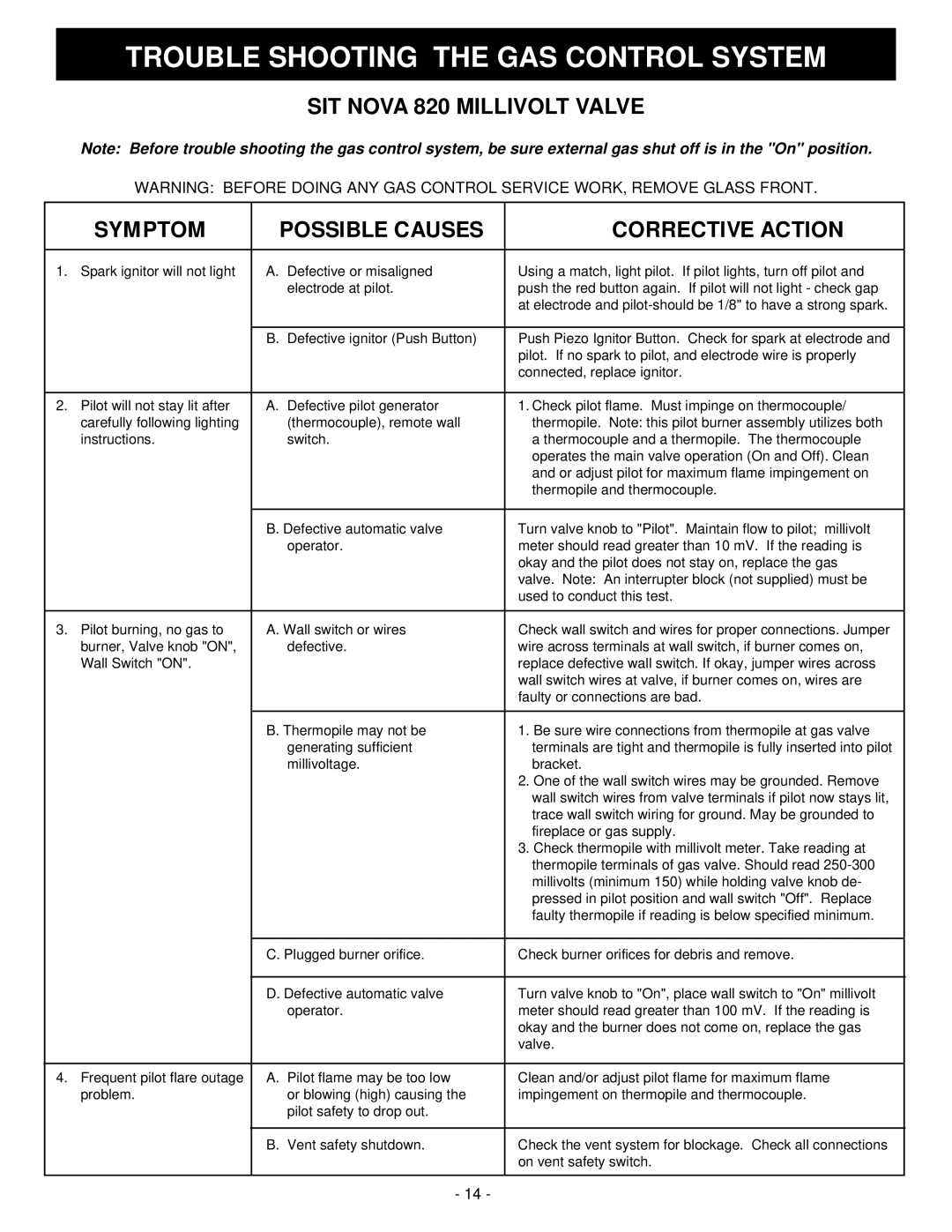

TROUBLE SHOOTING THE GAS CONTROL SYSTEM

SIT NOVA 820 MILLIVOLT VALVE

Note: Before trouble shooting the gas control system, be sure external gas shut off is in the "On" position.

WARNING: BEFORE DOING ANY GAS CONTROL SERVICE WORK, REMOVE GLASS FRONT.

SYMPTOM | POSSIBLE CAUSES | CORRECTIVE ACTION | |

|

|

|

|

1. Spark ignitor will not light | A. Defective or misaligned | Using a match, light pilot. If pilot lights, turn off pilot and | |

|

| electrode at pilot. | push the red button again. If pilot will not light - check gap |

|

|

| at electrode and |

|

|

|

|

|

| B. Defective ignitor (Push Button) | Push Piezo Ignitor Button. Check for spark at electrode and |

|

|

| pilot. If no spark to pilot, and electrode wire is properly |

|

|

| connected, replace ignitor. |

|

|

|

|

2. Pilot will not stay lit after | A. Defective pilot generator | 1. Check pilot flame. Must impinge on thermocouple/ | |

carefully following lighting | (thermocouple), remote wall | thermopile. Note: this pilot burner assembly utilizes both | |

instructions. | switch. | a thermocouple and a thermopile. The thermocouple | |

|

|

| operates the main valve operation (On and Off). Clean |

|

|

| and or adjust pilot for maximum flame impingement on |

|

|

| thermopile and thermocouple. |

|

|

|

|

|

| B. Defective automatic valve | Turn valve knob to "Pilot". Maintain flow to pilot; millivolt |

|

| operator. | meter should read greater than 10 mV. If the reading is |

|

|

| okay and the pilot does not stay on, replace the gas |

|

|

| valve. Note: An interrupter block (not supplied) must be |

|

|

| used to conduct this test. |

|

|

|

|

3. Pilot burning, no gas to | A. Wall switch or wires | Check wall switch and wires for proper connections. Jumper | |

burner, Valve knob "ON", | defective. | wire across terminals at wall switch, if burner comes on, | |

Wall Switch "ON". |

| replace defective wall switch. If okay, jumper wires across | |

|

|

| wall switch wires at valve, if burner comes on, wires are |

|

|

| faulty or connections are bad. |

|

|

|

|

|

| B. Thermopile may not be | 1. Be sure wire connections from thermopile at gas valve |

|

| generating sufficient | terminals are tight and thermopile is fully inserted into pilot |

|

| millivoltage. | bracket. |

|

|

| 2. One of the wall switch wires may be grounded. Remove |

|

|

| wall switch wires from valve terminals if pilot now stays lit, |

|

|

| trace wall switch wiring for ground. May be grounded to |

|

|

| fireplace or gas supply. |

|

|

| 3. Check thermopile with millivolt meter. Take reading at |

|

|

| thermopile terminals of gas valve. Should read |

|

|

| millivolts (minimum 150) while holding valve knob de- |

|

|

| pressed in pilot position and wall switch "Off". Replace |

|

|

| faulty thermopile if reading is below specified minimum. |

|

|

|

|

|

| C. Plugged burner orifice. | Check burner orifices for debris and remove. |

|

|

|

|

|

| D. Defective automatic valve | Turn valve knob to "On", place wall switch to "On" millivolt |

|

| operator. | meter should read greater than 100 mV. If the reading is |

|

|

| okay and the burner does not come on, replace the gas |

|

|

| valve. |

|

|

|

|

4. Frequent pilot flare outage | A. Pilot flame may be too low | Clean and/or adjust pilot flame for maximum flame | |

problem. | or blowing (high) causing the | impingement on thermopile and thermocouple. | |

|

| pilot safety to drop out. |

|

|

|

|

|

|

| B. Vent safety shutdown. | Check the vent system for blockage. Check all connections |

|

|

| on vent safety switch. |

|

|

|

|

- 14 -