668-451 specifications

The White Rodgers 668-451 is a versatile and reliable thermostat specifically designed for residential and light commercial applications. Known for its user-friendly interface and advanced features, this model has gained popularity among homeowners and HVAC professionals alike.One of the main features of the White Rodgers 668-451 is its intelligent control system, which provides precise temperature regulation. This thermostat can be programmed to operate efficiently through a 7-day scheduling feature. Users can set different temperature profiles for weekdays and weekends, ensuring comfort while also promoting energy savings.

The device is equipped with advanced humidity control, allowing it to maintain optimal indoor air quality. This feature is particularly important for homes in regions with varying humidity levels. The thermostat monitors the humidity and adjusts heating and cooling based on both temperature and humidity levels, offering a balanced environment throughout the year.

In terms of compatibility, the White Rodgers 668-451 works with various HVAC systems, including gas, oil, and electric heating systems, as well as central air conditioners. This versatility makes it an ideal choice for a wide range of homes and settings. It also supports multi-stage heating and cooling systems, ensuring peak performance.

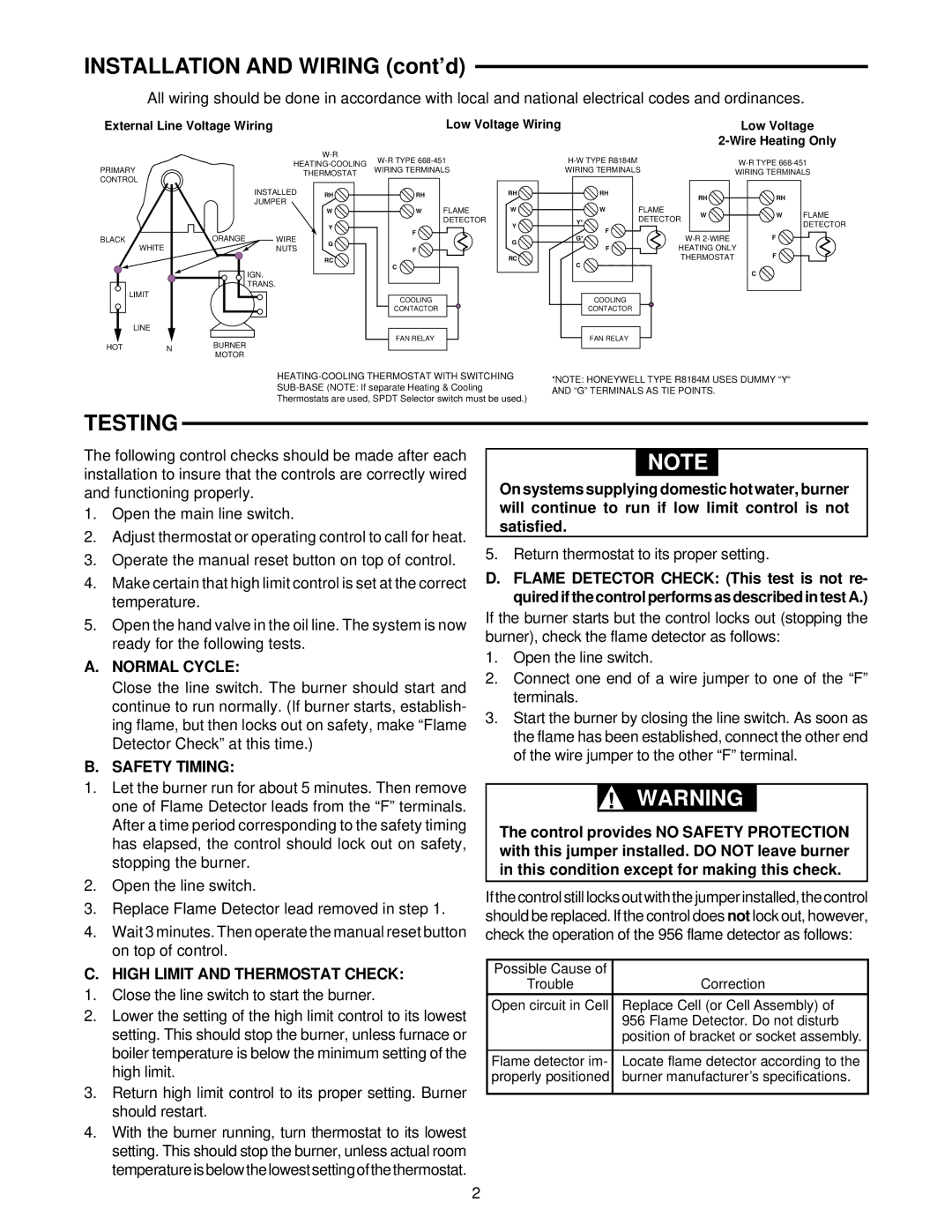

Another significant characteristic of the 668-451 model is its easy installation and setup process. The digital display is large and clear, making it simple for users to navigate through settings. Additionally, it features a simple wiring configuration, allowing for a quick and efficient installation even for those who may not be seasoned DIY enthusiasts.

The thermostat’s durable design ensures longevity, and it comes with user-friendly features such as a filter change reminder. This function helps maintain system efficiency and prolongs the lifespan of HVAC equipment by alerting homeowners when it's time to replace the air filter.

In conclusion, the White Rodgers 668-451 thermostat stands out for its advanced scheduling, humidity control, compatibility with various HVAC systems, ease of installation, and user-focused features. Its thoughtful design and functionality make it an excellent choice for improving comfort and energy efficiency in any residential or light commercial space.