PFG Series 7

Boiler piping connections to the heating | 4. Expansion tank installations. | ||||||

system (refer to piping diagrams, Page 7) | a) Closed type expansion tanks - connect from the ¾” N.P.T. | ||||||

| Failure to properly pipe the boiler may result in | expansion tank tapping on the left end section (located just | |||||

| behind the supply outlet tapping) to the expansion tank using | ||||||

| improper operation and damage to the boiler or | ¾” N.P.T. piping. Any horizontal expansion tank piping must | |||||

| building. | pitch upward toward the tank at least 1 inch for each 5 feet of | |||||

These boilers are provided with | piping. | ||||||

b) Diaphragm type expansion tank - may be located anywhere in | |||||||

tems. | |||||||

1. Install relief valve vertically in top ¾” tapping in right end section. | the system, preferably near the boiler. | ||||||

| A manual or automatic type air vent must be | ||||||

| |||||||

See WARNING following. |

| ||||||

| installed in the ¾”N.P.T. tapping when a diaphragm | ||||||

| |||||||

| To avoid water damage or scalding due to relief |

| |||||

|

| type tank is used. | |||||

| valve operation: | The most common cause of lime deposits in boilers is inadequate | |||||

• Discharge line must be connected to relief valve | |||||||

expansion tank volume. If the expansion tank is too small, system | |||||||

| outlet and run to a safe place of disposal. Terminate | water is lost from the relief valve and | |||||

| the discharge line to eliminate possibility of severe | through the fill valve. Eventual section failure will result. | |||||

| burns should the valve discharge. | 5. Connect the system supply piping to the supply outlet tapping on | |||||

