contact | a | quaIlfled | electrIcIan | to | |

OSSUE that | the electrical | lnstollat~on | |||

15adequate | and | IS in | conformance | ||

v/lth | National | ElectrIcal | Code |

| |

ANSl/NFPA | 70.latest | edItron. | and | ||

local | codes | and | ordinances |

| |

Allow slack I” the line between the

wall and the appliance so that it

con be moved if servicing is ever

necessarv A 3/4”. U L

relref must be provided at each end of the power supply cable (at the

appliance and at the IunctIon box)

|

|

|

|

| Frgure |

| 3 |

|

|

|

|

| |

5. If you | must | change |

| to | a |

|

|

| |||||

|

| single | phase, | 120/240- |

| ||||||||

volt, |

| AC | only, |

| electrical |

|

|

| |||||

supply | system, | and | local | codes |

|

| |||||||

permit, | a |

| 120/240- |

|

|

| |||||||

voll | minimum, |

| dryer |

|

| ||||||||

power | supply |

| cord | kil wilh a |

|

|

| ||||||

receplocle |

|

| of | NEMA |

| Type |

| ||||||

may |

| be | used. | (See Figure 3.) This |

| ||||||||

cord |

| must | contain |

| three. |

|

| ||||||

copper |

| conductors |

| with | ring |

|

|

| |||||

terminals |

| or | spade |

| terminals | with |

| ||||||

upturned |

| ends | on |

| the | washer/dryer |

| ||||||

end. | Where | local | codes | permit. | it |

| |||||||

must | be | plugged | Into | a | mating | 30. |

| ||||||

amp | receptacle |

| (NEMA | type |

|

|

| ||||||

| Cord | should | be | Type |

| SRD | or | ||||||

SRDT and be at leost four feet long |

| ||||||||||||

The |

| power | supply | cord | IS | ||||||||

not | provided |

| with |

| the | washer/dryer. |

| ||||||

A kit, | Part | No. | 687104. | IS available |

|

| |||||||

from | your | WhIrlpool |

| dealer. |

|

|

| ||||||

NOTE: | If | local | codes |

| requrre |

|

|

| |||||

permanently |

|

| connected | wiring, | see | ||||||||

“Alternate |

|

| electrlcol |

|

| connection”. |

|

| |||||

Panels | F and | G. |

|

|

|

|

|

|

| ||||

To | convert |

|

| to | electrlcal |

| |||||||

system, | the |

| power | supply |

| ||||||||

cord | must |

| be | removed |

| and | the |

| |||||

appliance |

|

| cabinet |

| must | be |

|

|

| ||||

grounded |

|

| according |

| to | local |

| codes | |||||

either | by | “sing the | neutral | terminal |

| ||||||||

or | a | separate |

| grounding | wire. | (See |

| ||||||

Panel | F, |

| “Alternate |

| electrical |

|

|

| |||||

connectton”, |

|

| for | detolled |

|

|

|

| |||||

irstructions |

|

| 1 |

|

|

|

|

|

|

|

| ||

Exhaust requirements

Fire Hazard

. Do Nol use

. Do Not use metal duct smaller than four inches I” diameter.

-Do Not use exhaust hoods with

mognetrc latches.

Improper crir supply for exhausting moy result In a fire.

- Check | Ihat | exhaust | system | is | ||||

not | longer |

| lhon | spectfied. |

|

| ||

Exhaust |

| systems | longer | than |

| |||

specrlied | will: |

|

|

|

| |||

Accumulate |

| lint. |

|

|

| |||

Shorten |

| the | life | of the | product. |

| ||

Reduce |

| performance. |

| Result | in | |||

longer | drying | times | and |

|

| |||

increase | energy | usage. |

|

| ||||

Failure |

| to | follow | specificolrons |

| |||

may | result | In | 0 fire. |

|

|

| ||

. Do Not exhaust dryer into 0

chimney, furnace cold oil duct. attic or crawl space, or ony other duct used for venting.

. Clean the exhaust system every other yeor.

-Do Not Install flexible duel under wall, celling or floor materlols

Accumulaled | lent could | result in o |

fire or cause | moisture | domage. |

Use | duel | lape | to |

|

seal | all joints. |

|

| |

rigid, |

|

| ||

metal | pipe | is |

|

|

preferred | Plan |

| ||

lnstallatron | to | use lhe fewest | number | |

of elbows | and | turns. |

| |

Exhaust aMlow | Exhaurl Oi”,OW |

Metal. flexible duct must be fully

extended and supported when the dryer is in its frnal position. DO NOT KINK OR CRUSH THE DUCT. The metal flexible duct must be

completely open to allow adequate exhaust air to flow

Allow |

| as | much | room | as | possible |

| |

when |

| usmg | elbows | or making | turns. | |||

Bend |

| duct | gradually | to | avoid |

| ||

kinking. |

| Remove |

|

|

|

| ||

excess, |

| flexible | duct |

|

|

| ||

to avoid | sagging |

|

|

|

| |||

and | klnklno | thai |

|

| ||||

may | resultln |

|

|

|

| |||

reduced |

|

| alrflow. |

|

|

|

| |

The | exhaust | duct |

|

|

| |||

Space requirements are provided on the back cover of Installation

Instructions and on the rear panel of the washer/dryer.

