Reversing Relay

Installation and Operation

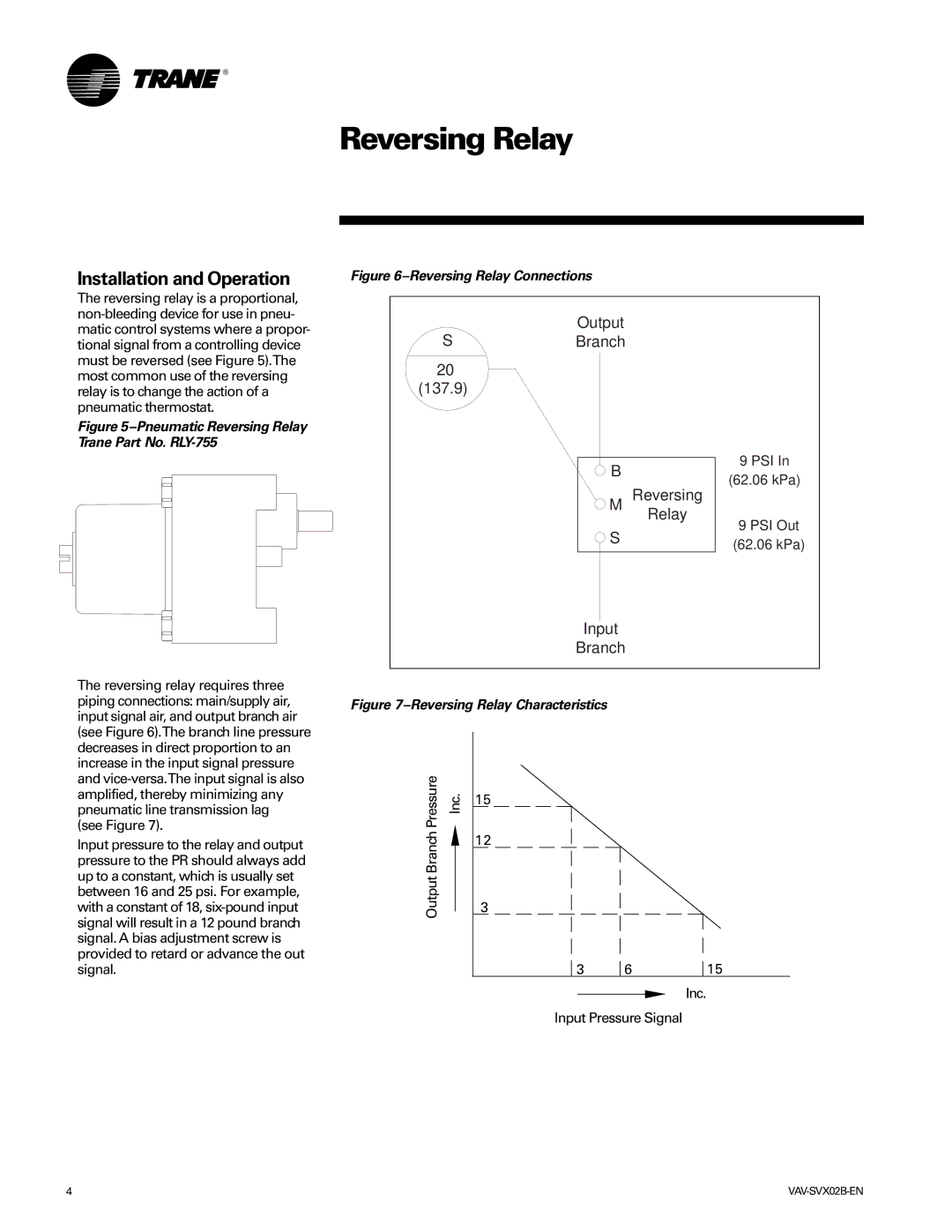

Figure 6–Reversing Relay Connections

The reversing relay is a proportional,

Figure 5–Pneumatic Reversing Relay Trane Part No. RLY-755

Output

SBranch

20

(137.9)

B

M Reversing

Relay

S

9 PSI In

(62.06 kPa)

9 PSI Out

(62.06 kPa)

The reversing relay requires three piping connections: main/supply air, input signal air, and output branch air (see Figure 6).The branch line pressure decreases in direct proportion to an increase in the input signal pressure and

(see Figure 7).

Input pressure to the relay and output pressure to the PR should always add up to a constant, which is usually set between 16 and 25 psi. For example, with a constant of 18,

Input

Branch

Figure 7–Reversing Relay Characteristics

Pressure | Inc. | 15 | |

Branch |

|

| 12 |

Output |

|

| 3 |

|

|

| |

3 | 6 | 15 |

Inc.

Input Pressure Signal

4 |