Battery Connection

Connect your Inverter/Charger to your batteries using the following procedures:

•Connect DC Wiring: Though your Inverter/Charger is a

the length and gauge of the cabling run- ning from the bat-

tery to the unit. Use the shortest length and largest diameter

cabling (maximum 2/0 gauge) to fit

your Inverter/Charger’s DC Input terminals. Shorter and heavier gauge cabling reduces DC voltage drop and allows for maximum

transfer of current. Your Inverter/Charger is capable of delivering peak wattage at up to 200% of its rated continuous wattage output for brief periods of time. See Specifications page for details. Heavier gauge cabling should be used when continuously operating heavy draw equipment under these conditions. Tighten your Inverter/Charger and battery terminals to approximately 3.5 Newton- meters of torque to create an efficient con- nection and to prevent excessive heating at this connection. Insufficient tightening of the terminals could void your warranty. See Specifications page for Minimum Recommended Cable Sizing Chart.

•Connect Ground: Using a #8 AWG wire or larger directly connect the Main Ground

Lug to the vehicle’s chassis or earth ground. See the Feature Identification section to locate the Main Ground Lug on your specific Inverter/Charger model. All installations must comply with national and local codes and ordinances.

•Connect Fuse: NEC (National Electrical Code) article 551 requires that you connect all of your Inverter/Charger’s positive DC Terminals directly to a

WARNING! • Failure to properly ground your Inverter/Charger to a vehicle’s chassis or earth ground may result in a lethal electrical shock hazard.

•Never attempt to operate your Inverter/Charger by connecting it directly to output from an alternator rather than a battery or battery bank.

•Observe proper polarity with all DC connections.

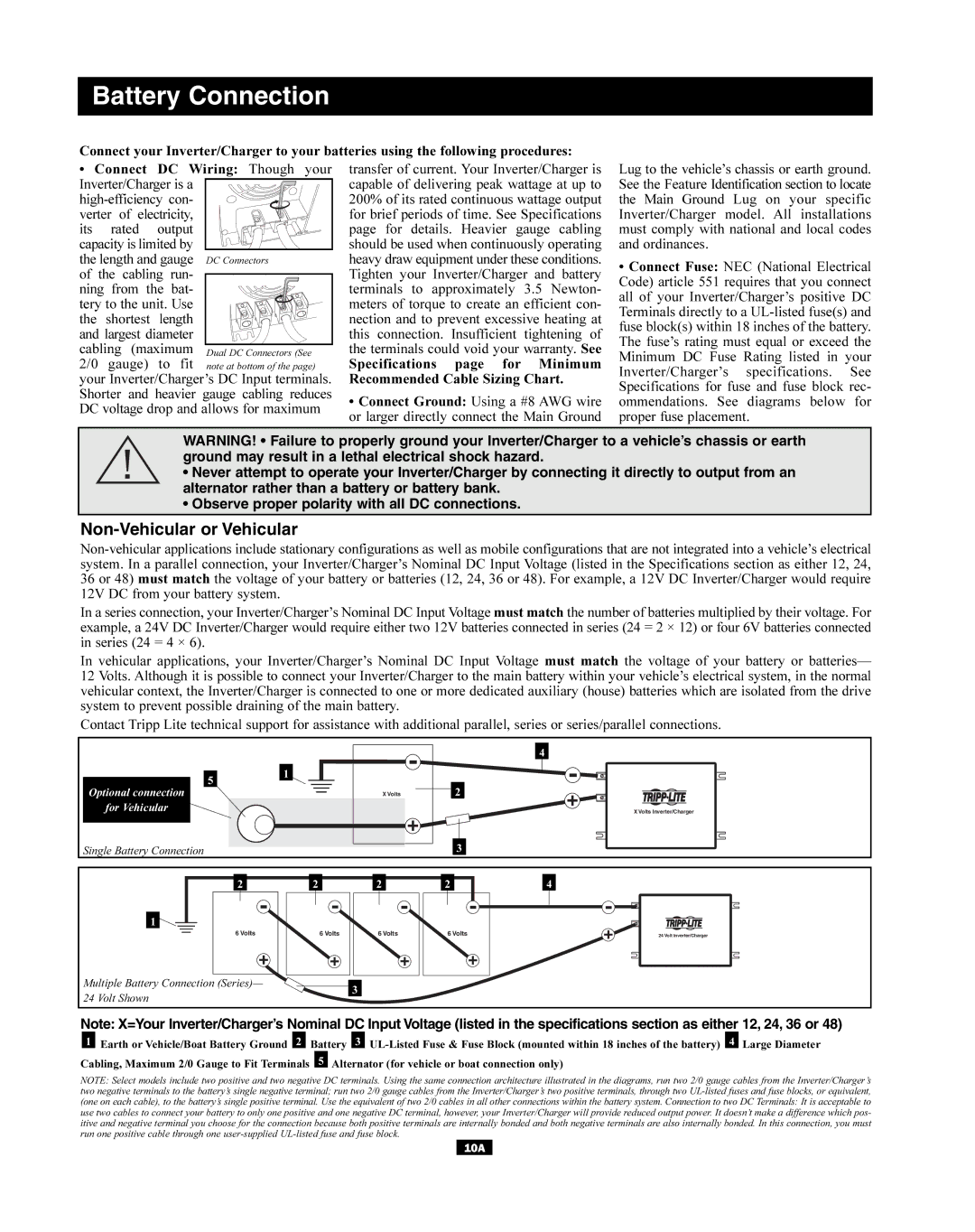

Non-Vehicular or Vehicular

In a series connection, your Inverter/Charger’s Nominal DC Input Voltage must match the number of batteries multiplied by their voltage. For example, a 24V DC Inverter/Charger would require either two 12V batteries connected in series (24 = 2 × 12) or four 6V batteries connected in series (24 = 4 × 6).

In vehicular applications, your Inverter/Charger’s Nominal DC Input Voltage must match the voltage of your battery or batteries— 12 Volts. Although it is possible to connect your Inverter/Charger to the main battery within your vehicle’s electrical system, in the normal vehicular context, the Inverter/Charger is connected to one or more dedicated auxiliary (house) batteries which are isolated from the drive system to prevent possible draining of the main battery.

Contact Tripp Lite technical support for assistance with additional parallel, series or series/parallel connections.

5

Optional connection

for Vehicular

Single Battery Connection

1

X Volts

4

2

X Volts Inverter/Charger

3

2

1 ![]()

6 Volts

Multiple Battery Connection (Series)— 24 Volt Shown

2 2

6 Volts | 6 Volts |

3

2

6 Volts

4

24 Volt Inverter/Charger

Note: X=Your Inverter/Charger’s Nominal DC Input Voltage (listed in the specifications section as either 12, 24, 36 or 48)

1Earth or Vehicle/Boat Battery Ground 2 Battery 3

Cabling, Maximum 2/0 Gauge to Fit Terminals 5 Alternator (for vehicle or boat connection only)

NOTE: Select models include two positive and two negative DC terminals. Using the same connection architecture illustrated in the diagrams, run two 2/0 gauge cables from the Inverter/Charger’s two negative terminals to the battery’s single negative terminal; run two 2/0 gauge cables from the Inverter/Charger’s two positive terminals, through two

10A