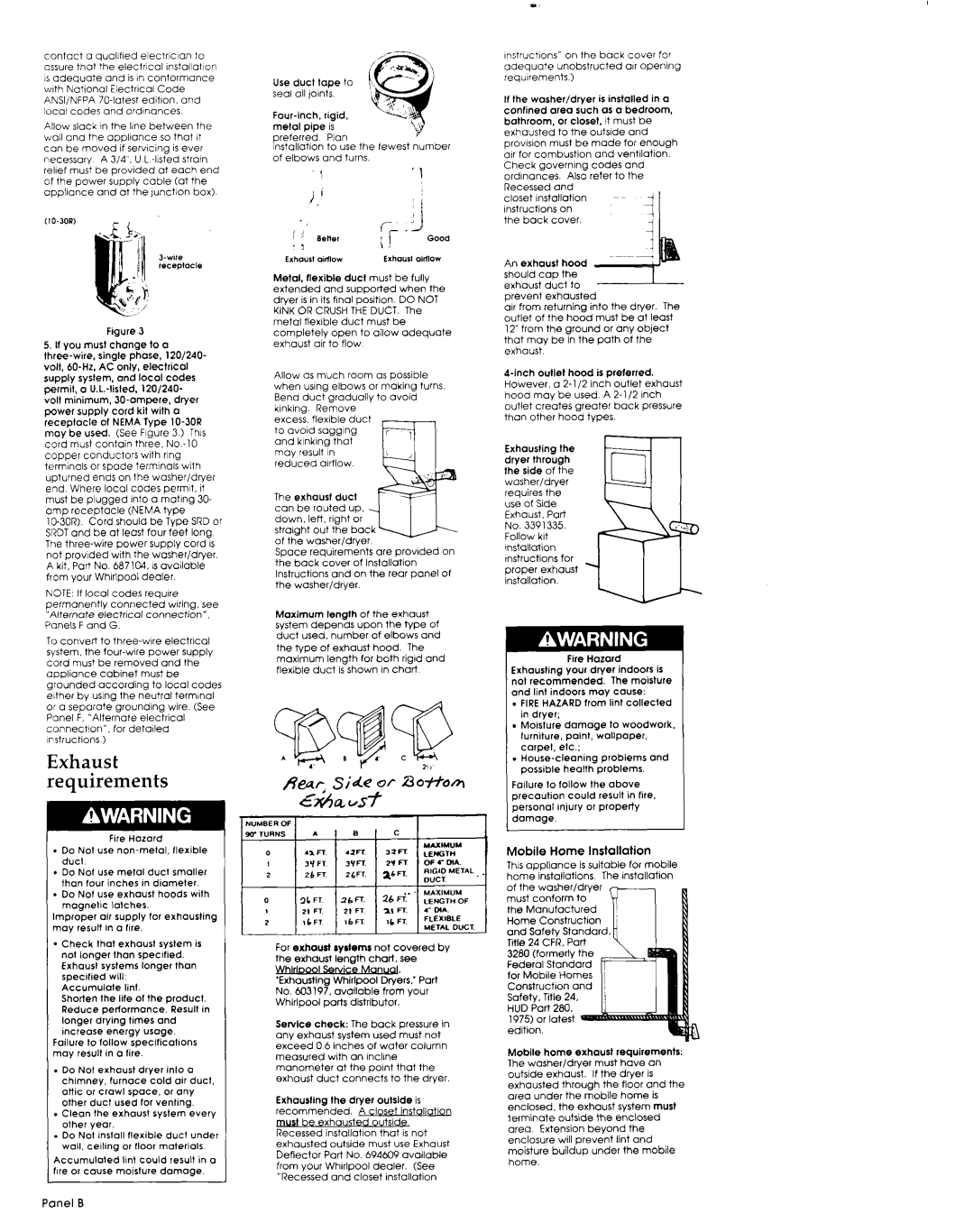

Maximum |

| length | of | the | exhaust |

| ||

system | depends | upon | the type | of | ||||

duct | used. | number |

| of | elbows | and | ||

the | type | of | exhaust |

| hood. | The |

| |

maximum |

| length | for | both | rigrd | and | ||

flexible | duct | is shown |

| I” | chart |

| ||

For | exhausl | ryslems | not covered | by | ||

the | exhaust | length | see |

| ||

&hlrlo00l | Service |

|

|

|

| |

‘Exhausting | Whirlpool | Dry&s.’ | Part | |||

No. | 603197, | available | from | your | ||

Whirlpool | parts | distributor. |

|

| ||

Service check: The back pressure in any exhaust system used must not

exceed 0 6 inches of water column

measured with an rncllne

manometer at the point that the

exhaust duct connects to the dryer.

