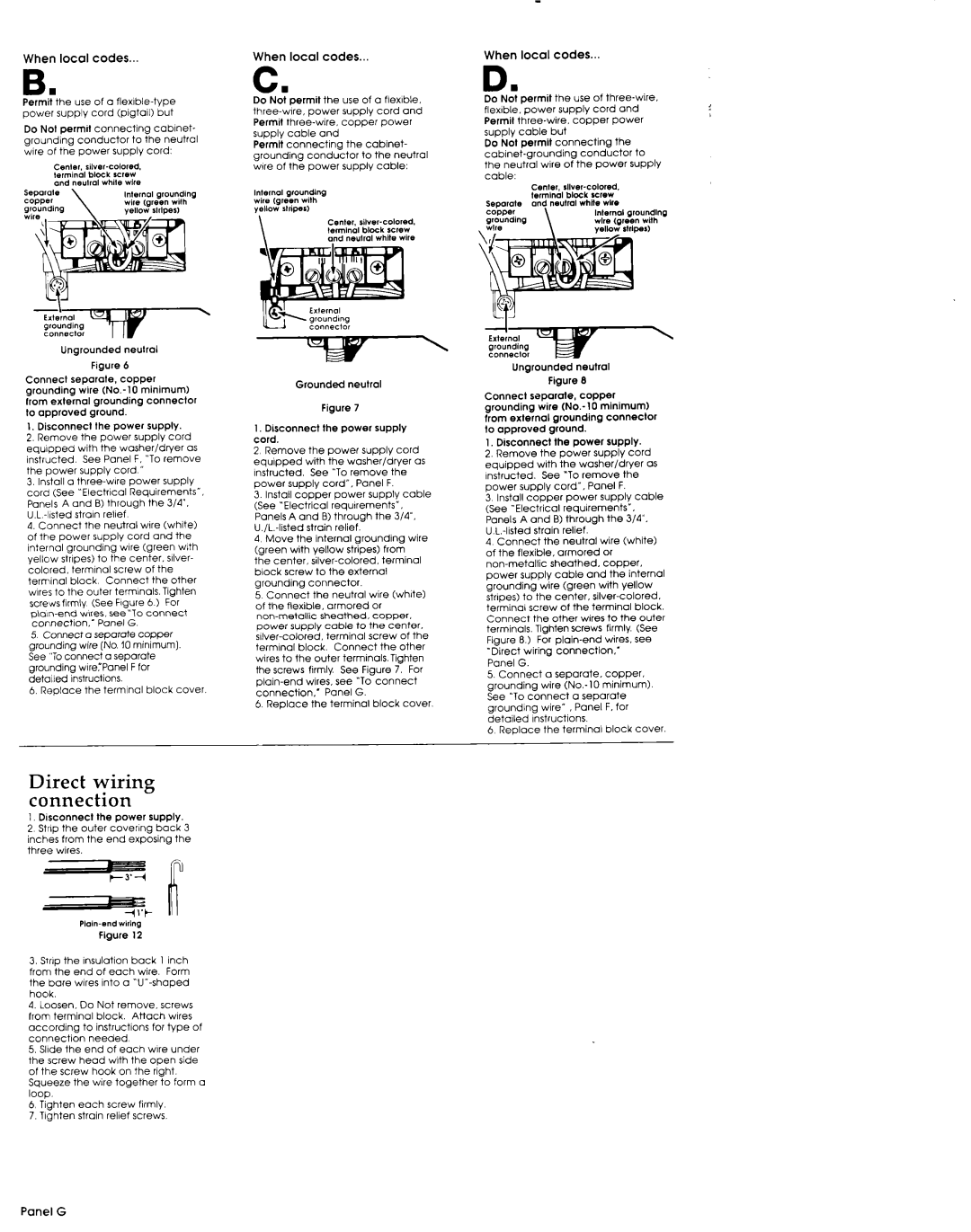

When local codes..

B.

Permit the use of a

power supply cord (pigtail) but

Do Nol permrt connecting cabrnet-

grounding conductor to the neutral wire of the power supply cord:

| Ungrounded |

| neutral |

| |||

|

|

| Figure | 6 |

|

| |

Connect | seporole. | copper |

| ||||

grounding |

| wire | minimum) | ||||

from external | grounding | connector | |||||

to | approved |

| ground. |

|

|

| |

I, | Disconnect | Ihe | power | supply. | |||

2. | Remove |

| the | power | supply | cord | |

equipped |

| with | the | washer/dryer | as | ||

instructed. |

| See | Panel | F, “To remove | |||

the | power |

| supply |

| cord | ” |

|

3.Install a

4.Connect the neutral wire (white) of the power supply cord and the

internal grounding wire (green with yellow stripes) to the center. sliver-

colored, terminal screw of the

terminal block Connect the other wires to the outer terminals.Tighten screws firmly (See Figure 6 1 For

connection: |

| Panel | G. |

| ||

5 | Connect | a separate | copper |

| ||

grounding | wire | (No. | IO | minimum) |

| |

See | “Toconnect | a separate |

| |||

grounding | wIrerPanel |

| F for |

| ||

detolled | Instructions. |

|

|

| ||

6. Replace | the | terminal | block | cover. | ||

Direct | wiring |

|

| ||||

connection |

|

|

| ||||

1. | Disconnect | the | power | supply. |

| ||

2 | Strip | the | outer | covering | back | 3 | |

inches | from | the | end | exposing | the | ||

three | wires. |

|

|

|

|

| |

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

| LIZ |

|

|

| i |

| |

|

|

|

|

| |||

|

|

| Figure | 12 |

|

| |

3.Srrlp the Insulation back 1 inch from the end of each wire. Form the bare wires into a

4.Loosen. Do Not remove. screws

from terminal block. Attach wires

according to instructions for type of

connection needed

5.Slide the end of each wire under the screw head with the open side of the screw hook on the right.

