Calibration

Procedures

Calibration Procedure (Steps

1.Be sure the PVR is installed correctly and that all connections are hooked up to the proper ports. See Figure 9 for unit application.

2.Remove the caps on the tees which are connected to the lines to the flow sensor. Connect a

3.Remove the thermostat line and connect a hand pump with a

4.Tee a

Normally-OpenValve

Normally-Open Valve

5.Set port “T” at 0 psi.

6.Monitor the delta P and adjust the

7.Set port “T” input at 16 psi or greater with the hand pump.

8.Monitor the delta P and adjust the

9.Set port “T” at 0 psi.

10.Monitor the minimum flow delta P. If it is not correct, adjust the

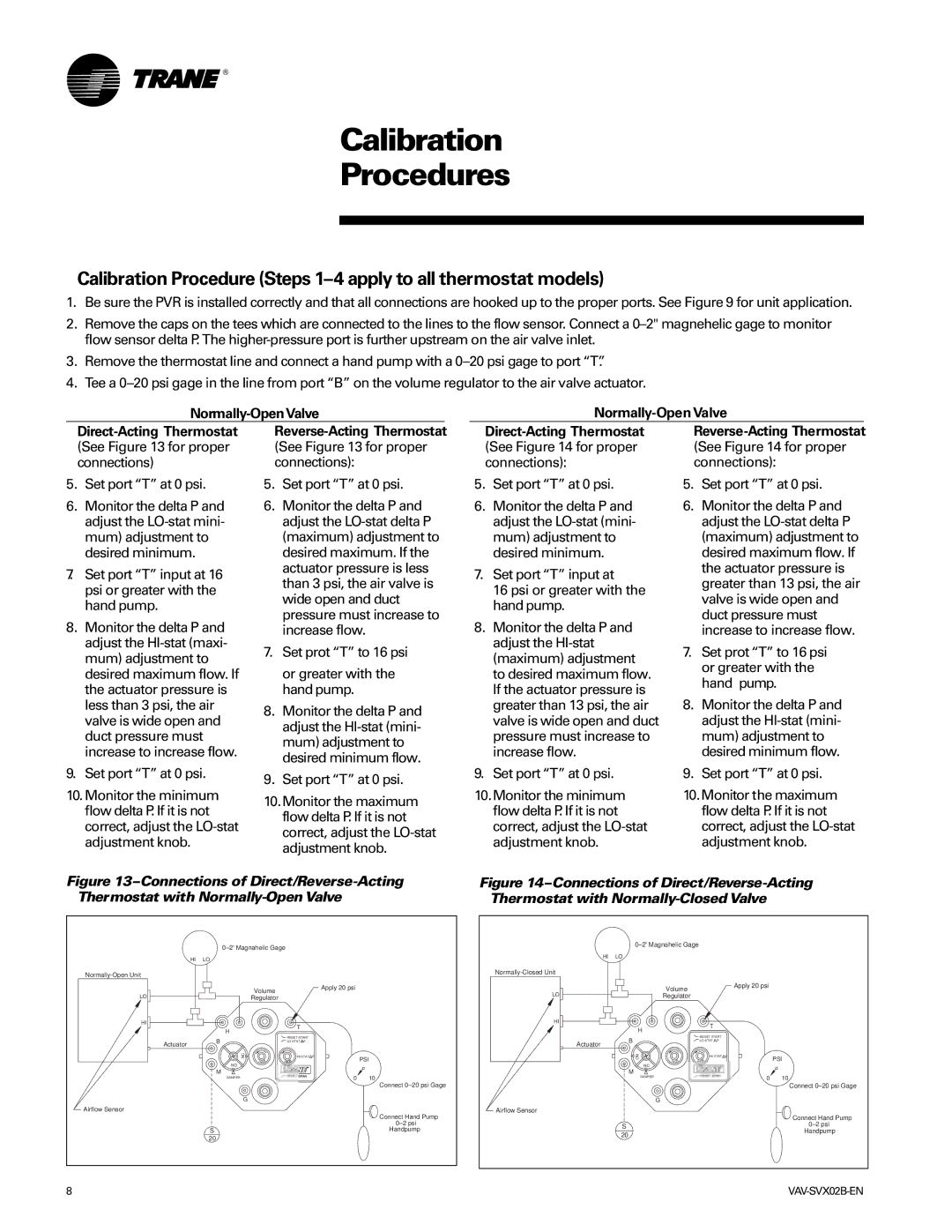

Reverse-Acting Thermostat (See Figure 13 for proper connections):

5.Set port “T” at 0 psi.

6.Monitor the delta P and adjust the

7.Set prot “T” to 16 psi

or greater with the hand pump.

8.Monitor the delta P and adjust the

9.Set port “T” at 0 psi.

10.Monitor the maximum flow delta P. If it is not correct, adjust the

5.Set port “T” at 0 psi.

6.Monitor the delta P and adjust the

7.Set port “T” input at

16 psi or greater with the hand pump.

8.Monitor the delta P and adjust the

9.Set port “T” at 0 psi.

10.Monitor the minimum flow delta P. If it is not correct, adjust the

5.Set port “T” at 0 psi.

6.Monitor the delta P and adjust the

7.Set prot “T” to 16 psi or greater with the hand pump.

8.Monitor the delta P and adjust the

9.Set port “T” at 0 psi.

10.Monitor the maximum flow delta P. If it is not correct, adjust the

Figure | Figure |

Thermostat with | Thermostat with |

0±2© Magnahelic Gage

HI LO

0±2© Magnahelic Gage

HI LO

LO ![]()

![]()

Volume | Apply 20 psi |

Regulator |

|

Normally-Closed Unit

LO ![]()

![]()

Volume

Regulator

Apply 20 psi

HI

T |

H |

HI

H

![]() T

T

Actuator

![]() Airflow Sensor

Airflow Sensor

B | RESET START |

|

LO STAT P |

| |

NC | HI STAT P | PSI |

I C |

| |

NO |

|

|

M | 0 | 10 |

DAMPER | ||

|

Connect 0±20 psi Gage

| G |

| Connect Hand Pump |

| 0±2 psi |

S | Handpump |

20 |

|

Actuator

Airflow Sensor

![]() RESET START

RESET START

B![]() LO STAT

LO STAT ![]() P

P

NO |

| HI STAT P |

I | C | I N R |

NC |

|

|

M |

|

|

DAMPER |

|

|

G

S 20

PSI

0 10

Connect 0±20 psi Gage

![]() Connect Hand Pump

Connect Hand Pump

0±2 psi

Handpump

8 |