Section

5

Maintenance

11

WARNING

Before inspecting, cleaning or servicing the machine, shut off engine, discon- nect spark plug wire, and make sure that all moving parts have come to a com- plete stop. Remove ignition key on electric start models.

Failure to follow these instructions can result in personal injury or property damage.

NOTE: LEFT and RIGHT sides of unit are as viewed from operator’s position behind the handlebars.

REQUIRED MAINTENANCE SCHEDULE

REQUIRED MAINTENANCE | BEFORE | EVERY | EVERY | EVERY | AS |

|

EACH | 5 | 25 | 100 | NOTED | ||

| USE | HOURS | HOURS | HOURS |

|

|

|

|

|

|

|

|

|

CHECK ENGINE OIL LEVEL | • | • |

|

|

|

|

|

|

|

|

|

|

|

CHECK TRIMMER LINES | • |

|

|

| 1 |

|

|

|

|

|

|

|

|

CHECK TRIMMER HEAD ENGAGEMENT | • |

|

|

|

|

|

|

|

|

|

|

|

|

MACHINE CLEANING | • |

|

|

| 3 |

|

|

|

|

|

|

|

|

CHECK NUTS AND BOLTS | • |

|

|

|

|

|

|

|

|

|

|

|

|

CHANGE ENGINE OIL |

|

| • |

| 2, 5 |

|

|

|

|

|

|

|

|

SERVICE AIR FILTER SYSTEM |

|

| • |

| 5 |

|

|

|

|

|

|

|

|

CLEAN UNDER DECK |

|

| • |

|

|

|

|

|

|

|

|

|

|

GENERAL LUBRICATION |

|

| • |

|

|

|

|

|

|

|

|

|

|

INSPECT DRIVE BELT |

|

|

| • |

|

|

|

|

|

|

|

|

|

CLEAN ENGINE | • |

|

|

| 4 |

|

|

|

|

|

|

|

|

CHECK WEAR CUP |

| • |

|

| 6 |

|

|

|

|

|

|

|

|

Chart

NOTE 1 – New line replacement is suggested when old line is 50% or less of original length. NOTE 2 – Change oil after first two hours of new operation; thereafter every 25 hours. NOTE 3 – Clean daily if used in extremely dusty/dirty conditions (see engine manual).

NOTE 4 – Clean before using machine and at each fuel refill.

NOTE 5 – Service more often if used in extremely dusty or dirty conditions (see engine manual).

NOTE 6 – Replace when severe gouges exist on bottom surface.

ADJUSTING TRIMMER

HEAD ENGAGEMENT

The tension on the drive belt must be correct for proper operation of the trimmer head. If the tension is correct, the trimmer head will rotate when the Trimmer Head Control Bail is pulled back against the handlebar.

A loose or worn drive belt will cause the trimmer head to move slowly, or not at all, when the control bail is engaged (belt squealing may also be noticeable).

If the belt tension is too tight, the trimmer head may rotate before the con- trol bail is engaged, or when there is no free play in the control bail. To adjust belt tension:

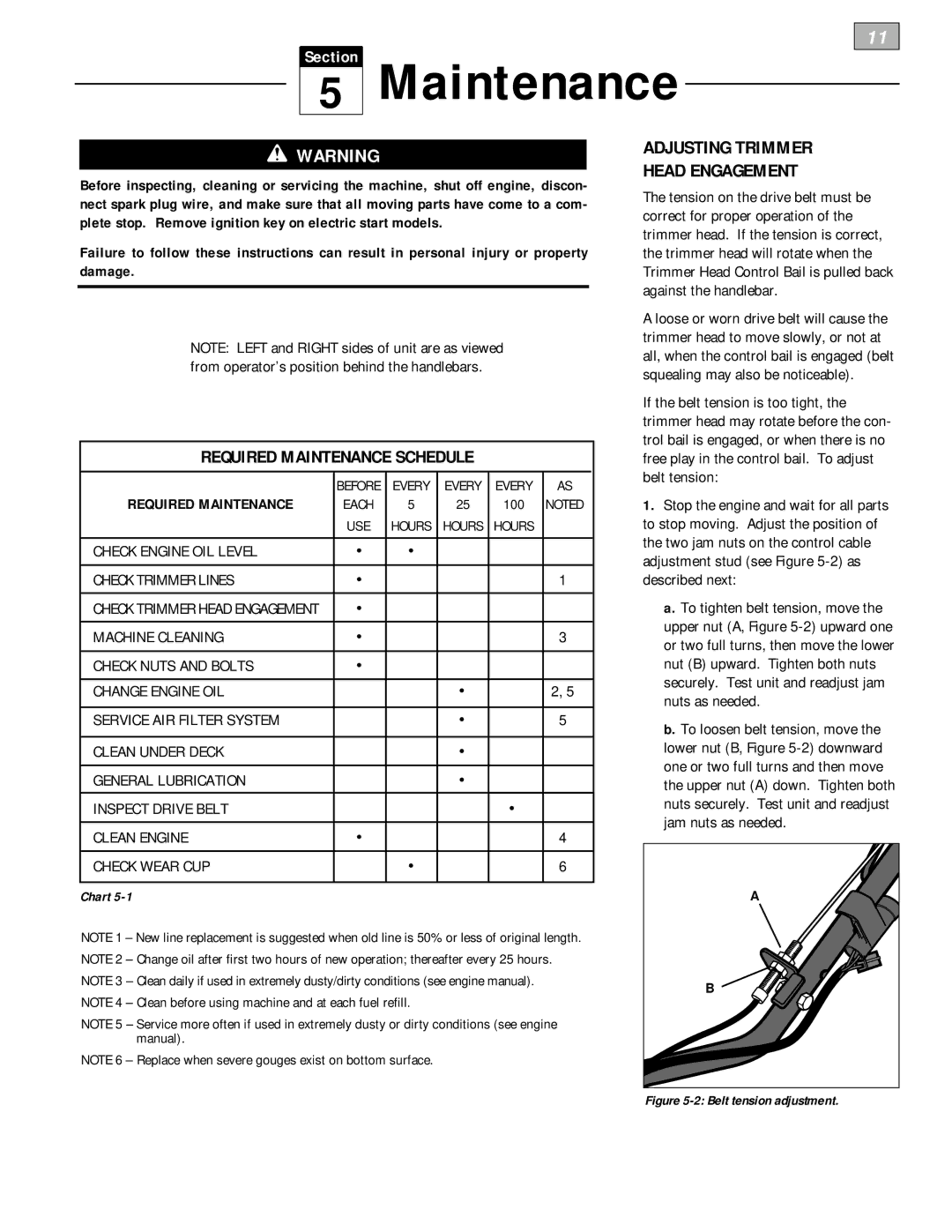

1.Stop the engine and wait for all parts to stop moving. Adjust the position of the two jam nuts on the control cable adjustment stud (see Figure

a.To tighten belt tension, move the upper nut (A, Figure

b.To loosen belt tension, move the lower nut (B, Figure

A

B