Regular Dealer Maintenance

For regular dealer maintenance please refer to

www.acca.org/industry/quality

To ensure proper operation of your furnace, the recommended dealer inspection is once a year, before the heating season. Regular maintenance must be performed by a qualified service professional.

The servicer should perform steps

The homeowner should perform the visual inspection in step 1 monthly when cleaning the furnace filter.

Unless it is an emergency, never stop the heating system by shutting off the main power.

If the main power to your air conditioner is ever disconnected for more than three hours, turn off the thermostat. Then wait for at least three more hours after the power has been restored before turning the thermostat back on. Failure to follow this procedure could result in damage to your furnace.

The following warning complies with State of California law, Proposition 65.

HAZARDOUS GASES

Exposure to fuel substances or

HAZARDOUS GASES

Unit is equipped with a blower door switch which cuts power to blower and gas valve causing shutdown when door is removed. Unit must not be altered to allow operation with the blower door removed. Operation with doors removed or ajar can permit the escape of dangerous fumes. All panels must be securely closed at all times for safe operation of the furnace. Failure to follow this warning could result in property damage, personal injury or death.

EXPLOSION HAZARD

In the event that electrical, fuel or mechanical failures occur, SHUT off the gas supply at the manual gas SHUT OFF valve, located ON THE SUPPLY GAS PIPING COMING INTO THE FURNACE, BEFORE TURNING OFF THE electrical power to the furnace. contact servicer.

Failure to follow this warning could result in property damage, personal injury or death.

Do NOT touch igniter. It is extremely hot.

EXPLOSION HAZARD

Should overheating occur, or the gas supply fail to shut off, shut off the manual gas valve to the furnace before shutting off the electrical supply.

Failure to follow this warning could result in property damage, personal injury or death.

1.GENERAL INSPECTION – Examine the furnace installation for the following items:

a.All flue product carrying areas external to the furnace

(i.e. chimney, vent connector) are clear and free of obstruction.

b.The vent connector is in place, slopes upward and is physically sound without holes or excessive corrosion.

c.The return air duct connection(s) is physically sound, is sealed to the furnace and terminates outside the space containing the furnace.

d.The physical support of the furnace should be sound without sagging, cracks, gaps, etc., around the base so as to provide a seal between the support and the base.

e.There are no obvious signs of deterioration of the furnace.

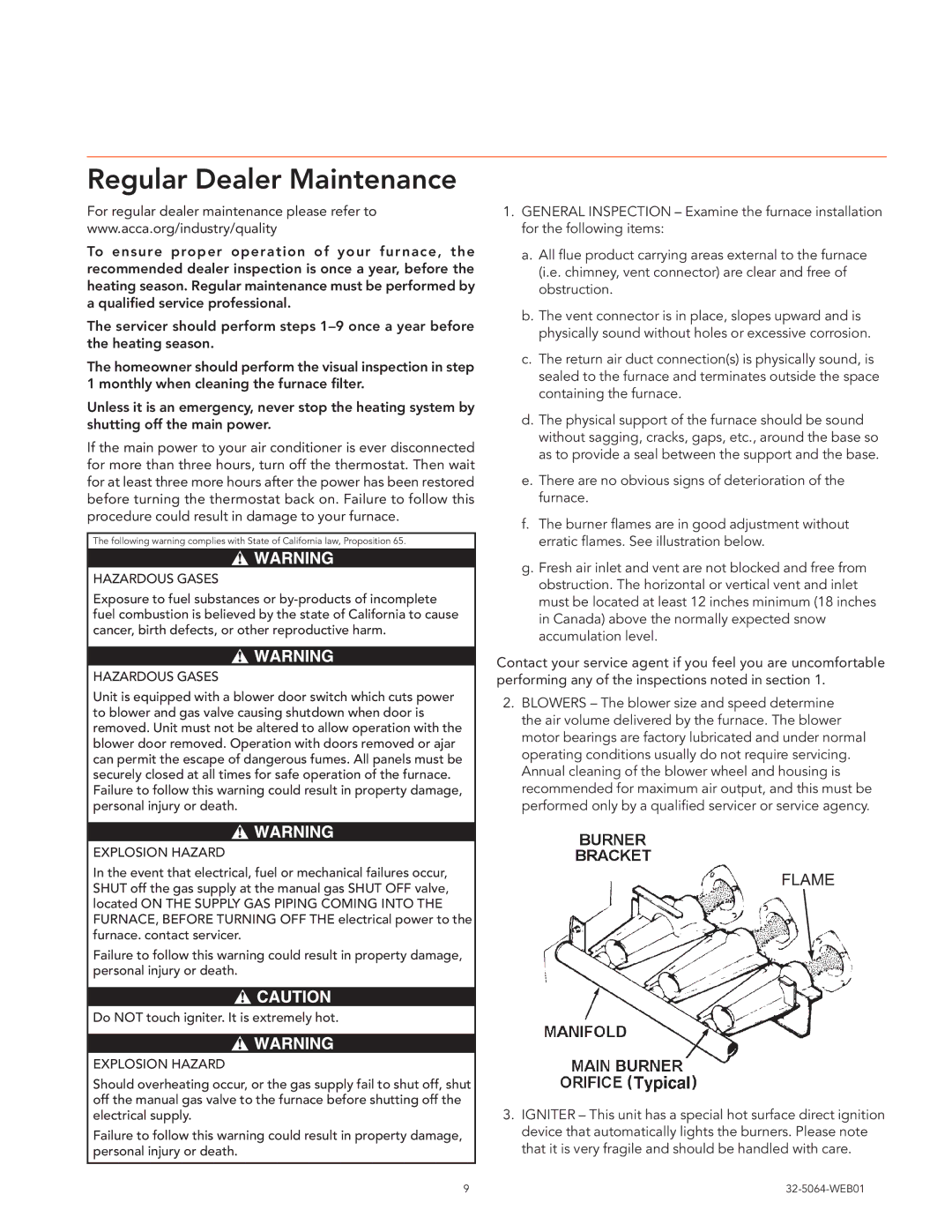

f.The burner flames are in good adjustment without erratic flames. See illustration below.

g.Fresh air inlet and vent are not blocked and free from obstruction. The horizontal or vertical vent and inlet must be located at least 12 inches minimum (18 inches in Canada) above the normally expected snow accumulation level.

Contact your service agent if you feel you are uncomfortable performing any of the inspections noted in section 1.

2.BLOWERS – The blower size and speed determine the air volume delivered by the furnace. The blower motor bearings are factory lubricated and under normal operating conditions usually do not require servicing.

Annual cleaning of the blower wheel and housing is recommended for maximum air output, and this must be performed only by a qualified servicer or service agency.

FLAME

3.IGNITER – This unit has a special hot surface direct ignition device that automatically lights the burners. Please note that it is very fragile and should be handled with care.

9 |