Now start...

With range in kitchen.

1 w Remove racks and other parts from inside oven.

2 W Place one foot on the shipping base. Tilt range forward slightly to free rear legs. Gently lower range to floor. Tilt range backwards until legs are free.

3 w Remove shipping

materials, tape and protective film from range. Do Not remove cardboard shipping base at this time.

4 W Lower leveling legs approximately l/4 inch or to a point where the range base does not touch the floor.

the line drawn.

Note: If there is a cabinet on only one side, the anti-tip bracket must be installed against the cabinet,

Go to Step 7.

6 A If range is Not installed against a n

cabinet, both anti-tip brackets must be installed.

l Slide range into final location. Mark a line on the floor along sides of range about one-half the distance from the rear

to the front.

-;iI

lineA-

l Mark floor to show where the center of the rear leveling legs are on the right and left sides of range. Slide range out of location. Draw a straight line between the two marks.

&n Check

that the rear leveling leg is engaged in the anti-tip bracket. (For no-cabinet installations, check that both rear legs are engaged in anti- tip brackets.) If a leveling leg is not properly engaged,

remove and reposition the bracket to insure that the leveling leg fits properly in the bracket.

13 w Place rack in oven. Place level on rack, first side to side; then front to back. If the range is not level, pull the range forward until rear leveling leg is removed from the bracket. Adjust the legs up or down until range is level. Push range back into position. Check that the rear leveling leg is engaged in the bracket.

Note: Oven must be level for satisfactory baking conditions.