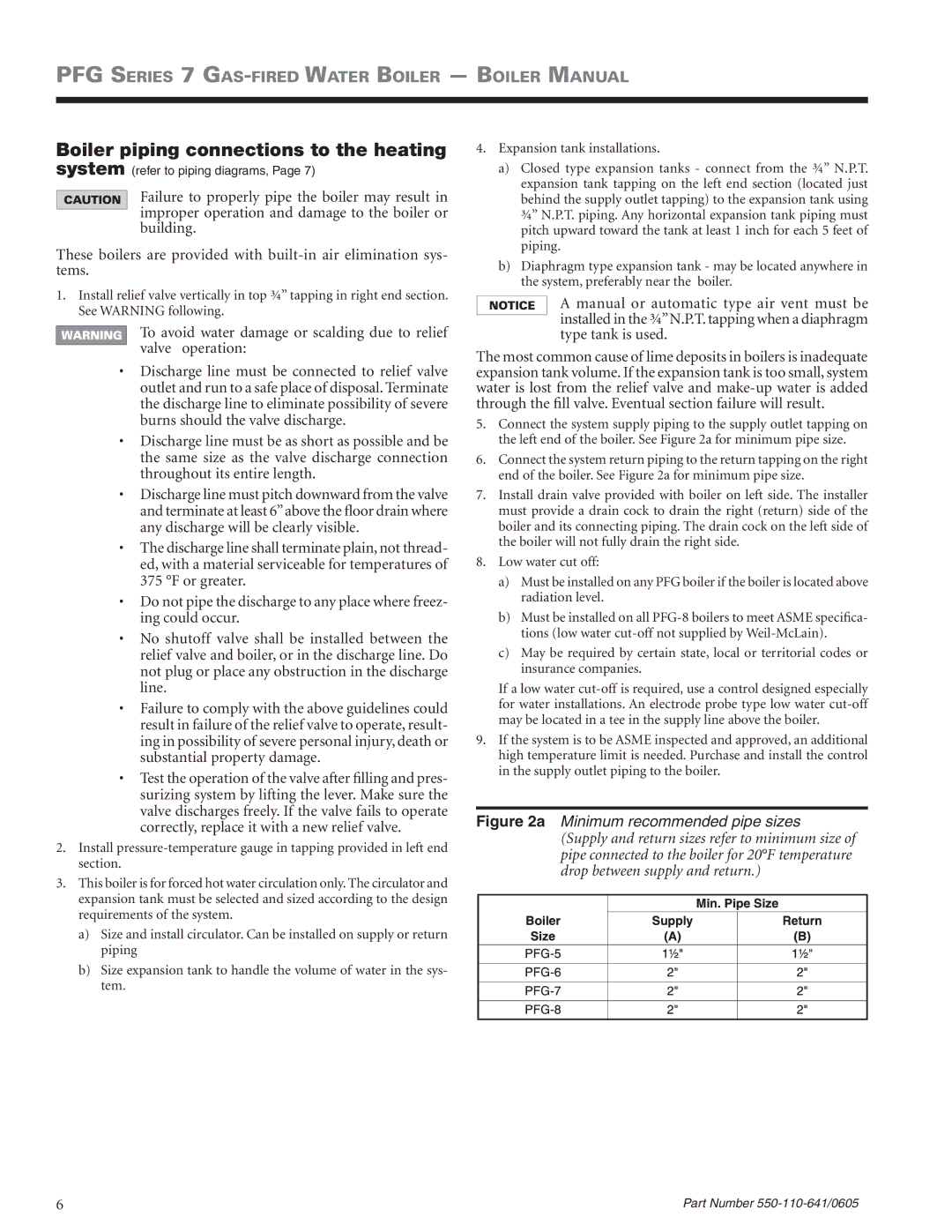

• Discharge line must be as short as possible and be | the left end of the boiler. See Figure 2a for minimum pipe size. | ||||||

| the same size as the valve discharge connection | 6. Connect the system return piping to the return tapping on the right | |||||

| throughout its entire length. | end of the boiler. See Figure 2a for minimum pipe size. | |||||

• Discharge line must pitch downward from the valve | 7. Install drain valve provided with boiler on left side. The installer | ||||||

| and terminate at least 6”above the floor drain where | must provide a drain cock to drain the right (return) side of the | |||||

| any discharge will be clearly visible. | boiler and its connecting piping. The drain cock on the left side of | |||||

• The discharge line shall terminate plain, not thread- | the boiler will not fully drain the right side. | ||||||

8. Low water cut off: | |||||||

| ed, with a material serviceable for temperatures of | ||||||

| 375 °F or greater. | a) Must be installed on any PFG boiler if the boiler is located above | |||||

• Do not pipe the discharge to any place where freez- | radiation level. | ||||||

| ing could occur. | b) Must be installed on all | |||||

• No shutoff valve shall be installed between the | tions (low water | ||||||

c) May be required by certain state, local or territorial codes or | |||||||

| relief valve and boiler, or in the discharge line. Do | ||||||

| not plug or place any obstruction in the discharge | insurance companies. | |||||

| line. | If a low water | |||||

• Failure to comply with the above guidelines could | for water installations. An electrode probe type low water | ||||||

| result in failure of the relief valve to operate, result- | may be located in a tee in the supply line above the boiler. | |||||

| 9. If the system is to be ASME inspected and approved, an additional | ||||||

| ing in possibility of severe personal injury, death or | ||||||

| substantial property damage. | high temperature limit is needed. Purchase and install the control | |||||

• Test the operation of the valve after filling and pres- | in the supply outlet piping to the boiler. | ||||||

|

|

|

|

| |||

| surizing system by lifting the lever. Make sure the |

|

|

|

|

| |

| valve discharges freely. If the valve fails to operate |

|

|

|

|

| |

Figure 2a Minimum recommended pipe sizes | |||||||

| correctly, replace it with a new relief valve. | ||||||

|

| (Supply and return sizes refer to minimum size of | |||||

2. Install |

| ||||||

| pipe connected to the boiler for 20°F temperature | ||||||

section. |

| ||||||

| drop between supply and return.) | ||||||

3. This boiler is for forced hot water circulation only. The circulator and |

| ||||||

|

|

|

|

| |||

expansion tank must be selected and sized according to the design |

|

|

|

|

| ||

|

|

|

|

| |||

requirements of the system. |

|

|

|

|

| ||

|

|

|

|

| |||

a) Size and install circulator. Can be installed on supply or return |

|

|

|

|

| ||

piping |

|

|

|

|

| ||

|

|

|

|

| |||

b) Size expansion tank to handle the volume of water in the sys- |

|

|

|

|

| ||

|

|

|

|

| |||

tem. |

|

|

|

|

| ||

|

|

|

|

| |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Part Number