G900 MOTOR GRADERS

FROM THE GROUND UP

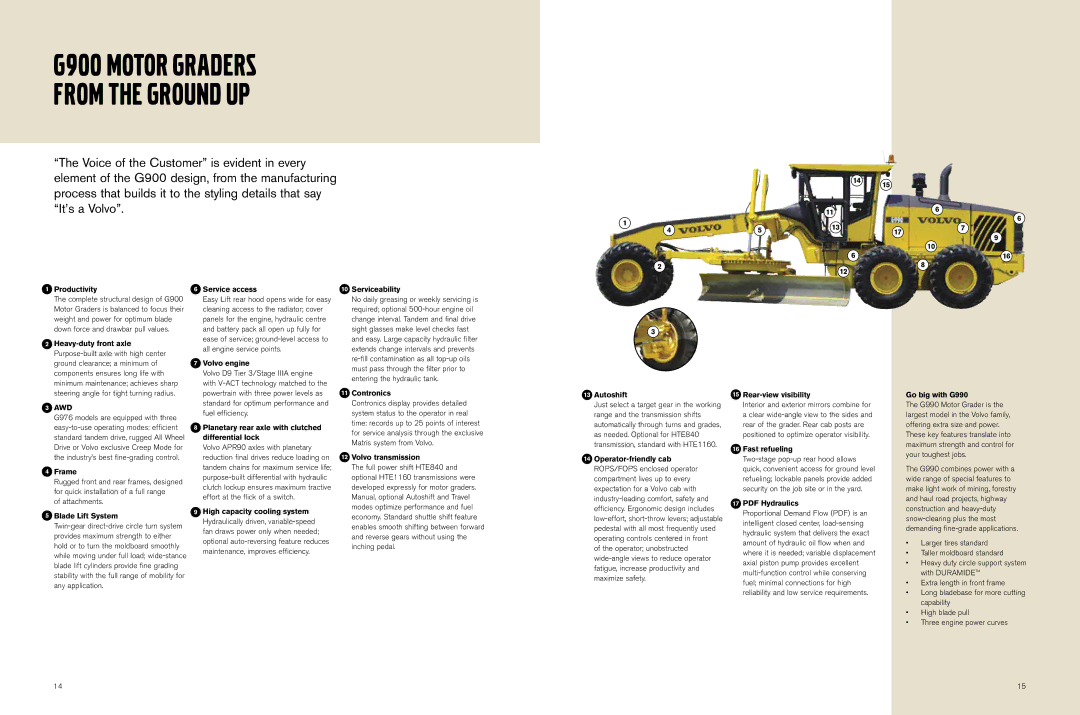

“The Voice of the Customer” is evident in every element of the G900 design, from the manufacturing process that builds it to the styling details that say “It’s a Volvo”.

|

| 14 | 15 |

| |

|

|

|

| ||

|

| 11 |

| 6 | |

|

|

| 6 | ||

1 |

|

|

| ||

| 13 |

| 7 | ||

4 | 5 | 17 | |||

| 9 | ||||

|

|

|

| ||

|

|

|

| 10 | |

|

| 6 |

| 16 | |

2 |

| 12 |

| 8 | |

|

|

|

|

1Productivity

The complete structural design of G900 Motor Graders is balanced to focus their weight and power for optimum blade down force and drawbar pull values.

6 Service access |

Easy Lift rear hood opens wide for easy |

cleaning access to the radiator; cover |

panels for the engine, hydraulic centre |

and battery pack all open up fully for |

ease of service; |

10 Serviceability |

No daily greasing or weekly servicing is |

required; optional |

change interval. Tandem and final drive |

sight glasses make level checks fast |

and easy. Large capacity hydraulic filter |

3

2

3AWD

G976 models are equipped with three

4Frame

Rugged front and rear frames, designed for quick installation of a full range

of attachments.

5Blade Lift System

all engine service points. |

7Volvo engine

Volvo D9 Tier 3/Stage IIIA engine with

8Planetary rear axle with clutched differential lock

Volvo APR90 axles with planetary reduction final drives reduce loading on tandem chains for maximum service life;

9High capacity cooling system Hydraulically driven,

extends change intervals and prevents |

must pass through the filter prior to |

entering the hydraulic tank. |

11 Contronics |

Contronics display provides detailed |

system status to the operator in real |

time: records up to 25 points of interest |

for service analysis through the exclusive |

Matris system from Volvo. |

12 Volvo transmission |

The full power shift HTE840 and |

optional HTE1160 transmissions were |

developed expressly for motor graders. |

Manual, optional Autoshift and Travel |

modes optimize performance and fuel |

economy. Standard shuttle shift feature |

enables smooth shifting between forward |

and reverse gears without using the |

inching pedal. |

13Autoshift

Just select a target gear in the working range and the transmission shifts automatically through turns and grades, as needed. Optional for HTE840 transmission, standard with HTE1160.

14

of the operator; unobstructed

15Rear-view visibility

Interior and exterior mirrors combine for a clear

16Fast refueling

17PDF Hydraulics

Proportional Demand Flow (PDF) is an intelligent closed center,

Go big with G990

The G990 Motor Grader is the largest model in the Volvo family, offering extra size and power. These key features translate into maximum strength and control for your toughest jobs.

The G990 combines power with a wide range of special features to make light work of mining, forestry and haul road projects, highway construction and

•Larger tires standard

•Taller moldboard standard

•Heavy duty circle support system with DURAMIDETM

•Extra length in front frame

•Long bladebase for more cutting capability

•High blade pull

•Three engine power curves

14 | 15 |