.

Shift

ArmFriction

Wheel

Hex Shaft

Bearing

Sprocket

|

| Figure 25 |

Figure 23 | NOTE: | If you placed plastic under the gas cap, be |

|

certain to remove it.

| Plate |

Friction | Screw |

Wheel |

Rubber ![]()

Figure 24

9.Reassemble new friction wheel rubber to the friction wheel assembly, tightening the four screws in rotation and with equal force. See Figure 24.

IMPORTANT: Assemble the rubber on the friction wheel equally for proper functioning.

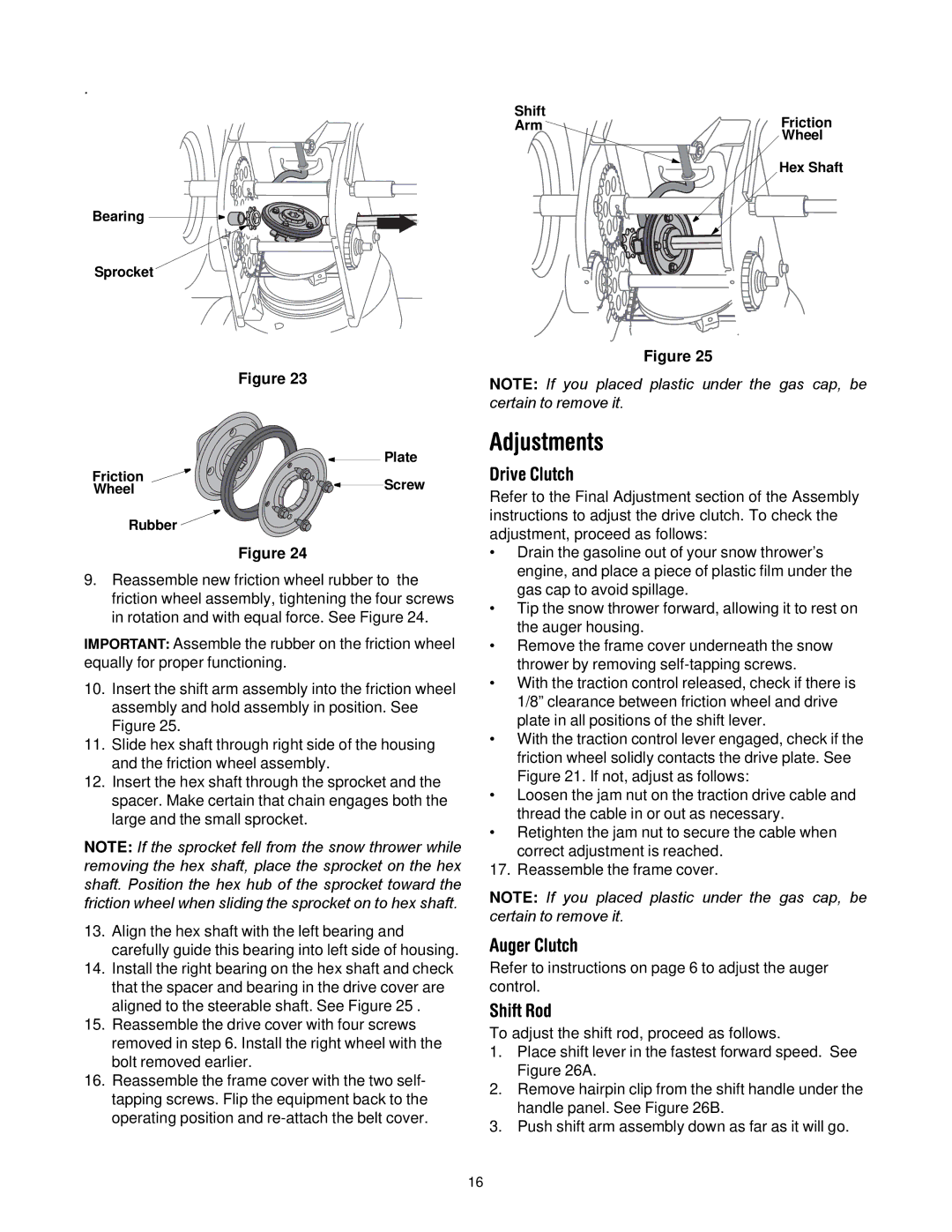

10.Insert the shift arm assembly into the friction wheel assembly and hold assembly in position. See Figure 25.

11.Slide hex shaft through right side of the housing and the friction wheel assembly.

12.Insert the hex shaft through the sprocket and the spacer. Make certain that chain engages both the large and the small sprocket.

NOTE: If the sprocket fell from the snow thrower while removing the hex shaft, place the sprocket on the hex shaft. Position the hex hub of the sprocket toward the friction wheel when sliding the sprocket on to hex shaft.

13.Align the hex shaft with the left bearing and carefully guide this bearing into left side of housing.

14.Install the right bearing on the hex shaft and check that the spacer and bearing in the drive cover are aligned to the steerable shaft. See Figure 25 .

15.Reassemble the drive cover with four screws removed in step 6. Install the right wheel with the bolt removed earlier.

16.Reassemble the frame cover with the two self- tapping screws. Flip the equipment back to the operating position and

Adjustments

Drive Clutch

Refer to the Final Adjustment section of the Assembly instructions to adjust the drive clutch. To check the adjustment, proceed as follows:

•Drain the gasoline out of your snow thrower’s engine, and place a piece of plastic film under the gas cap to avoid spillage.

•Tip the snow thrower forward, allowing it to rest on the auger housing.

•Remove the frame cover underneath the snow thrower by removing

•With the traction control released, check if there is 1/8” clearance between friction wheel and drive plate in all positions of the shift lever.

•With the traction control lever engaged, check if the friction wheel solidly contacts the drive plate. See Figure 21. If not, adjust as follows:

•Loosen the jam nut on the traction drive cable and thread the cable in or out as necessary.

•Retighten the jam nut to secure the cable when

correct adjustment is reached.

17. Reassemble the frame cover.

NOTE: If you placed plastic under the gas cap, be certain to remove it.

Auger Clutch

Refer to instructions on page 6 to adjust the auger control.

Shift Rod

To adjust the shift rod, proceed as follows.

1.Place shift lever in the fastest forward speed. See Figure 26A.

2.Remove hairpin clip from the shift handle under the handle panel. See Figure 26B.

3.Push shift arm assembly down as far as it will go.

16