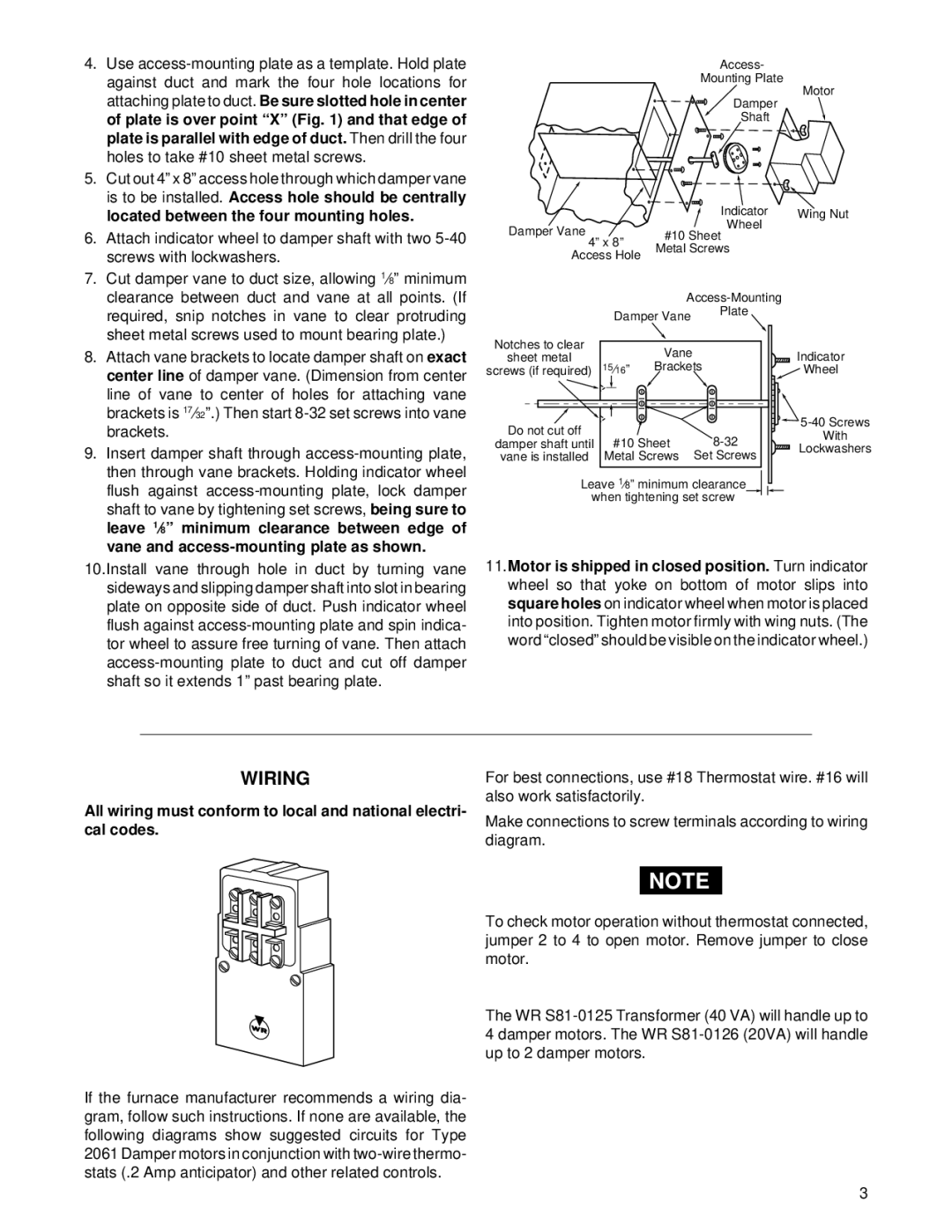

4.Use

5.Cut out 4” x 8” access hole through which damper vane is to be installed. Access hole should be centrally located between the four mounting holes.

6.Attach indicator wheel to damper shaft with two

7.Cut damper vane to duct size, allowing 1⁄8” minimum clearance between duct and vane at all points. (If required, snip notches in vane to clear protruding sheet metal screws used to mount bearing plate.)

8.Attach vane brackets to locate damper shaft on exact center line of damper vane. (Dimension from center line of vane to center of holes for attaching vane brackets is 17⁄32”.) Then start

9.Insert damper shaft through

10.Install vane through hole in duct by turning vane sideways and slipping damper shaft into slot in bearing plate on opposite side of duct. Push indicator wheel flush against

Access-

Mounting Plate

Motor

Damper

Shaft

|

|

| Indicator | Wing Nut |

Damper Vane |

|

| Wheel |

|

4” x 8” | #10 Sheet |

| ||

|

| |||

| Metal Screws |

| ||

Access Hole |

| |||

|

|

| ||

|

|

| ||

| Damper Vane | Plate |

| |

|

|

| ||

Notches to clear |

| Vane |

|

| Indicator | |

sheet metal |

|

|

| |||

15⁄16” | Brackets |

| ||||

screws (if required) |

| Wheel | ||||

Do not cut off |

|

|

|

| ||

#10 Sheet |

| With | ||||

damper shaft until |

| |||||

| Lockwashers | |||||

vane is installed | Metal Screws | Set Screws | ||||

| ||||||

Leave 1⁄8” minimum clearance when tightening set screw

11.Motor is shipped in closed position. Turn indicator wheel so that yoke on bottom of motor slips into square holes on indicator wheel when motor is placed into position. Tighten motor firmly with wing nuts. (The word “closed” should be visible on the indicator wheel.)

WIRING

All wiring must conform to local and national electri- cal codes.

For best connections, use #18 Thermostat wire. #16 will also work satisfactorily.

Make connections to screw terminals according to wiring diagram.

If the furnace manufacturer recommends a wiring dia- gram, follow such instructions. If none are available, the following diagrams show suggested circuits for Type 2061 Damper motors in conjunction with

NOTE

To check motor operation without thermostat connected, jumper 2 to 4 to open motor. Remove jumper to close motor.

The WR

3