealer.

EngineOil

The

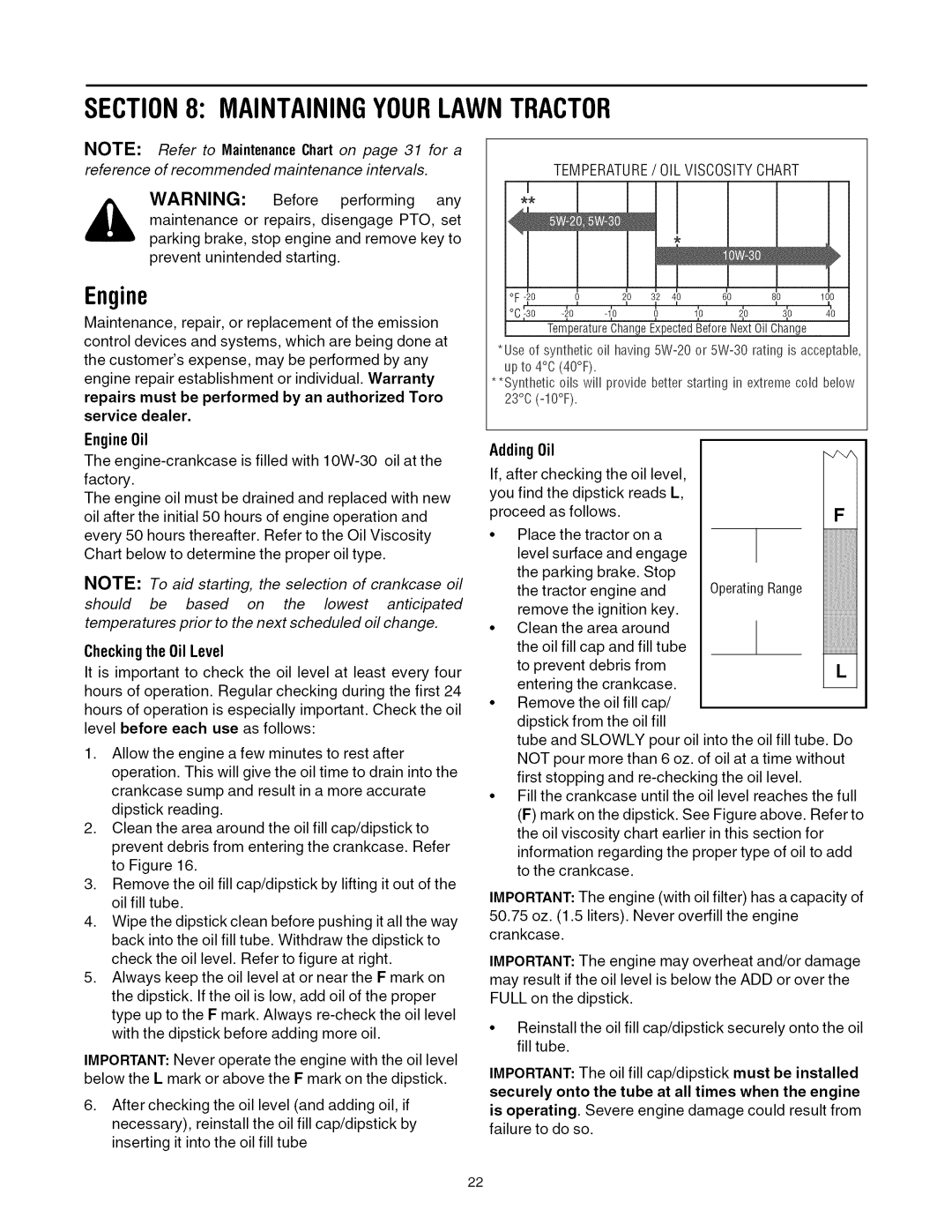

The engine oil must be drained and replaced with new oil after the initial 50 hours of engine operation and every 50 hours thereafter. Refer to the Oil Viscosity Chart below to determine the proper oil type.

NOTE: To aid starting, the selection of crankcase oil

should be based on the lowest anticipated temperatures prior to the next scheduled oil change.

Checkingthe 0il Level

TEMPERATURE/ OIL VISCOSITYCHART

I

oF | 0 | 2:0 | 32 | 40 | 6_0 | 8! |

| ||

|

|

|

| I |

|

|

|

|

|

°C | )30 | 0 | 1;0 |

| 2_0 | 3'0 | 40 |

TemperatureChangeExpectedBeforeNextOilChange

*Use of synthetic oHhaving 5W=20or 5W=30 rating is acceptaNe, up to 4°0 (40%),

**Synthetic oils wHnprovide better starting in extreme condbenow 23% (=10%),

Adding Oil

If, after checking the oil level, you find the dipstick reads L, proceed as follows.

•Place the tractor on a

level surface and engage

the parking brake. Stop

the tractor engine and OperatingRange remove the ignition key.

•Clean the area around the oil fill cap and fill tube

It is important to check the oil level at least every four hours of operation. Regular checking during the first 24

to prevent debris from entering the crankcase.

iiiiiiiiiiiiiiii!

hours of operation is especially important. Check the oil level before each use as follows:

1.Allow the engine a few minutes to rest after operation. This will give the oil time to drain into the crankcase sump and result in a more accurate dipstick reading.

2.Clean the area around the oil fill cap/dipstick to prevent debris from entering the crankcase. Refer to Figure 16.

3.Remove the oil fill cap/dipstick by lifting it out of the oil fill tube.

4.Wipe the dipstick clean before pushing it all the way back into the oil fill tube. Withdraw the dipstick to check the oil level. Refer to figure at right.

5.Always keep the oil level at or near the F mark on the dipstick. If the oil is low, add oil of the proper type up to the F mark. Always

IMPORTANT: Never operate the engine with the oil level below the L mark or above the F mark on the dipstick.

6.After checking the oil level (and adding oil, if necessary), reinstall the oil fill cap/dipstick by inserting it into the oil fill tube

•Remove the oil fill cap/ dipstick from the oil fill

tube and SLOWLY pour oil into the oil fill tube. Do NOT pour more than 6 oz. of oil at a time without first stopping and

Fill the crankcase until the oil level reaches the full

(F)mark on the dipstick. See Figure above. Refer to the oil viscosity chart earlier in this section for information regarding the proper type of oil to add to the crankcase.

IMPORTANT: The engine (with oil filter) has a capacity of

50.75oz. (1.5 liters). Never overfill the engine crankcase.

IMPORTANT: The engine may overheat and/or damage may result if the oil level is below the ADD or over the FULL on the dipstick.

•Reinstall the oil fill cap/dipstick securely onto the oil fill tube.

IMPORTANT:The oil fill cap/dipstick must be installed securely onto the tube at all times when the engine is operating. Severe engine damage could result from failure to do so.

22