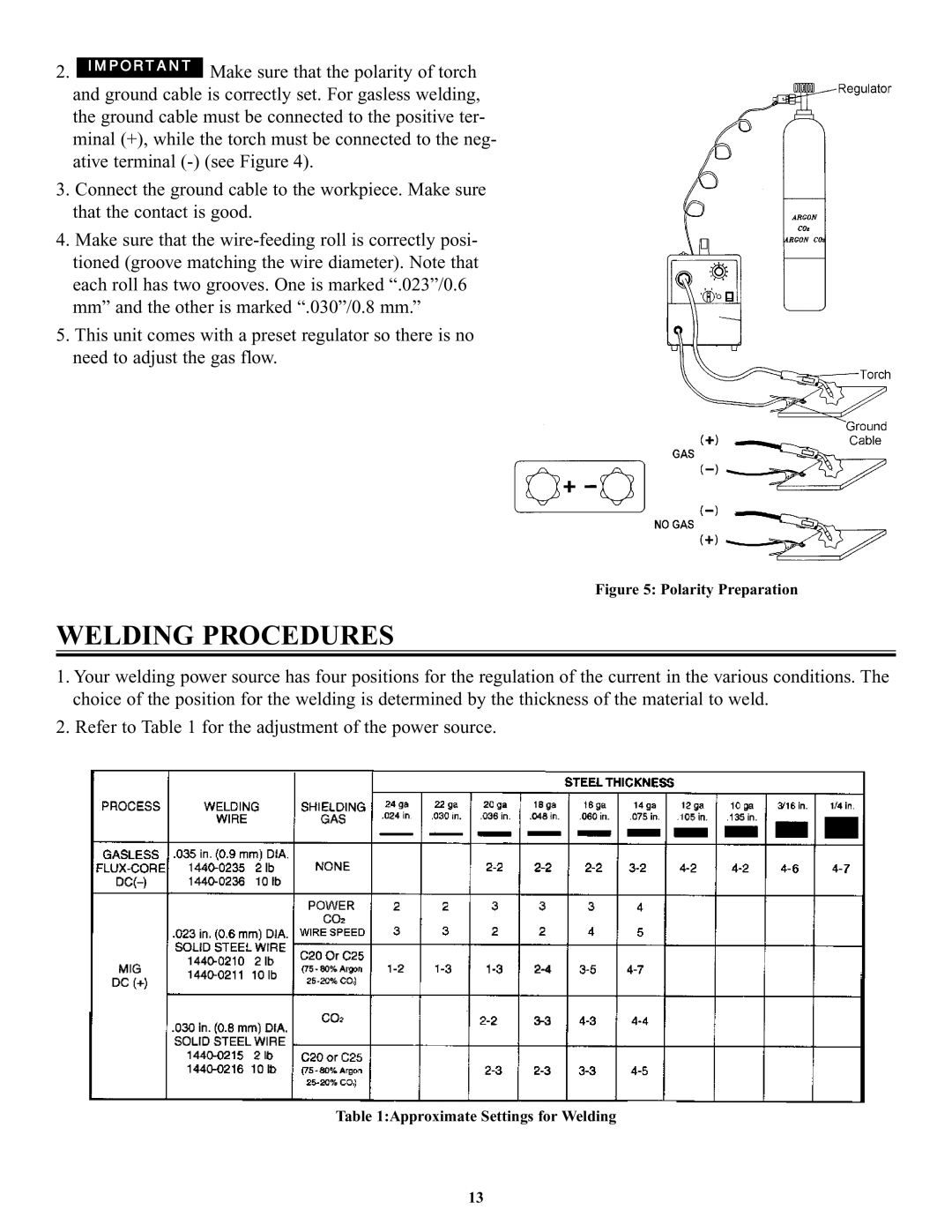

2. IMPORTANT Make sure that the polarity of torch and ground cable is correctly set. For gasless welding, the ground cable must be connected to the positive ter- minal (+), while the torch must be connected to the neg- ative terminal

3.Connect the ground cable to the workpiece. Make sure that the contact is good.

4.Make sure that the

5.This unit comes with a preset regulator so there is no need to adjust the gas flow.

Figure 5: Polarity Preparation

WELDING PROCEDURES

1.Your welding power source has four positions for the regulation of the current in the various conditions. The choice of the position for the welding is determined by the thickness of the material to weld.

2.Refer to Table 1 for the adjustment of the power source.

Table 1:Approximate Settings for Welding

13