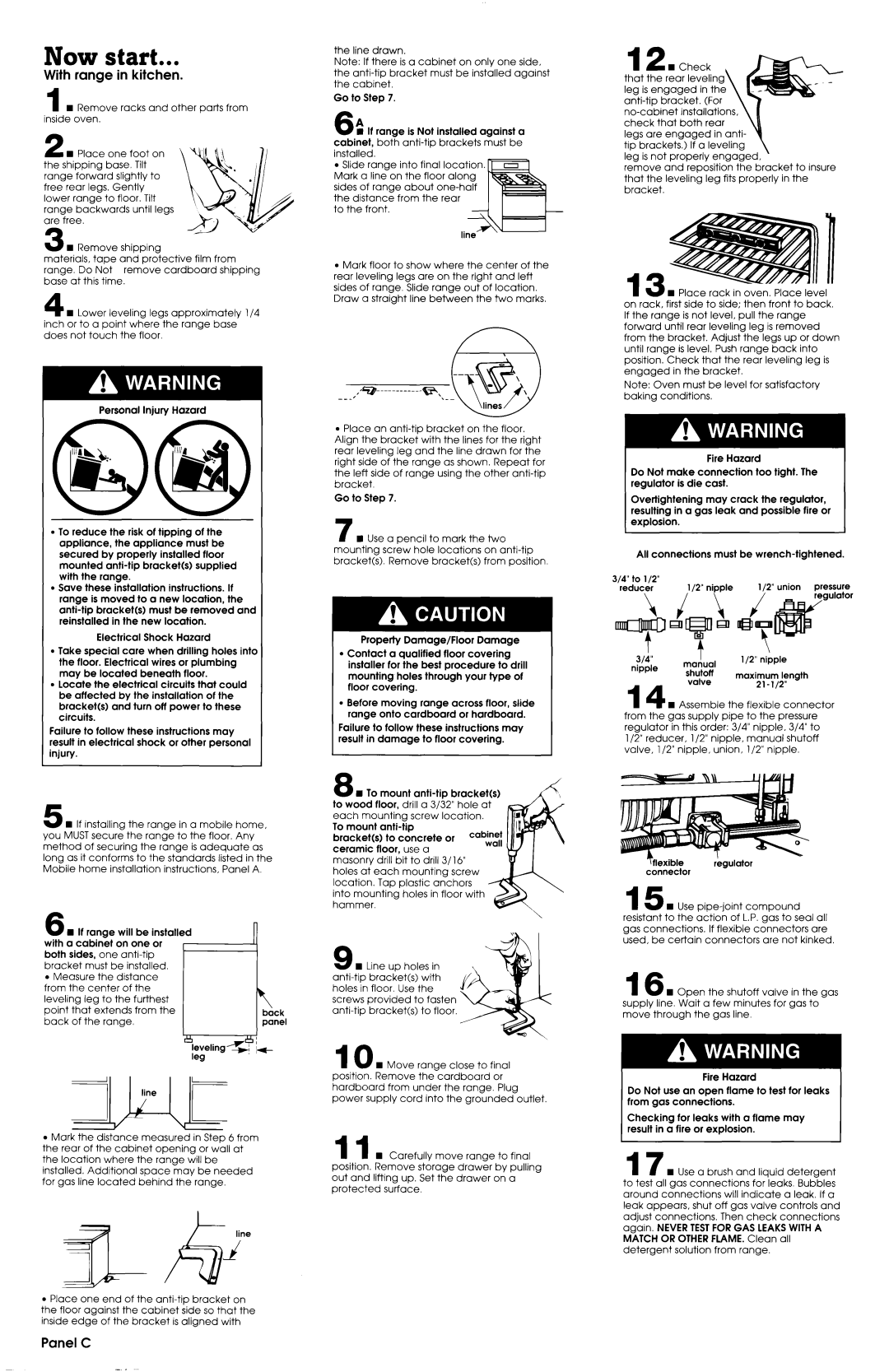

Personal Injury Hazard

lTo reduce the risk of tipping of the appliance, the appliance must be secured by properly installed floor mounted anti-tip bracket(s) supplied

with the range.

l Save these installation instructions. If range is moved to a new location, the anti-tip bracket(s) must be removed and reinstalled in the new location.

Electrical Shock Hazard

l Take special care when drilling holes into the floor. Electrical wires or plumbing may be located beneath floor.

l Locate the electrical circuits that could be affected by the installation of the bracket(s) and turn off power to these circuits.

Failure to follow these instructions may result in electrical shock or other personal injury.

3n If installing the range in a mobile home, you MUST secure the range to the floor. Any method of securing the range is adequate as long as it conforms to the standards listed in the Mobile home installation instructions, Panel A.

6 n If ranae will be installed with a cabinet on one or both sides, one anti-tip bracket must be installed,

l Measure the distance from the center of the leveling leg to the furthest point that extends from the back of the range.

I1 61

leveling*+j k leg

l Mark the distance measured in Step 6 from the rear of the cabinet opening or wall at the location where the range will be installed. Additional space may be needed for gas line located behind the range,

l Place one end of the anti-tip bracket on the floor against the cabinet side so that the inside edge of the bracket is aligned with

l Place an anti-tip bracket on the floor. Align the bracket with the lines for the right rear leveling leg and the line drawn for the right side of the range as shown. Repeat for the left side of range using the other anti-tip bracket.

Go to Step 7.

7

1n Use a pencil to mark the two mounting screw hole locations on anti-tip bracket(s). Remove bracket(s) from position

Property Damage/Floor Damage

l Contact a qualified floor covering installer for the best procedure to drill mounting holes through your type of floor covering.

l Before moving range across floor, slide range onto cardboard or hardboard.

Failure to follow these instructions may result in damage to floor covering.

L

8n To mount anti-tip bracket(s) to wood floor, drill a 3/32” hole at each mounting screw location.

To mount anti-tip

bracket(s) to concrete or cabts! ceramic floor, use a

masonry drill bit to drill 3/ 16” holes at each mounting screw location. Tap plastic anchors into mounting holes in floor with hammer.

9W Line up holes in

anti-tip bracket(s) with holes in floor. Use the screws provided to fasten anti-tip bracket(s) to floor

10 w Move ranae close to final

position. Remove thevcardboard or hardboard from under the range. Plug power supply cord into the grounded outlet.

11 n Carefully move range to final position. Remove storage draw& by pulling out and lifting up. Set the drawer on a protected surface.

Fire Hazard

Do Not make connection too tight. The regulator is die cast.

Overtightening may crack the regulator, resulting in a gas leak and possible fire or explosion.

All connections must be wrench-tightened.

JW’d’,“t’e2”

l/2” nipple l/2” union pressure

| w | | 1 | J | |

T-T- | 3/A” | | | “p | nipple |

| manual | | l/2” |

| nipple | | | |

| shutoff | maximum length |

| |

| | valve | | 21-l/2” |

14 w Assemble the flexible connector |

from the gas supply pipe to the pressure |

regulator in this order: 3/4” nipple, 3/4” to |

l/2” reducer, l/2” nipple, manual shutoff |

valve, l/2” nipple, | union, | l/2” | nipple. |

Tflexible regulator connector

15 w Use pipe-joint compound

resistant to the &&ion of L.P. g&s to seal all gas connections. If flexible connectors are used, be certain connectors are not kinked.

16 W Open the shutoff valve in the aas supply line. tiait a few minutes for gas to - move through the gas line.

Fire Hazard

Do Not use an open flame to test for leaks from gas connections.

Checking for leaks with a flame may result in a fire or explosion.

17 w Use a brush and liquid detergent to test all gas connections for leaks. Bubbles around connections will indicate a leak. If a leak appears, shut off gas valve controls and adjust connections. Then check connections again. NEVERTESTFORGAS LEAKSWITH A MATCH OR OTHERFLAME. Clean all detergent solution from range.