1609, 241-2 specifications

The White Rodgers 241-2,1609 is a sophisticated thermostat designed for residential heating and cooling systems. Known for its reliability and user-friendly interface, this model stands out in the realm of climate control technologies.One of the main features of the White Rodgers 241-2,1609 is its easy-to-read LCD display, which provides clear visibility of the temperature settings and system status. This feature enhances usability, allowing homeowners to monitor and adjust their indoor climate effortlessly. The thermostat is equipped with intuitive buttons that enable quick changes to settings, facilitating a seamless user experience.

Technologically, the White Rodgers 241-2,1609 boasts advanced temperature control features, including programmable settings that allow users to establish heating and cooling schedules. This programmable functionality not only enhances comfort but also aids in energy savings by allowing homeowners to optimize their HVAC systems according to their daily routines. The thermostat can be programmed for different days of the week and can accommodate multiple daily settings, making it both versatile and practical.

The 241-2,1609 supports both heating and cooling systems, including conventional gas, oil, or electric systems, as well as heat pumps. This broad compatibility ensures that homeowners can integrate the thermostat into a variety of existing HVAC setups, making it a flexible choice for many households.

Another characteristic of this thermostat is its adaptive intelligent technology. This feature enables the thermostat to learn household patterns and adjust settings accordingly, providing enhanced energy efficiency. For example, if the system detects that occupants typically leave the house during certain hours, it can automatically adjust the temperature to conserve energy while maintaining comfort when they return.

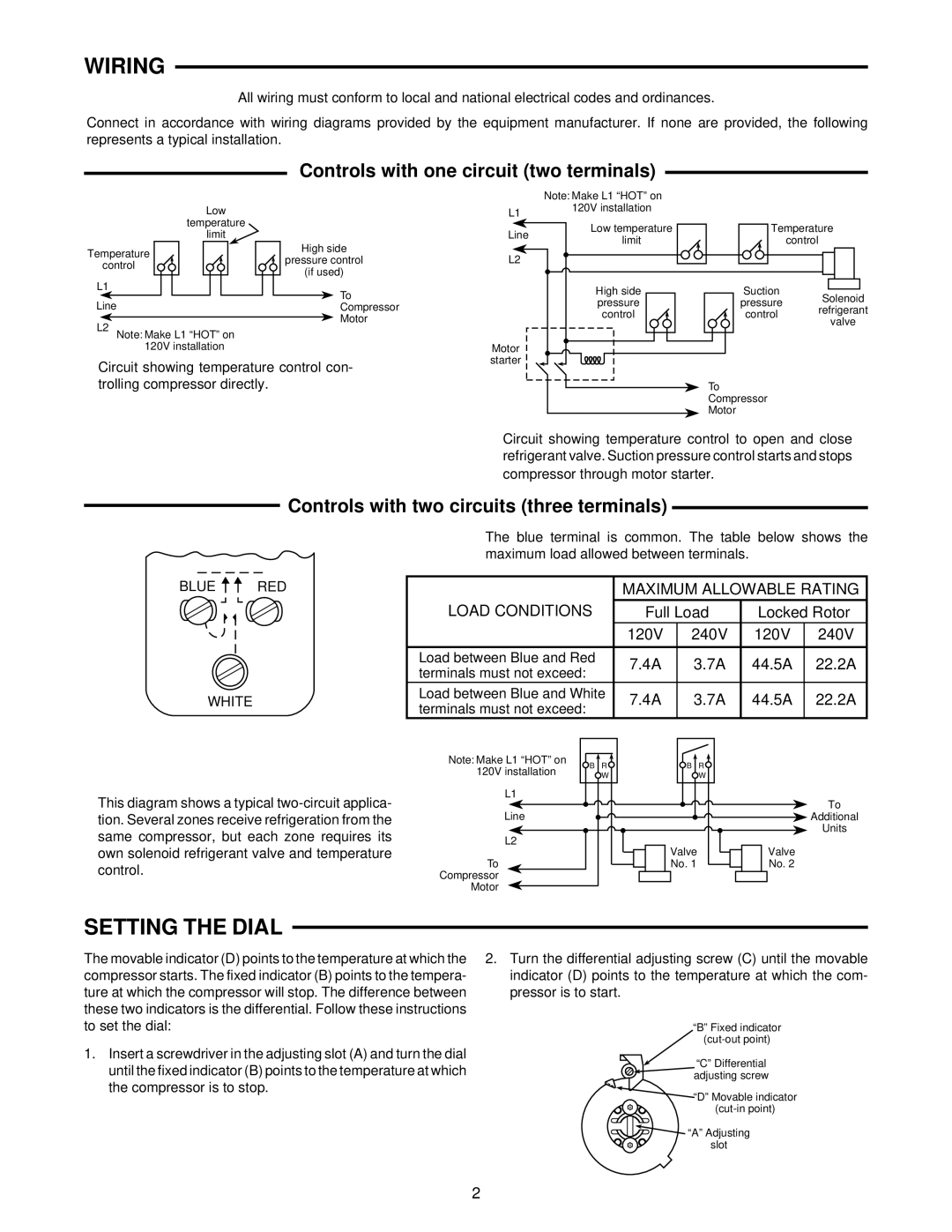

Installation of the White Rodgers 241-2,1609 is straightforward, thanks to its user-centric design. The thermostat typically comes with an easy-to-follow installation guide, allowing homeowners to set it up without professional assistance, provided they have basic knowledge of HVAC systems.

Durability is another hallmark of this model. Built with high-quality materials, the White Rodgers 241-2,1609 is designed to withstand everyday use while ensuring long-lasting performance. Moreover, the thermostat features a user-replaceable battery, minimizing maintenance inconveniences and enhancing longevity.

In summary, the White Rodgers 241-2,1609 embodies a blend of functionality, user-friendly design, and advanced technologies, catering to homeowners who seek an efficient and reliable solution for managing their indoor climate. Its programmable features, compatibility with various systems, and intelligent technology make it a noteworthy choice in the domain of home climate control.