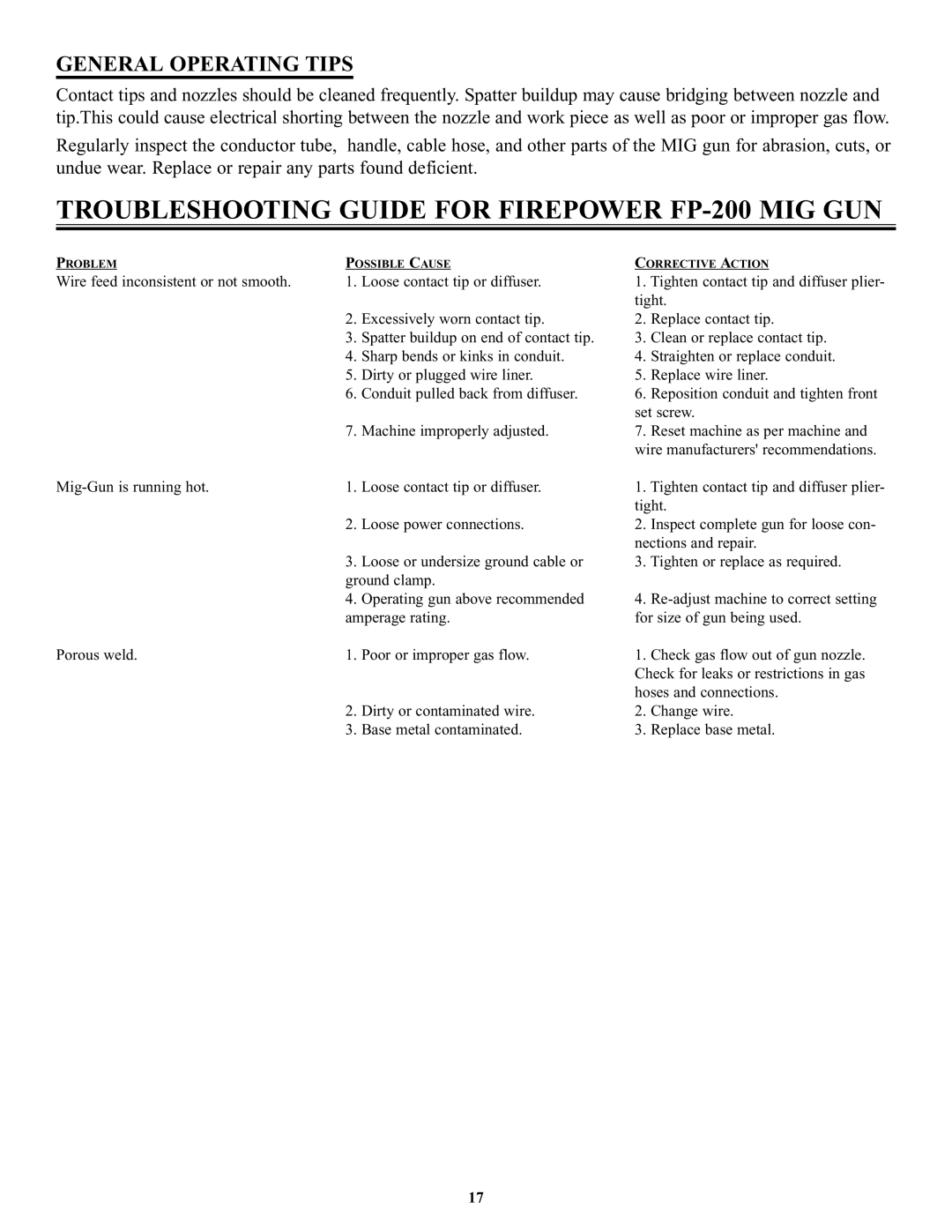

GENERAL OPERATING TIPS

Contact tips and nozzles should be cleaned frequently. Spatter buildup may cause bridging between nozzle and tip.This could cause electrical shorting between the nozzle and work piece as well as poor or improper gas flow.

Regularly inspect the conductor tube, handle, cable hose, and other parts of the MIG gun for abrasion, cuts, or undue wear. Replace or repair any parts found deficient.

TROUBLESHOOTING GUIDE FOR FIREPOWER FP-200 MIG GUN

PROBLEM

Wire feed inconsistent or not smooth.

Porous weld.

POSSIBLE CAUSE

1.Loose contact tip or diffuser.

2.Excessively worn contact tip.

3.Spatter buildup on end of contact tip.

4.Sharp bends or kinks in conduit.

5.Dirty or plugged wire liner.

6.Conduit pulled back from diffuser.

7.Machine improperly adjusted.

1.Loose contact tip or diffuser.

2.Loose power connections.

3.Loose or undersize ground cable or ground clamp.

4.Operating gun above recommended amperage rating.

1.Poor or improper gas flow.

2.Dirty or contaminated wire.

3.Base metal contaminated.

CORRECTIVE ACTION

1.Tighten contact tip and diffuser plier- tight.

2.Replace contact tip.

3.Clean or replace contact tip.

4.Straighten or replace conduit.

5.Replace wire liner.

6.Reposition conduit and tighten front set screw.

7.Reset machine as per machine and wire manufacturers' recommendations.

1.Tighten contact tip and diffuser plier- tight.

2.Inspect complete gun for loose con- nections and repair.

3.Tighten or replace as required.

4.

1.Check gas flow out of gun nozzle. Check for leaks or restrictions in gas hoses and connections.

2.Change wire.

3.Replace base metal.

17