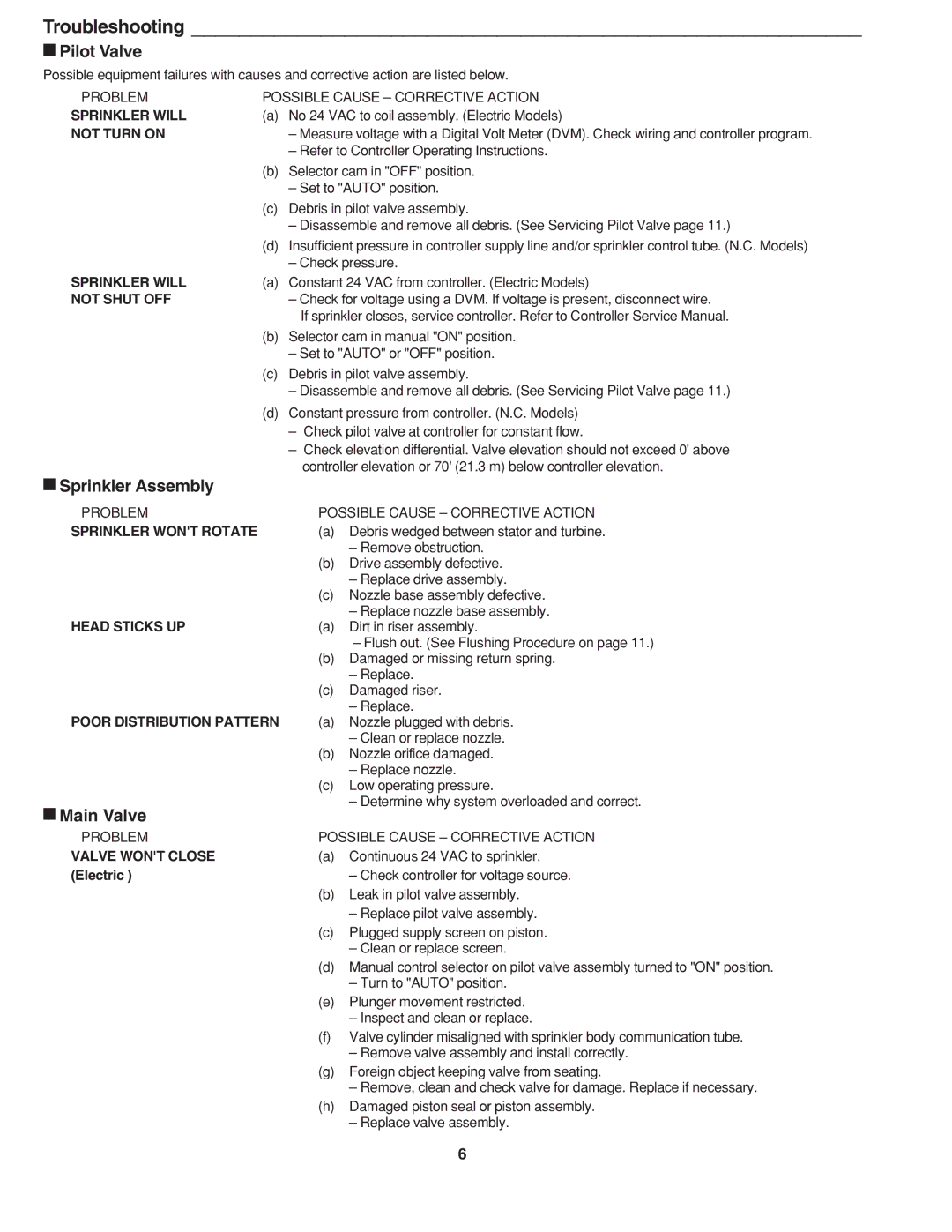

Troubleshooting _________________________________________________________

■Pilot Valve

Possible equipment failures with causes and corrective action are listed below.

PROBLEM | POSSIBLE CAUSE – CORRECTIVE ACTION |

SPRINKLER WILL | (a) No 24 VAC to coil assembly. (Electric Models) |

NOT TURN ON | – Measure voltage with a Digital Volt Meter (DVM). Check wiring and controller program. |

| – Refer to Controller Operating Instructions. |

| (b) Selector cam in "OFF" position. |

| – Set to "AUTO" position. |

| (c) Debris in pilot valve assembly. |

| – Disassemble and remove all debris. (See Servicing Pilot Valve page 11.) |

| (d) Insufficient pressure in controller supply line and/or sprinkler control tube. (N.C. Models) |

| – Check pressure. |

SPRINKLER WILL | (a) Constant 24 VAC from controller. (Electric Models) |

NOT SHUT OFF | – Check for voltage using a DVM. If voltage is present, disconnect wire. |

| If sprinkler closes, service controller. Refer to Controller Service Manual. |

(b)Selector cam in manual "ON" position.

–Set to "AUTO" or "OFF" position.

(c)Debris in pilot valve assembly.

–Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d)Constant pressure from controller. (N.C. Models)

–Check pilot valve at controller for constant flow.

–Check elevation differential. Valve elevation should not exceed 0' above controller elevation or 70' (21.3 m) below controller elevation.

■Sprinkler Assembly

PROBLEM | POSSIBLE CAUSE – CORRECTIVE ACTION | |

SPRINKLER WON'T ROTATE | (a) | Debris wedged between stator and turbine. |

|

| – Remove obstruction. |

| (b) | Drive assembly defective. |

|

| – Replace drive assembly. |

| (c) | Nozzle base assembly defective. |

HEAD STICKS UP |

| – Replace nozzle base assembly. |

(a) | Dirt in riser assembly. | |

|

| – Flush out. (See Flushing Procedure on page 11.) |

| (b) | Damaged or missing return spring. |

|

| – Replace. |

| (c) | Damaged riser. |

POOR DISTRIBUTION PATTERN |

| – Replace. |

(a) | Nozzle plugged with debris. | |

|

| – Clean or replace nozzle. |

| (b) | Nozzle orifice damaged. |

|

| – Replace nozzle. |

| (c) | Low operating pressure. |

■ Main Valve |

| – Determine why system overloaded and correct. |

|

| |

PROBLEM | POSSIBLE CAUSE – CORRECTIVE ACTION | |

VALVE WON'T CLOSE | (a) | Continuous 24 VAC to sprinkler. |

(Electric ) |

| – Check controller for voltage source. |

| (b) | Leak in pilot valve assembly. |

|

| – Replace pilot valve assembly. |

| (c) | Plugged supply screen on piston. |

|

| – Clean or replace screen. |

| (d) | Manual control selector on pilot valve assembly turned to "ON" position. |

|

| – Turn to "AUTO" position. |

| (e) | Plunger movement restricted. |

|

| – Inspect and clean or replace. |

| (f) | Valve cylinder misaligned with sprinkler body communication tube. |

|

| – Remove valve assembly and install correctly. |

| (g) | Foreign object keeping valve from seating. |

|

| – Remove, clean and check valve for damage. Replace if necessary. |

| (h) | Damaged piston seal or piston assembly. |

|

| – Replace valve assembly. |

6