ANSI Z83.7-2000, CSA 2.14-2000 specifications

Vermont Castings CSA 2.14-2000 and ANSI Z83.7-2000 are key standards in the world of gas appliances, particularly for those using charcoal, propane, or natural gas. These standards provide guidelines aimed at ensuring safety, efficiency, and performance in a variety of heating equipment, including fireplaces, stoves, and other appliances.The Vermont Castings CSA 2.14-2000 standard pertains to the performance and construction criteria for residential gas appliances. A significant feature of this standard is its emphasis on safety mechanisms designed to prevent gas leaks and ensure reliable ignition. This ensures that users are protected from the risks associated with gas-based heating. The standard also outlines the requirements for proper ventilation, which is crucial for any gas appliance to operate effectively without the risk of harmful emissions.

Another notable aspect of the CSA 2.14-2000 standard is its focus on efficiency. It mandates strict guidelines for energy use, which encourages manufacturers to innovate and create appliances that not only meet consumer heating needs but also do so in an environmentally friendly manner. Appliances compliant with this standard are likely to embody technologies that optimize fuel utilization and reduce emissions, contributing to a more sustainable heating option for consumers.

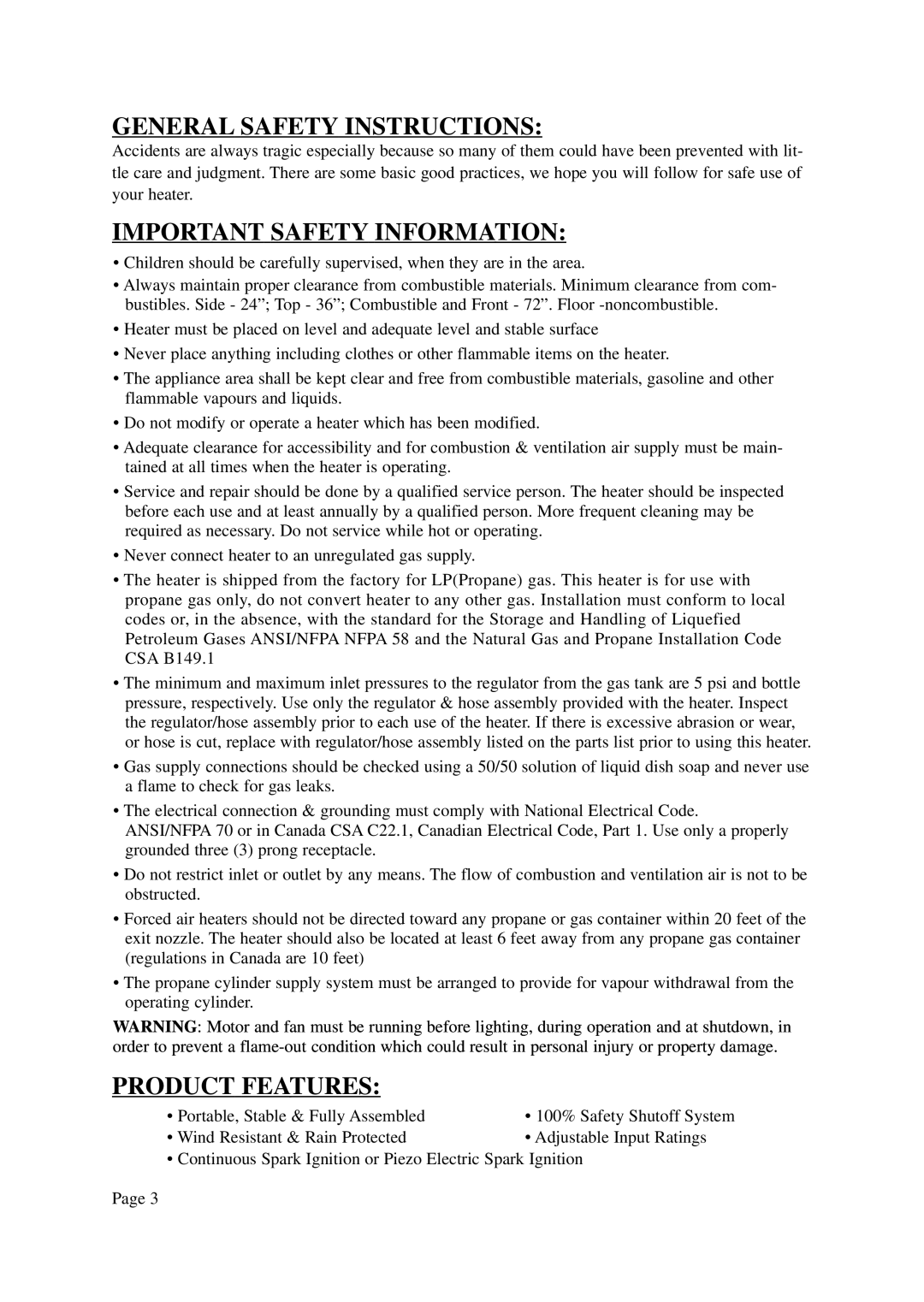

ANSI Z83.7-2000 complements the CSA 2.14-2000 standard by addressing the safety and construction requirements specific to gas-fired appliances. This standard sets forth comprehensive design criteria that prevent the occurrence of hazardous situations such as accidental fires or carbon monoxide poisoning. It emphasizes the importance of utilizing high-quality materials in appliance construction, ensuring durability and safety over an extended life cycle.

One of the key technologies addressed in these standards is ignition systems. Advanced ignition mechanisms, such as electronic spark ignitions and pilot light systems, are covered to ensure reliable and secure operations. The standards also stress the importance of user-friendly features, ensuring that consumers can operate the appliances with ease while adhering to best safety practices.

In conclusion, Vermont Castings CSA 2.14-2000 and ANSI Z83.7-2000 set industry standards that prioritize safety, efficiency, and user experience in gas-fired appliances. By ensuring compliance with these guidelines, manufacturers are encouraged to pursue innovations that enhance the performance and environmental responsibility of their products, thereby benefiting consumers and the planet alike.