First Firing of the Furnace

Start the furnace following the instructions given in the “Operating Instructions“. The initial pilot lighting may be difficult due to air trapped in the gas lines. During initial firing of the furnace, residual manufacturing grease will

Checking the Gas Inlet Pressure

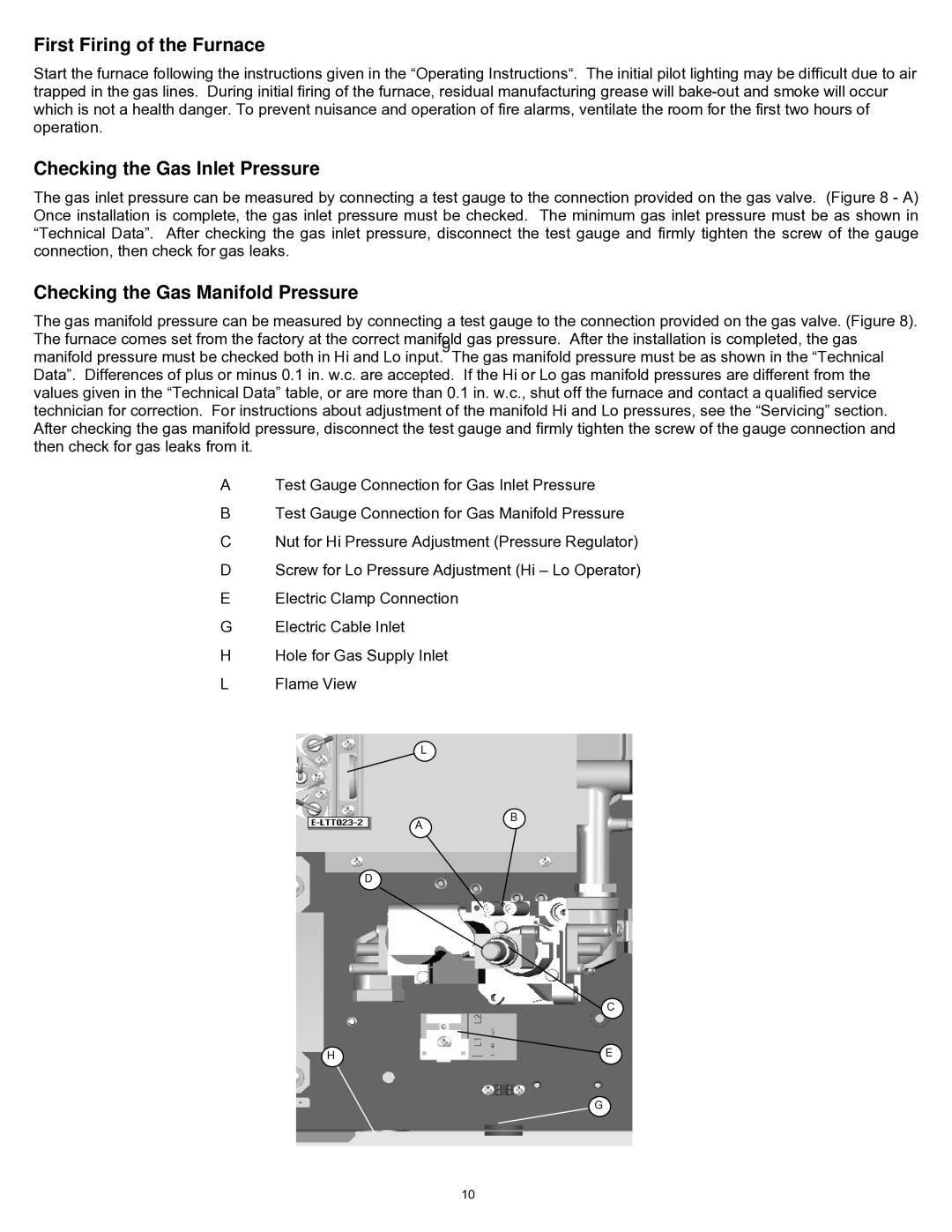

The gas inlet pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8 - A) Once installation is complete, the gas inlet pressure must be checked. The minimum gas inlet pressure must be as shown in “Technical Data”. After checking the gas inlet pressure, disconnect the test gauge and firmly tighten the screw of the gauge connection, then check for gas leaks.

Checking the Gas Manifold Pressure

The gas manifold pressure can be measured by connecting a test gauge to the connection provided on the gas valve. (Figure 8). The furnace comes set from the factory at the correct manifold gas pressure. After the installation is completed, the gas manifold pressure must be checked both in Hi and Lo input.9 The gas manifold pressure must be as shown in the “Technical Data”. Differences of plus or minus 0.1 in. w.c. are accepted. If the Hi or Lo gas manifold pressures are different from the values given in the “Technical Data” table, or are more than 0.1 in. w.c., shut off the furnace and contact a qualified service technician for correction. For instructions about adjustment of the manifold Hi and Lo pressures, see the “Servicing” section. After checking the gas manifold pressure, disconnect the test gauge and firmly tighten the screw of the gauge connection and then check for gas leaks from it.

ATest Gauge Connection for Gas Inlet Pressure

BTest Gauge Connection for Gas Manifold Pressure

CNut for Hi Pressure Adjustment (Pressure Regulator)

DScrew for Lo Pressure Adjustment (Hi – Lo Operator)

EElectric Clamp Connection

GElectric Cable Inlet

HHole for Gas Supply Inlet

LFlame View

L

A

D

B

| C |

H | E |

| G |

10