Option 1 (Recommended Method)

Flexible stainless steel gas connector:

■■ If local codes permit, use a new flexible stainless steel gas connector (Design Certified by the American Gas Association or CSA International) to connect your dryer to the rigid gas supply line. Use an elbow and a 3/8" flare x 3/8" NPT adapter fitting between the stainless steel gas connector and the dryer gas pipe, as needed to prevent kinking.

Option 2 (Alternate Method)

Approved aluminum or copper tubing:

■■ Lengths over 20 ft. (6.1 m) can use 3/8" approved tubing (if codes and gas supplier permit).

■■ If you are using Natural Gas, do not use copper tubing.

■■ 3/8" flare x 3/8" NPT adapter fitting between dryer pipe and 3/8" approved tubing.

■■ Lengths over 20 ft. (6.1 m) should use larger tubing and a different size adapter fitting.

■■ If your dryer has been converted to use LP gas, 3/8" LP compatible copper tubing can be used. If the total length of the supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe joint compounds that resist the action of LP gas must be used. Do not use TEFLON®† tape.

Elevations above 10,000 ft. (3,048 m):

■■ When installed above 10,000 ft. (3,048 m) a 4% reduction of the burner B.T.U. rating shown on the model/serial number plate is required for each 1,000 ft. (305 m) increase in elevation.

Gas supply pressure testing

■■ The dryer must be disconnected from the gas supply piping system during pressure testing at pressures greater than 1/2 psi.

Electrical Requirements

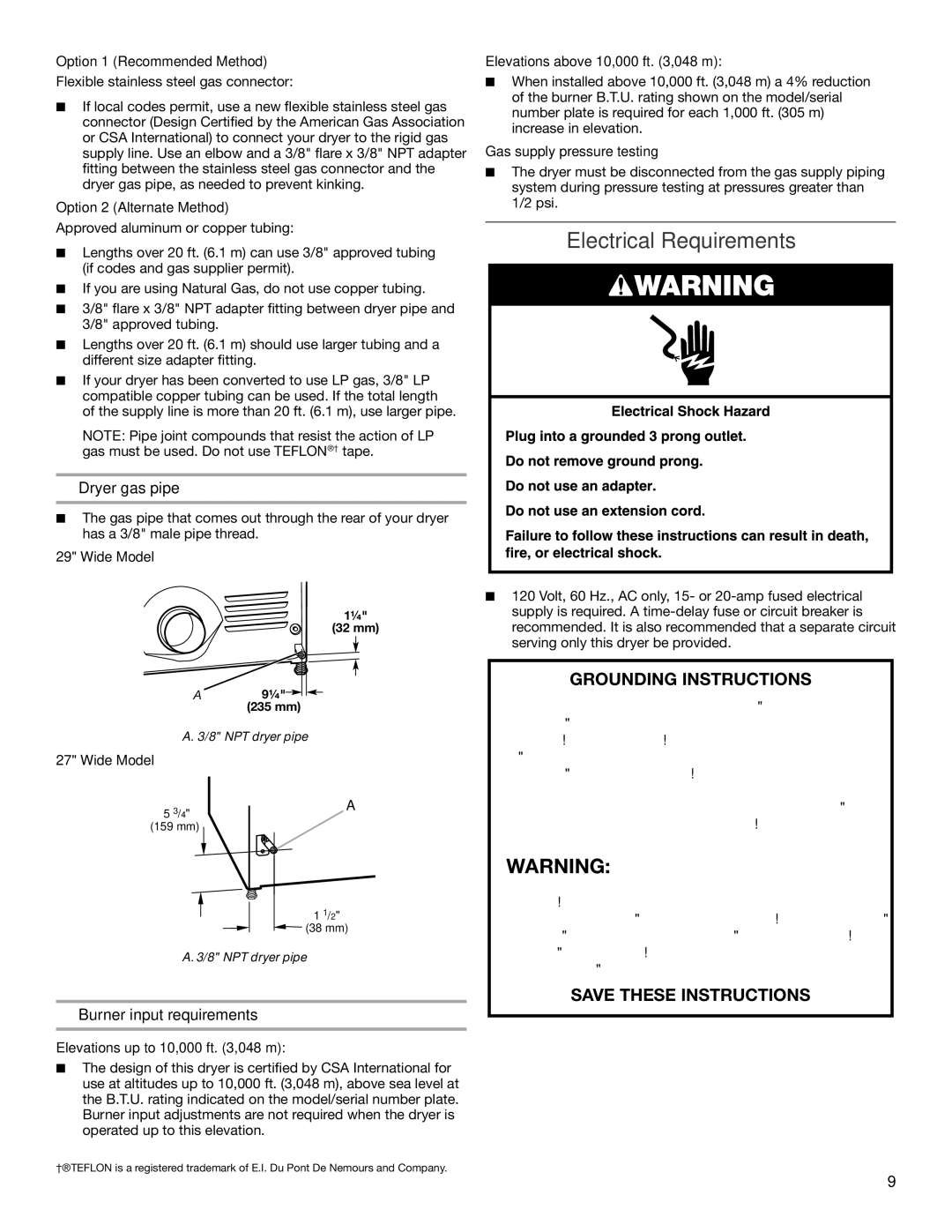

Dryer gas pipe

■■ The gas pipe that comes out through the rear of your dryer has a 3/8" male pipe thread.

29" Wide Model

1¼"

(32 mm)

A9¼"![]()

![]() (235 mm)

(235 mm)

A.3/8" NPT dryer pipe

27" Wide Model

*5 3/4" |

|

|

|

|

| A |

|

|

|

| |||

|

|

|

|

|

| |

(159 mm) |

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 1/2"

![]() (38 mm)

(38 mm)

A. 3/8" NPT dryer pipe

Burner input requirements

Elevations up to 10,000 ft. (3,048 m):

■■ 120 Volt, 60 Hz., AC only, 15- or

GROUNDING INSTRUCTIONS

�For a grounded,

This dryer must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment- grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment- grounding conductor can result in a risk of electric shock. Check with a qualified electrician or service representative or personnel if you are in doubt as to whether the dryer is properly grounded. Do not modify the plug provided with the dryer: if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

■■ The design of this dryer is certified by CSA International for use at altitudes up to 10,000 ft. (3,048 m), above sea level at the B.T.U. rating indicated on the model/serial number plate. Burner input adjustments are not required when the dryer is operated up to this elevation.

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

9