n

Assembly

WARNING

To prevent personal injury or property damage, do not start the engine until all assembly steps are complete and you have read and understand the

safety and operating instruc- tions in this manual.

Introduction

Carefullyfollow these assembly steps to correctly prepareyour tiller for use. It is recommendedthat you read this Section in its entirety before beginning assembly. NOTE: Enginesyles vary by model. The engineon your tiller may appeardiffer- ently than those shown in illustrations and Figuresthroughout this manual.

Inspectunit

Inspectthe unit and carton for damage immediately after delivery. Contactthe carrier (trucking company) if you find or suspect damage. Inform them of the damageand request instructions for filing aclaim. To protect your rights, put your claim in writing and mail acopy to the

NOTE:Becareful not to severely bendany of the control cables on the unit.

3.Removeall unassembled parts and the separatehardware bagfrom the carton. Checkthat you havethe items

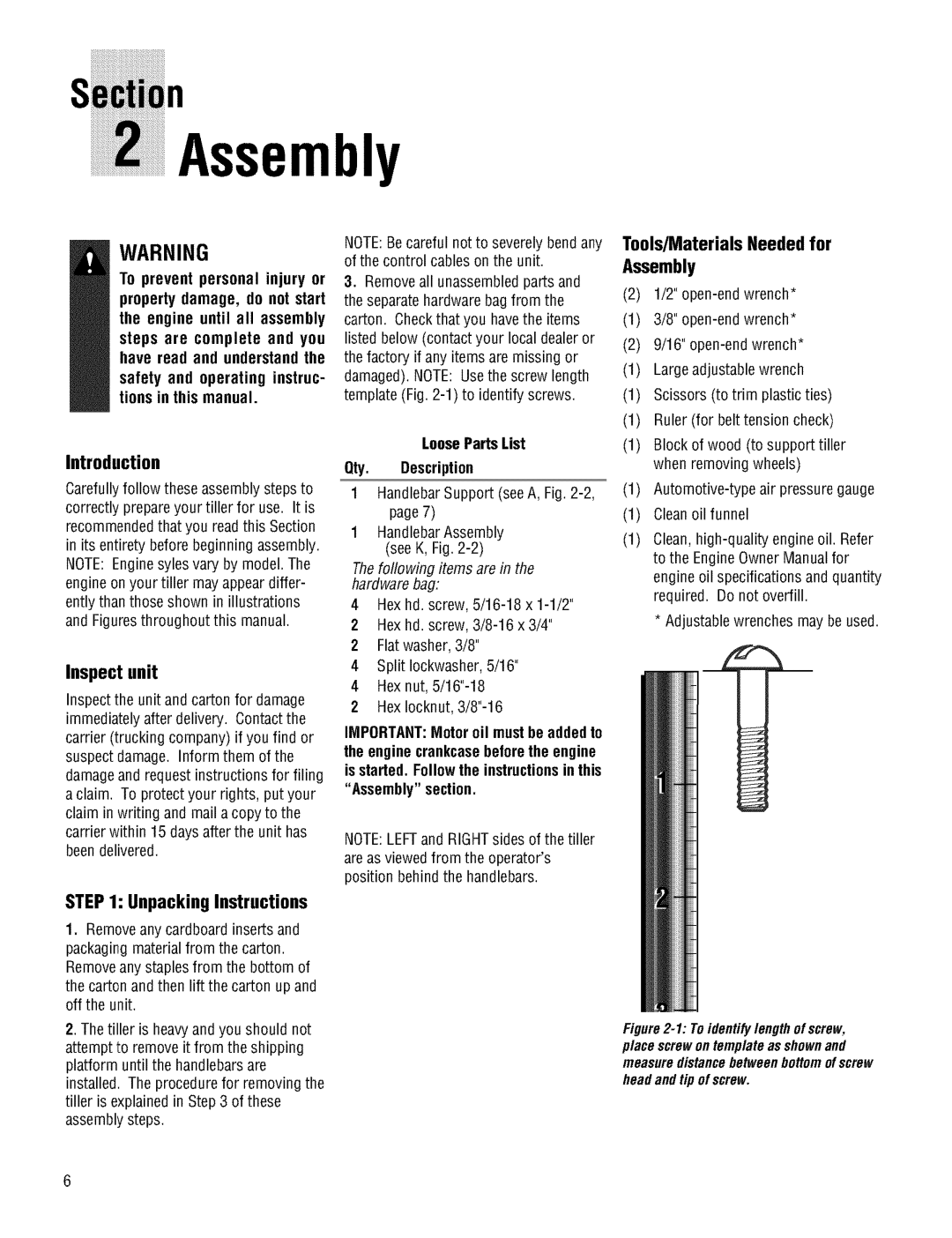

listed below (contact your local dealeror the factory if any items are missing or damaged). NOTE: Usethe screw length template (Fig.

LooseParts List

Qty. Description

1HandlebarSupport (seeA, Fig.

1HandlebarAssembly (see K, Fig.

Thefo//owing itemsare in the hardware bag:

4Hexhd. screw,

2Hexhd. screw,

2Flatwasher, 3/8"

4Split Iockwasher,5/16"

4Hexnut,

2HexIocknut,

IMPORTANT:Motor oil mustbe addedto

the engine crankcasebeforethe engine is started. Followthe instructionsin this

"Assembly" section.

Tools/MaterialsNeededfor

Assembly

(2)1/2"

(1)3/8"

(2)9/16"

(1)Largeadjustable wrench

(1)Scissors (to trim plastic ties)

(1)Ruler (for belt tension check)

(1)Block of wood (to support tiller when removing wheels)

(1)

(1)Cleanoil funnel

(1)

*Adjustable wrenches may be used.

carrier within 15 days after the unit has beendelivered.

NOTE:LEFTand RIGHTsides of the tiller are as viewed from the operator's position behindthe handlebars.

STEP 1: Unpacking Instructions

1.Removeany cardboard inserts and packagingmaterial from the carton. Removeany staples from the bottom of the carton andthen lift the carton up and off the unit.

2.The tiller is heavyand you should not attempt to remove it from the shipping platform until the handlebarsare installed. The procedure for removing the tiller is explained in Step 3 of these assemblysteps.