General Information

Unpack

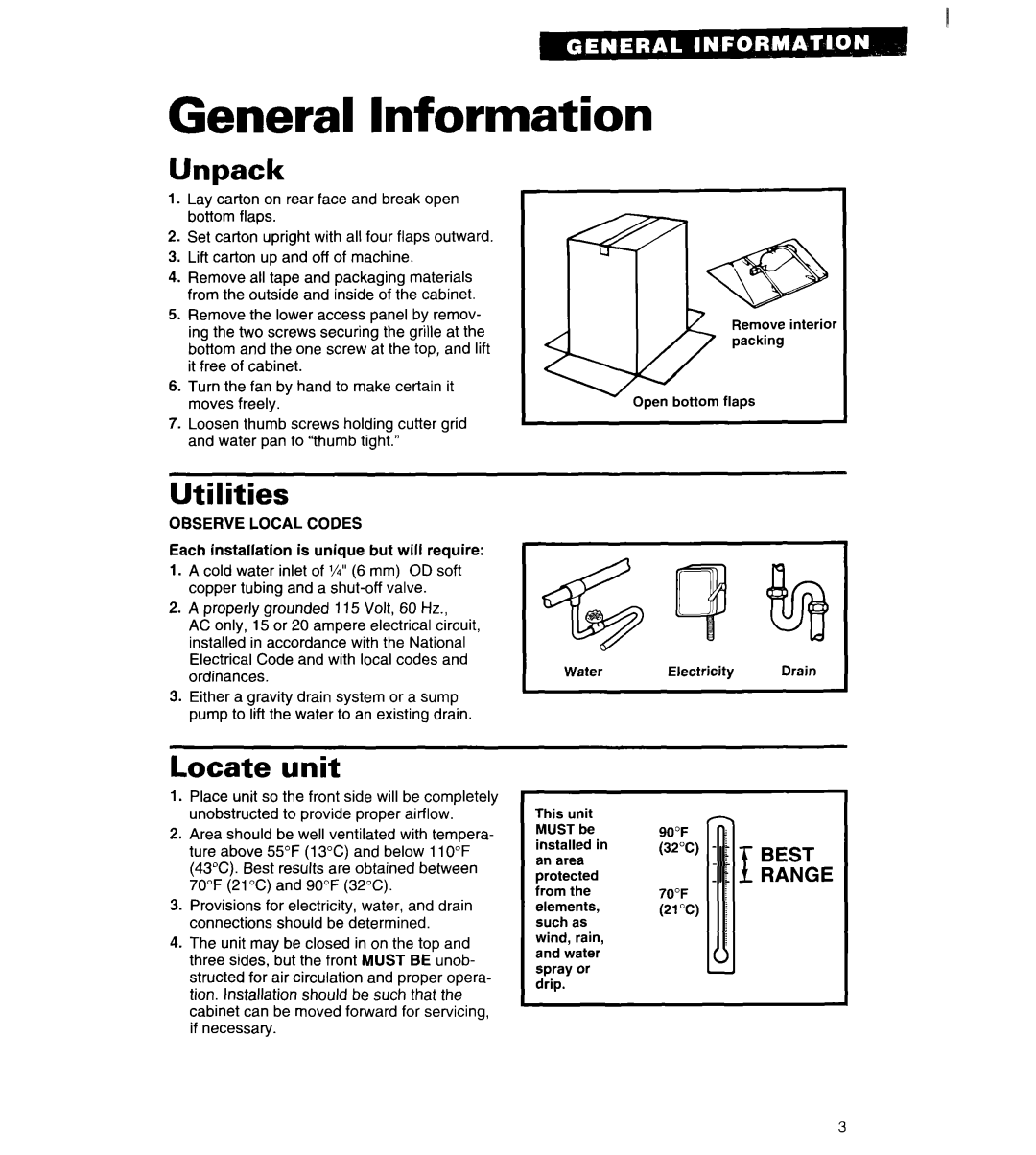

1.Lay carton on rear face and break open bottom flaps.

2.Set carton upright with all four flaps outward.

3.Lift carton up and off of machine.

4.Remove all tape and packaging materials from the outside and inside of the cabinet.

5.Remove the lower access panel by remov- ing the two screws securing the grille at the bottom and the one screw at the top, and lift it free of cabinet.

6.Turn the fan by hand to make certain it moves freely.

7.Loosen thumb screws holding cutter grid and water pan to “thumbtight.”

Utilities

OBSERVE LOCAL CODES

Each installation is unique but will require:

1.A cold water inlet of W (6 mm) OD soft copper tubing and a

2.A properly grounded 115 Volt, 60 Hz.,

AC only, 15 or 20 ampere electrical circuit, installed in accordance with the National Electrical Code and with local codes and ordinances.

3.Either a gravity drain system or a sump pump to lift the water to an existing drain.

Locate | unit |

|

|

|

| ||

1. Place unit so the front side will be completely |

|

| |||||

| unobstructed | to provide | proper | airflow. | This | unit | |

2. | Area should | be well ventilated | with tempera- | MUST be | |||

| ture above 55°F (13°C) and below 110°F | installed in | |||||

| an area | ||||||

| (43°C). Best results are obtained between | ||||||

| protected | ||||||

| 70°F (21 “C)and 90°F (32%). |

| |||||

|

| from | the | ||||

3. | Provisions for electricity, | water, | and drain | ||||

elements, | |||||||

| connections | should be determined. | such | as | |||

4. The unit may be closed | in on the top and | wind, | rain, | ||||

| three sides, but the front MUST BE unob- | and water | |||||

| spray | or | |||||

| structed for air circulation and proper opera- | ||||||

| drip. |

| |||||

| tion. Installation should be such that the |

| |||||

|

|

| |||||

cabinet can be moved forward for servicing, if necessary.

Remove interior

Electricity

BEST

RANGE

3