Squeeze the wire together to form a loop.

6Tighten each screw firmly.

7.Tlghten strain relief screws.

When local codes...

c.

Do Not permit the use of a flexible.

Permit

Permit connecting the cabinet-

grounding conductor to the neutral w!re of the power supply cable:

tnternat grounding wire (green with yellow rlrip%r)

center.

\and neutral white wile

|

|

|

| Grounded | neutral |

|

|

| |||||

|

|

|

|

|

| Figure | 7 |

|

|

|

| ||

I. | Disconnect |

| the | power | supply |

| |||||||

cord. |

|

|

|

|

|

|

|

|

|

|

|

| |

2 | Remove |

| the | power |

| supply |

| cord | |||||

equipped |

|

| with | the | washer/dryer |

| as | ||||||

Instructed. |

| See | “To remove |

| the |

| |||||||

power | supply | Panel | F. |

| |||||||||

3. | Install |

| copper | power |

| supply | cable | ||||||

(See | “Electrical | requirements”. |

|

|

| ||||||||

Panels | A | and | 8) through | the | 3/4’. |

| |||||||

| strain | relief. |

|

|

|

|

| ||||||

4 | Move |

| the | internal |

| grounding |

| wire | |||||

tareen | with |

| vellow | stripes) | from |

| |||||||

i6e |

| center, |

|

| terminal |

| |||||||

block |

| screw |

| to | the | external |

|

|

| ||||

grounding |

| connector. |

|

|

|

|

| ||||||

5 | Connect |

|

| the | neutral |

| wire |

| (white) | ||||

of | the | flexible, | armored |

| or |

|

|

| |||||

|

| sheathed, |

| cooper. |

| ||||||||

power | supply |

| cable |

| to | the | center. |

| |||||

|

| terminal |

| screw | of | the | |||||||

terminal |

| block. | Connect | the | other | ||||||||

wires | to | the | outer | terminalsTighten |

| ||||||||

the | screws | firmly | See |

| Figure |

| 7. | For | |||||

| wires, | see | “To connect |

| |||||||||

connection.’ |

|

|

| Panel | G. |

|

|

| |||||

6. | Replace |

|

| the | terminal | block | cover. | ||||||

When local codes...

D n

Do | Not | oermit |

| the | use | of | ||||

flex!bie.‘power |

|

| supply | cord |

| and | ||||

Permit |

| copper |

| Power | ||||||

supply | cable | but |

|

|

|

|

| |||

Do | Not | permit |

| connecting |

|

| the | |||

|

| conductor |

| to | ||||||

the | neutral | wire | of | the | power | supply | ||||

cable: |

|

|

|

|

|

|

|

|

| |

|

|

| Cente,. |

|

|

| ||||

|

|

| terminal | block | screw |

|

| |||

Sepmate |

| and | neutral | while | wtre |

| ||||

copper |

|

|

|

|

| Internal | groundtng | |||

grounding |

|

|

|

|

| wtre | (green with | |||

\ wtre |

|

|

| \ |

|

| yellow |

| stripes) | |

Ungrounded neutral

Figure 8

Connect saparale, copper

grounding wire

from external grounding connector

to | approved | ground. |

|

|

1, | Disconnect | the power | supply. | |

2. | Remove | the power | supply | cord |

equipped |

| with | the | washer/dryer | as | |||||

Instructed. |

| See | “To remove | the | ||||||

power |

| supply | cord”, | Panel | F. |

| ||||

3 | Install | copper |

| power | supply | cable | ||||

(See | “Electrical |

| requirements”. |

|

| |||||

Panels |

| A | and | B) | through | the |

| 3/4’. | ||

| strain |

| relief. |

|

|

| ||||

4 | Connect | the |

| neutral | wire | (white) | ||||

of | the | flexible, | armored | or |

|

| ||||

sheathed. | copper. | |||||||||

power |

| supply | cable | and | the | internal | ||||

grounding |

| wire |

| (green | with | yellow | ||||

strrpes) | to | the | center, | |||||||

terminal | screw | of the terminal |

| block. | ||||||

Connect |

| the other | wires | to | the outer | |||||

terminals, |

| Tighten | screws | firmly. | (See | |||||

Fiaure |

| 8.1 | For | wires. | see | |||||

| V~ |

|

|

|

|

|

|

|

|

|

“Direct | wiring | cOnneC~lOn.~ |

|

| ||||||

Panel | G. |

|

|

|

|

|

|

| ||

5. | Connect | a | separate. | copper. | ||||||

grounding |

| wire | minimum). | |||||||

See | ‘~To connect |

| a | separate |

|

| ||||

grounding |

| wire’ | , Panel | F. for |

| |||||

detailed |

| Instructions. |

|

|

|

| ||||

6 | Replace | the |

| terminal | block | cover. | ||||