PFG Series 7

Section I: Installation

Combustion air and ventilation openings

Combustion air and ventilation openings must comply with Sec- tion 5.3, Air for Combustion and Ventilation, of National Fuel Gas Code ANSI

Provide adequate combustion and ventilation air to:

•Ensure proper combustion

•Reduce risk or severe personal injury or death from flue gas spillage and carbon monoxide emissions.

Do not install an exhaust fan in the boiler room.

Boiler installation must ensure sufficient openings in building and boiler room to provide adequate combustion air and ventila- tion. Consider construction tightness of building when deciding whether additional outside openings may be needed.

Older buildings with

New construction or remodeled buildings are most often built tighter. Windows and doors are weather stripped, vapor barriers are used and openings in walls are caulked. As a result, such tight construction is unlikely to allow proper natural air infiltration and ventilation.

Air from inside building (boiler in interior room):

•Tightly constructed buildings must be provided with openings to outside for combustion and ventilation air. These openings must be sized to handle all fuel burning appliances, exhaust and ventilation fans and fireplaces.

•When openings to boiler room are taken to interior spaces, provide two permanent openings: a combustion air opening within 12 inches of floor and a ventilation opening within 12 inches of ceiling. Each opening must provide a minimum free area of one square inch per 1,000 Btuh input of all appliances in room plus requirements for any exhaust fans in room. The interior space supplying combustion and ventilation air must have adequate infiltration from outside.

Air directly from outside to boiler room:

•Tightly constructed buildings must be provided with combustion air and ventilation openings to boiler room which are adequate to handle the boiler needs plus the needs of all other

•Combustion and ventilation openings connecting directly or by ducting to outside, or to attic or crawl spaces that freely connect with outside, must be sized as follows:

1.Outside wall or vertical ducting - one square inch per 4,000 Btuh input of all appliances in room plus requirements for any exhaust fans or other appliances in room.

2.Horizontal ducting - one square inch per 2,000 Btuh of all appli- ances in room plus requirements for any exhaust fans or other appliances in room.

3.All ducting must be same size as permanent openings. Minimum size of ducting must be no less than 9 square inches.

4.Other size ducting must comply with local codes.

Part Number

Select the boiler location

•Consider all connections to boiler before selecting a location.

•Boiler must be installed so gas control system components are pro- tected from dripping or spraying water or rain during operation or service.

•

To avoid personal injury, death or property damage, keep boiler area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

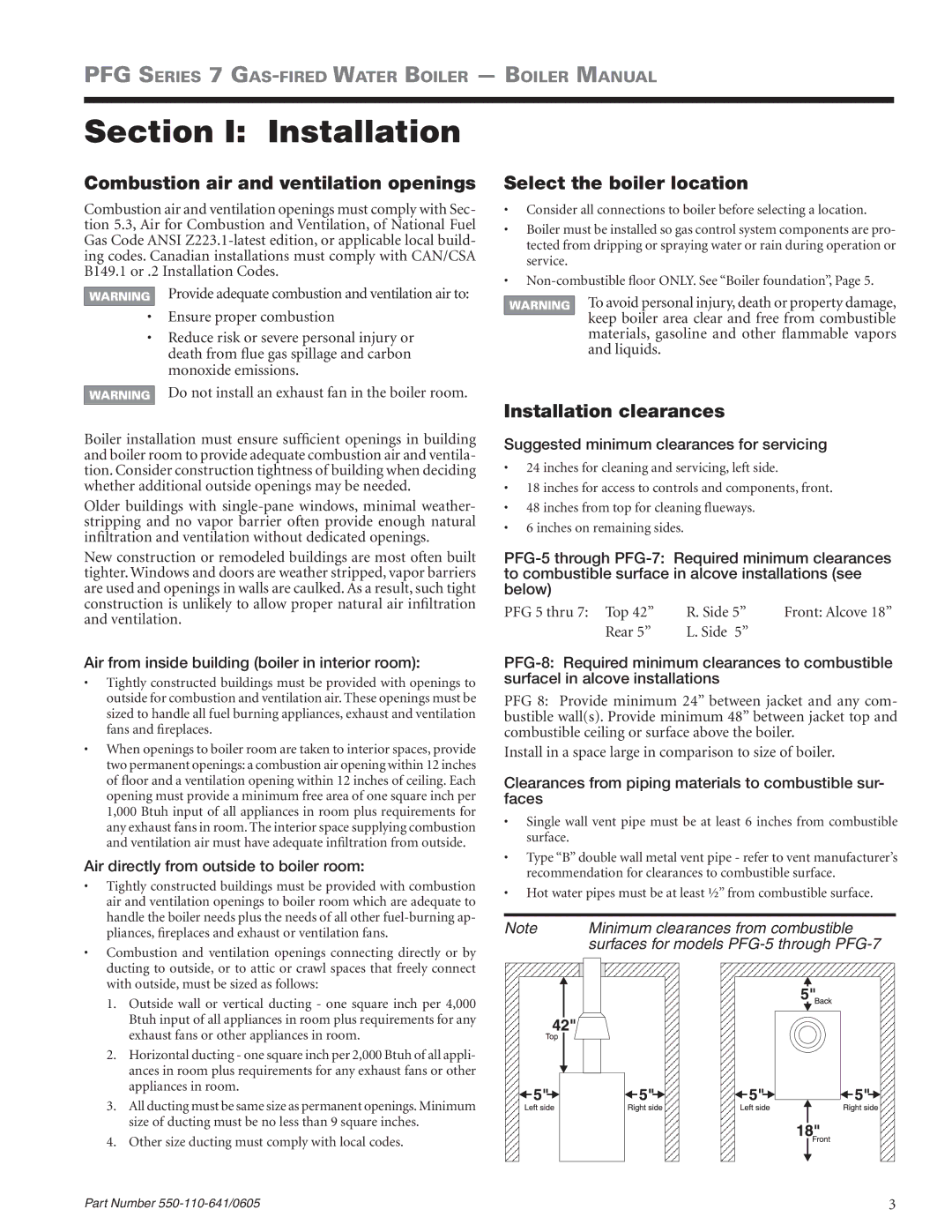

Installation clearances

Suggested minimum clearances for servicing

•24 inches for cleaning and servicing, left side.

•18 inches for access to controls and components, front.

•48 inches from top for cleaning flueways.

•6 inches on remaining sides.

PFG 5 thru 7: Top 42” | R. Side 5” | Front: Alcove 18” |

Rear 5” | L. Side 5” |

|

PFG 8: Provide minimum 24” between jacket and any com- bustible wall(s). Provide minimum 48” between jacket top and combustible ceiling or surface above the boiler.

Install in a space large in comparison to size of boiler.

Clearances from piping materials to combustible sur- faces

•Single wall vent pipe must be at least 6 inches from combustible surface.

•Type “B” double wall metal vent pipe - refer to vent manufacturer’s recommendation for clearances to combustible surface.

•Hot water pipes must be at least ½” from combustible surface.

Note | Minimum clearances from combustible |

| surfaces for models |