Exhausting the dryer outside is

recommended. A closet instollotlon

m!&l be exhausted outside.

Recessed installatron that is not

exhausted outside must use Exhaust

Deflector Part No. 694609 available

from your Whrrlpool dealer. (See “Recessed and closet installation

InstructIons” |

| on | the | back | co”or | for | ||||||

adequate |

| unobstructed |

|

| afr | opening | ||||||

req”lrements.1 |

|

|

|

|

|

|

|

|

| |||

II the | washer/dryer |

| is | installed | in | a | ||||||

confined | area |

| such as | a | bedroom, |

| ||||||

bathroom, |

| or | closel. | it must | be |

| ||||||

exhausted |

| to | the | outsrde |

| and |

| |||||

provrsron | must |

| be | made |

| for | enough | |||||

air | for | combustion |

| and | ventilation. |

| ||||||

Check | governrng |

| codes |

| and |

| ||||||

ordinances. |

|

| Also | refer |

| to | the |

| ||||

Recessed | and |

|

|

|

|

|

|

|

| |||

closet | rnstollation |

|

|

|

|

|

|

| ||||

Instructions |

| on |

|

|

|

|

|

|

| |||

the | back | cover. |

|

|

|

|

|

|

| |||

An | exhaust | hood |

|

|

|

|

|

| ||||

should | cap | the |

|

|

|

|

|

|

| |||

exhaust |

| duct | to |

|

|

|

|

|

| |||

prevent |

| exhausted |

|

|

|

|

|

| ||||

air | from | returning |

| into | the | dryer. | The | |||||

outlet | of | the | hood | must |

| be | ut least | |||||

12’ | from | the | ground | or | any | object |

| |||||

that | may | be | in | the | path |

| of | the |

| |||

exhaust. |

|

|

|

|

|

|

|

|

|

|

| |

outlet |

| hood | is | preferred. |

| |||||||

However, | a | inch |

| outlet | exhaust | |||||||

hood | may | be |

| used | A |

| ||||||

outlet | creates |

| greater |

| back | pressure | ||||||

than | other | hood | types. |

|

|

|

| |||||

Exhausting |

| the |

|

|

|

|

|

|

| |||

dryer | through |

|

|

|

|

|

|

|

|

| ||

the | side | of | the |

|

|

|

|

|

|

| ||

washer/dryer |

|

|

|

|

|

|

|

|

| |||

requires |

| the |

|

|

|

|

|

|

|

|

| |

use | of | Side |

|

|

|

|

|

|

|

|

| |

Exhaust. | Part |

|

|

|

|

|

|

|

| |||

No. | 3391335. |

|

|

|

|

|

|

|

|

| ||

Follow | kit |

|

|

|

|

|

|

|

|

| ||

installation |

|

|

|

|

|

|

|

|

|

| ||

Instructions |

| for |

|

|

|

|

|

|

| |||

proper | exhaust |

|

|

|

|

|

|

|

| |||

installation.

|

|

|

| Fire |

| Hozard |

|

| |

Exhausting | your |

| dryer | indoors | iS | ||||

nol |

| recommended. |

|

| The | moisture | |||

and | lint | indoors |

| moy | cause: |

| |||

. | FIRE | HAZARD | from | lint | collected | ||||

| in | dryer; |

|

|

|

|

|

| |

. | Morsture | damage | to woodwork, | ||||||

| lurniture, | point, |

| wallpaper, |

| ||||

| carpet. |

| etc.; |

|

|

|

|

| |

. |

| problems | and | ||||||

| possible | health |

| problems. |

| ||||

Follure | lo | follow |

| the | above |

| |||

precaution | could | result | in fire. | ||||||

personal |

| rnjury |

| or property |

|

| |||

domoge. |

|

|

|

|

|

|

| ||

Mobile Home Installation

This | appliance |

| is suitable | for | mobile | |||

home | installations. | The | installation | |||||

of the | washer/dryer |

|

|

| ||||

must |

| conform |

| to |

|

|

| |

the | Manufactured |

|

|

| ||||

Home | Construction |

|

|

| ||||

and | Safety | Standard. |

|

|

| |||

Title | 24 CFR, |

| Part |

|

|

| ||

3280 | (formerly | the |

| \ | 81 | |||

Federal |

| Standard |

|

|

| |||

for | Mobrle |

| Homes |

|

|

| ||

Construction |

| and | 1i |

| I | |||

Safety. | Title | 24, | I |

|

| |||

HUD |

| Part | 280. |

| Ii |

|

| |

1975) | or | latest | d |

|

|

| ||

edition. |

|

|

|

|

|

|

| |

Mobile home exhaust requirements:

The washer/dryer must have an

outside exhaust. If the dryer is

exhausted through the floor and the area under the mobile home is

enclosed, the exhaust system must

terminate outside the enclosed

area Extension beyond the

enclosure will prevent lint and moisture buildup under the mobile home.

Panel B