Mounting surface | Center bearing | |

bracket | ||

| ||

Vertical line |

| |

(2) 5/16” x |

| |

Lag screws |

| |

Horizontal line |

| |

| (1) 5/16” X 2” or (1) 5/16” x | |

|

16 | Spring Assembly | |

Tools: Step Ladder | ||

|

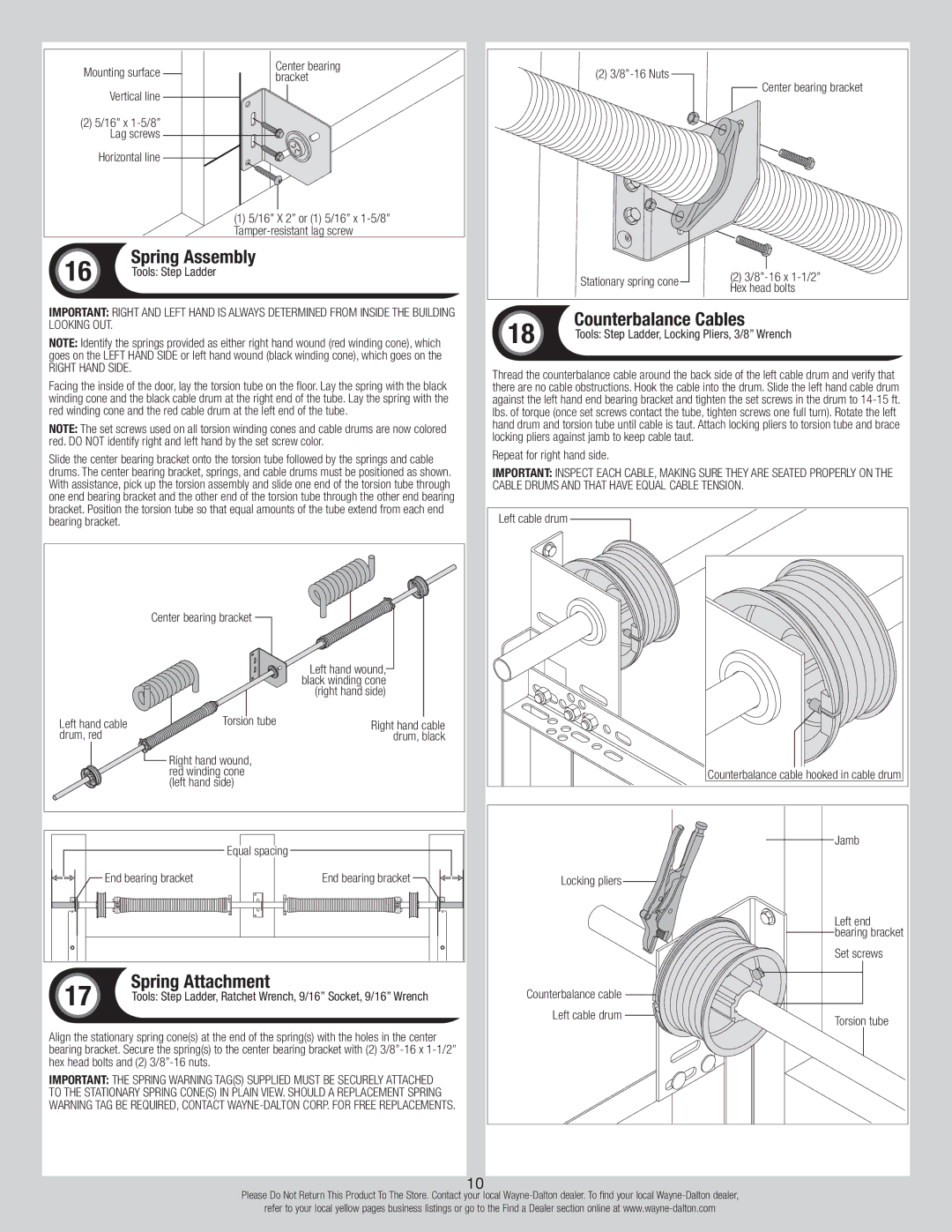

IMPORTANT: Right and left hand is always determined from inside the building looking out.

NOTE: Identify the springs provided as either right hand wound (red winding cone), which goes on the LEFT HAND SIDE or left hand wound (black winding cone), which goes on the

RIGHT HAND SIDE.

Facing the inside of the door, lay the torsion tube on the floor. Lay the spring with the black winding cone and the black cable drum at the right end of the tube. Lay the spring with the red winding cone and the red cable drum at the left end of the tube.

NOTE: The set screws used on all torsion winding cones and cable drums are now colored red. DO NOT identify right and left hand by the set screw color.

Slide the center bearing bracket onto the torsion tube followed by the springs and cable drums. The center bearing bracket, springs, and cable drums must be positioned as shown. With assistance, pick up the torsion assembly and slide one end of the torsion tube through one end bearing bracket and the other end of the torsion tube through the other end bearing bracket. Position the torsion tube so that equal amounts of the tube extend from each end bearing bracket.

(2)

Center bearing bracket

|

|

|

|

|

|

|

|

Stationary spring cone |

| (2) | |

| Hex head bolts | ||

|

| ||

18 | Counterbalance Cables | |

Tools: Step Ladder, Locking Pliers, 3/8” Wrench | ||

|

Thread the counterbalance cable around the back side of the left cable drum and verify that there are no cable obstructions. Hook the cable into the drum. Slide the left hand cable drum against the left hand end bearing bracket and tighten the set screws in the drum to

Repeat for right hand side.

IMPORTANT: Inspect each cable, making sure they are seated properly on the cable drums and that have equal cable tension.

Left cable drum |

Left hand cable drum, red

Center bearing bracket

Torsion tube

![]() Right hand wound, red winding cone (left hand side)

Right hand wound, red winding cone (left hand side)

Left hand wound, black winding cone (right hand side)

Right hand cable drum, black

Counterbalance cable hooked in cable drum |

| Equal spacing |

End bearing bracket | End bearing bracket |

17 | Spring Attachment | |

Tools: Step Ladder, Ratchet Wrench, 9/16” Socket, 9/16” Wrench | ||

|

Align the stationary spring cone(s) at the end of the spring(s) with the holes in the center bearing bracket. Secure the spring(s) to the center bearing bracket with (2)

IMPORTANT: The spring warning tag(s) supplied must be securely attached to the stationary spring cone(s) in plain view. Should a replacement spring warning tag be required, contact

Jamb |

Locking pliers

Left end bearing bracket

Set screws

Counterbalance cable |

|

Left cable drum | Torsion tube |

|

10

Please Do Not Return This Product To The Store. Contact your local

refer to your local yellow pages business listings or go to the Find a Dealer section online at